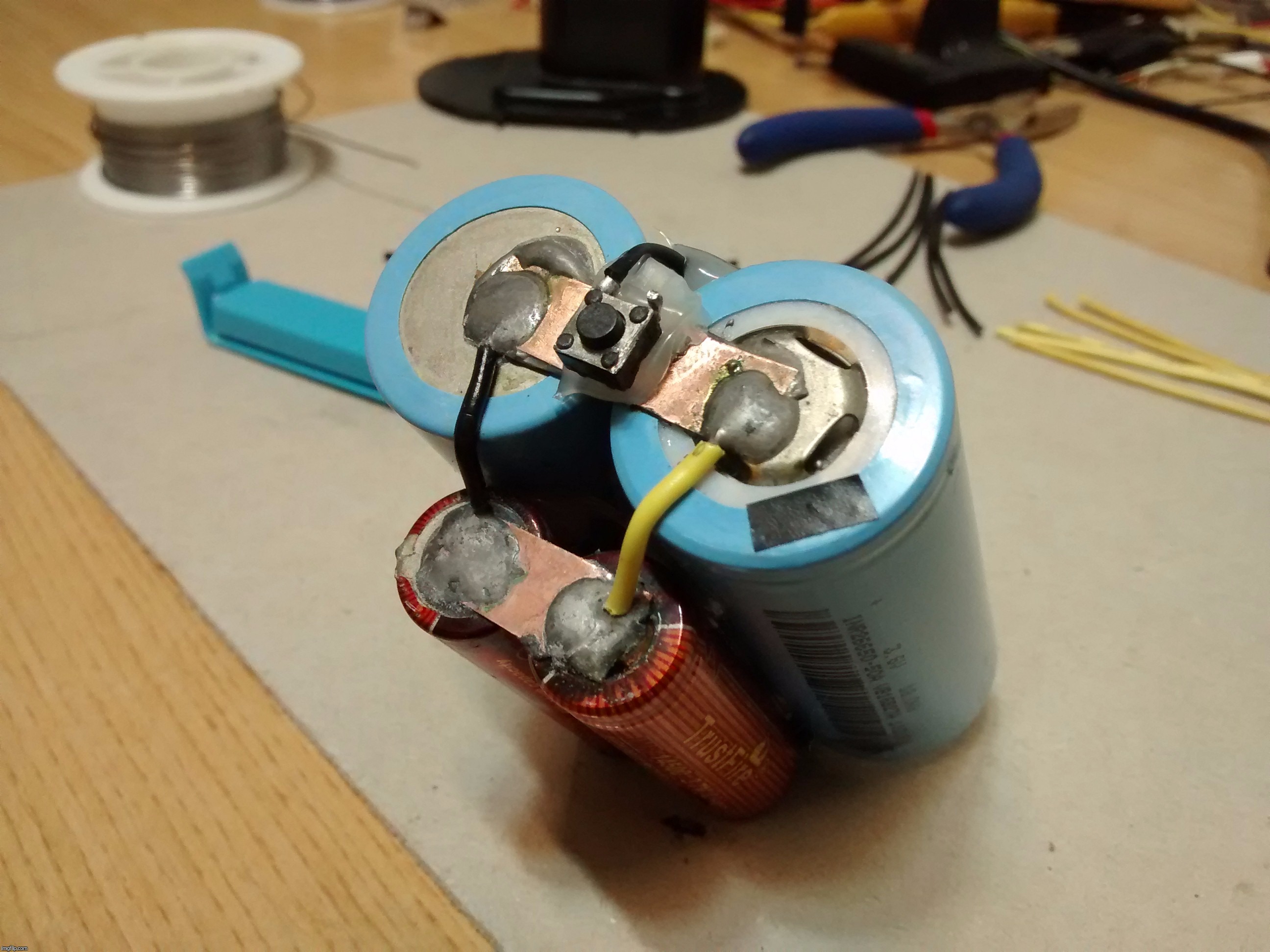

3 × 0.75mm² copper sheet above and one more below over the TrustFire IMR14500 700mAh (red-gold) teamed up cells.

Rose's metal all the way.

6 × AWG20 wiring up and down.

Copper sheet battery contacts.

Somewhat rearranged guts. Ended up adding more hot glue over the contacts' stuff before semi-low temp soldering the cables and closing.

Not fully tested yet, but the very little no-load voltage drop with the drill fully running (≈0.16V) tells me the stuff is working as it should.

Massive torque available now…

Cheers ^:)