As I was a good student in high school, I remember that aluminum and copper form a galvanic pair that overheats at the point of contact, oxidizing and causing electrolysis that leads to the destruction of the joint. But I often see flashlight hosts that combine aluminum and copper parts to make something attractive. Is this a good combination for the flashlight from a galvanic point of view? Or this effect is fully neglected?

“The beauty of anodising is that because it is an insulator and not a metal, it is compatible with all other common metals (from a galvanic perspective) by virtue of being non-conductive.”

“The galvanic reaction between Al and Cu is weak enough that even without anodizing, a layer of lube will stop it.”

“galvanic corrosion needs a wet environment”

Also aluminum immediately oxidizes in air and forms a thin but very hard non-conductive layer, stopping contact between copper and fresh aluminum.

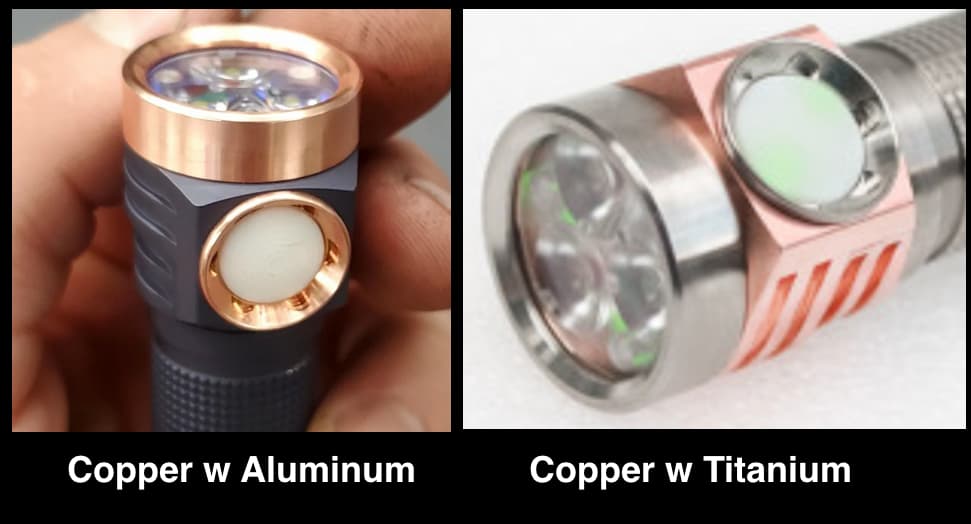

Except if you combine a copper head with an aluminum battery tube.

Use some Nyogel and it will prevent anything happening. Only Al/Cu has the potential for galvanic corrosion IIRC (of common materials lights are made from, that is); Ti isn’t reactive enough.

Thanks for your thoughts… I do use Nyogel…

what about Brass Contact Ring with Aluminum body tube… such as my TS10? I should worry about something? (I dont put nyogel on those areas)

Alu and Cu won’t readily react unless you add something else in the mix such as water, excessive heat or other chemicals.

If they did react there would be a lot of pissed off flashaholics… or manufacturers simply wouldn’t produce it.

Except for the threads, where the two metals are in contact. Otherwise the flashlight wouldn’t work.