The next step is a Copper C8… :bigsmile:

Nice work.

Me like. :bigsmile:

This remind me of :

The cooling power should be insane ! How about surface treatment to avoid oxidation ? Thrunite use chromium plating.

Oh man, that’s something you don’t see everyday.

Great work Bucket and congrats Dale! ![]()

So far no one has confirmed that the material used is copper by personal testing/judgment, on the outside is chrome plated but on the inside definitely looks like brass, there is no way one can mistake brass as being copper unless one is not familiar with those materials.

I have never been very charmed by the looks of the C8, but this copper piece transforms it into an awesome looking light

This looks nice but please (hope Dale will read this) make a new picture in a few weeks, if you do not polish the copper. I like the patina on copper - often it looks a little bit oldschool, but great :)

Here’s a couple patinas I got in a very short time. I’ve made other shades of brown but these are the ones I like most.

This chimenea turned black the first time it was fired up. Ten years later and rarely used, it hasn’t changed. The mesh and legs are steel. The rust marks on the copper is where the rusty steel was making contact and will go away in time.

This copper round was what I’ve been experimenting with. It went from a dull brown (naturally aged) directly to salmon overnight in a ziplock baggie with egg salad. The procedure actually calls for a freshly crushed hard boiled egg. The inset is how it looked right from the mint. The salmon color is my favorite.

Uncirculated but brown nonetheless, kind of shiny, just not like the freshly minted copy shown above.

I’ll probably let the one on the M8 age to better fit the military army green look of the baked host. Will also probably keep the one on the C8 Polished like a band instrument ![]() I’m a sucker for shine, love to polish stuff, been doing it for 40 years.

I’m a sucker for shine, love to polish stuff, been doing it for 40 years.

Have to say it again, this looks awesome and has to be the best way to do it short of coolant injection. A solid copper heat path from solder point to ambient and it looks original to the design. If I could cut threads I would do mods this way. Inspirational.

Scott, you should feel it in hand…that half pound of copper makes it REAL, feels like a club, and the output, OMG! 3226 lumens at 30 sec from a single emitter? It’s a beast, pure and simple, and yet low is very very gentle, read a book at night and not disturb anyone gentle. Pretty amazing.

Buck duplicated the original piece perfectly, with the exception of the added 2 fins that I wanted, it’s a carbon copy of the one Solarforce put in. But made of copper. And without the mass removed the way factories do it, leaving an air space above the driver doing nothing.

I don’t believe any factory or any big shop, anywhere, could have done a better job…at any price.

Edit: Stuck it in the lightbox for a quick 3 level read…after doing lux tests to the cell isn’t fresh

High 3543 lumens

Med 1001 lumens

Low 41.4 lumens

Sounds like they have a good home. My chimenea is slightly greenish (unlike the image shown) probably because of the more acidic environment outdoors. Your M8 might turn more reddish indoors.

Many years ago, we used a chromate conversion coating (Alodine) to protect aluminum aircraft parts from corrosion. It was a simple dip and let dry. Apparently, it can be used on copper also.

Having seen it done this way by Steve also it just shouts THIS IS HOW IT’S DONE in big salmon colored letters visible from the Magellanic clouds. Maybe it should be outlawed.

I have some clear coat for copper called Protecta-Coat. Not sure if I want to use it or not.

I’m working with an old Clausing and I’m a little apprehensive about using the automatic feed on it. Fortunately, I haven’t had any need for it in 30 years and just do everything manually. Here’s the model but not my video. I do have the upgraded tool holder.

Not sure if it’ll do metric threads but this video looks encouraging:

Good old Tubalcain! I've learned so much from his videos. I highly recommend them to anyone who wants to learn how to use a lathe. I also recommend Keith Fenner and Doubleboost's channels.

I think it has to be lacquer for it to have a chance to stick.

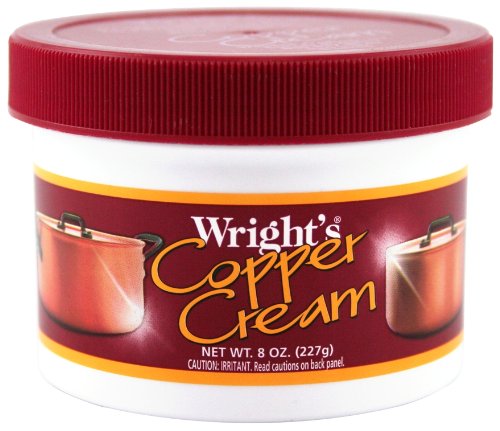

I found this on Amazon. It has a very good rating.

Protecta Clear is the best out there. Or so the research says. Even claims to protect against salt water.