Youtube must be jealous of buckets build ![]()

I personally think the light is just too good looking for the elves to handle, they can’t let go. ![]()

I'm wondering if the elves are boozing it tonight or what. I uploaded it again and it's been processing for a long time.

Working for me now :)

4-in-1, Videographer, Photographer, Machinist, Design Engineer. Tough job!

thanks for the info! Yup, front to back (side?) relief is tricky on such narrow tools. that’s a lot of front relief, I’m guessing because it’s for copper (softer?).

Thanks for the video Bucket. Very nice machining. Dale is a lucky guy. ![]()

Hey Steve, are you drooling all over my copper? Come on man, gimme a break! lol

You’ve had some pretty good experience with pushing the MT-G2 hard, what do you think? Will this copper exposed pill do the job? For a while? I have it set up at 6A at the moment, thinking of looking for more or even going direct drive at 12A, probably too much on that side and I do like options/modes so that might be just a test run. Would love to hear your opinion of how this ought to work…

I get to start stalking the mail carrier tomorrow, yippeeeee! J)

I’m looking forward to reading about the outcome of your experiment. You could use it as a snow remover. ![]()

66º here today! lol So with your own experience, how do you think this copper pill will do?

I’m realistic enough to know that above that 6A it’s just going to be difficult to control the heat that big emitter makes. 12A? Yeah right! For 12A it needs active cooling. Refrigerant even.

I’ll have to run more extensive tests on this than I have in my spreadsheet, like I did for the Trifecta lights, and do a side by side comparison vs. the stock pill with a 1/2” thick copper boost in the pill (that’s how I was running it when I sent it to Buck) I’m thinking about putting a new emitter and driver in this copper “pill” and having both pills in working order. That will make it easier to do side by side comparisons. I’ve ordered the emitter and driver so that I can do this. Hopefully next week I’ll have everything together and be running some tests.

I cant answer your question Dale. My monster lights copper pill was from memory about 30mm in diameter and around the same length. This was screwed into the heatsink which was 85mm in diameter with 2.5mm width cooling fins running to a depth of about 8mm from the pill. With the 9 amp driver on medium this thing still gets hot. I think medium was 33% of high. You are in uncharted waters my friend. Maybe the copper by itself will work better than being surrounded by aluminium.

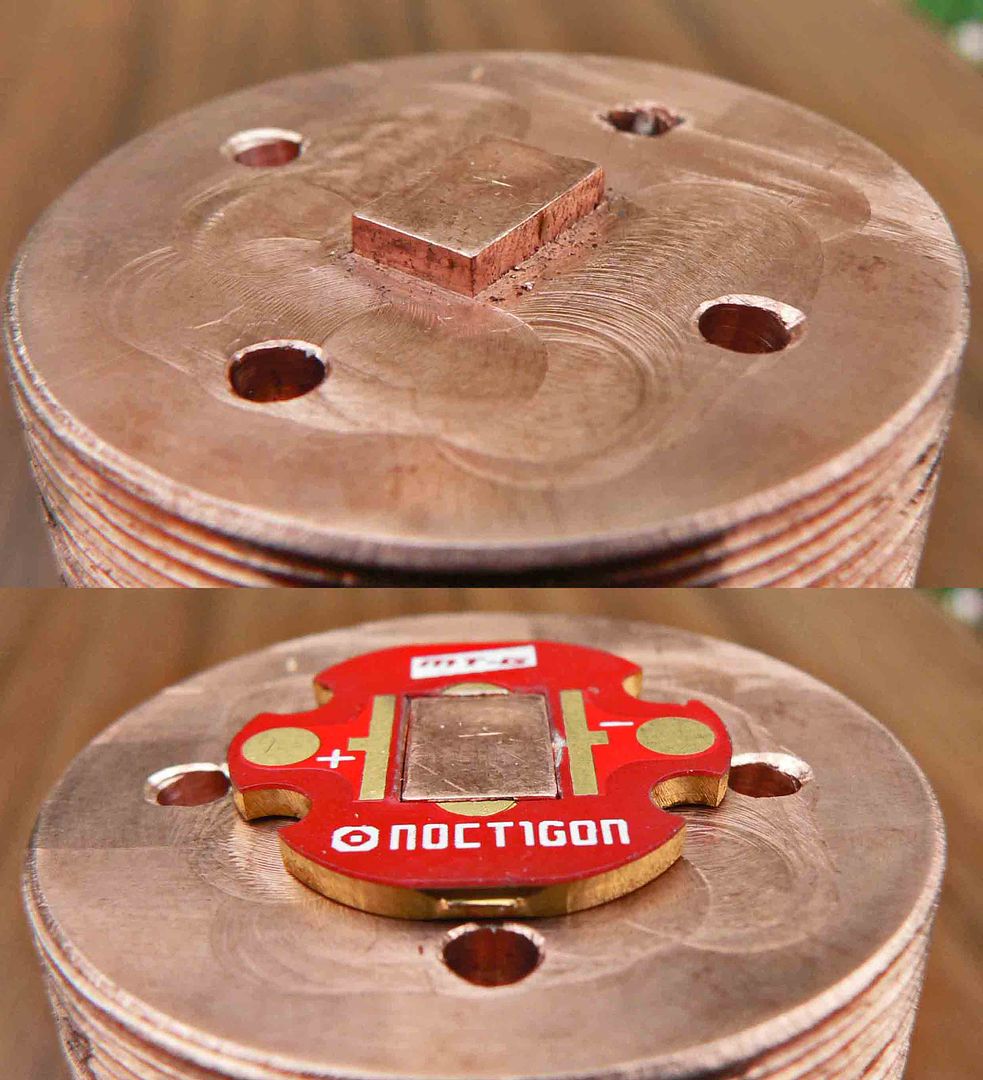

I think this should keep 6A happy enough, start-up there was around 2630 lumens, but it dropped rapidly in my previous set-up. If it can hold close to 2500 lumens, maybe down to 2400, in 3 minutes or so, I’d be happy with that. It dropped 314 lumens in 30 seconds before…2636-2322. We’ll see what this 8 ounce piece of copper does for it. Should be a lot better. With the Noctigon directly on copper, and that copper being finned and exposed, yeah, it should do a lot better. (my previous test only shows the results at 30 seconds, didn’t take it further)

Heres a shot of mine. The led was soldered directly to the pill along with the star.

Heres a shot of mine. The led was soldered directly to the pill along with the star.

That’s impressive! I reflowed my Noctigon to the copper along with the emitter in my K3 and a couple of others, will do that with this one from Buck as well so it’s a solid continuos piece (more or less) Even did that with the 3 C8’s with Ryan’s pill. I figure the solder joint has to be better than a compound or adhesive.

That’s the way to do it right there, absolute direct to the pill thermal path. I know someone that’s doing that in a production light, to be released this quarter.

I know I have seen that done some where before. ![]()

![]()

Match was the first person l saw do it but could not work it out until OL did a similar thing. ![]()

Closest I came to that majesticness was a solitaire with awg 12 solid drilled through the center pad of a 10mm mcpcb. This is mind blowing.

They have today as the delivery day, but don't have any updates after it left the last facility in PA.

I'm hoping!

I've looked at that picture a hundred times. I'd like to do the same island but eliminate the nocitigon all together by soldering tabs directly to the die. Maybe masking the copper on the lower shelf with shellac or something. I'll tackle it someday.