Has anyone tried a small Christmas sphere as a Wavien collar? those things are super shinny on the inside…

Has anyone tried a small Christmas sphere as a Wavien collar? those things are super shinny on the inside…

How can you cut a Christmas ball in half without shattering it in a 1000 pieces?

The same way you cut a bottle I think, use a piece of string soak it in alcohol, tie it around the sphere, light it on fire, wait a few seconds then immerse it in ice cold water, the thermal shock will cut it in half… There is a video using this method on a bottle, I’ll see if I can find it.

Here it is

something like this ??>>> https://www.youtube.com/watch?v=oZAgHL9zpGM

Yes

Interested in both ideas, so looking forward to seeing how you get on! ![]()

I suspect the light being reflected back from low angles, angles approaching 90degrees to the emitter, isn’t the most effective in terms of recycling. Appart from less light being emitted at those angles anyway, I suspect it will be rather inneffective to try and focus that light onto the thin sliver of emitter that’s visible from those angles. Also in my case with the sbt-70 any light hitting the glass window at glancing angles will likely bounce off entirely.

I’m mostly worried about capturing and reusing the wasted light in the 20 or so degrees either side of the central “lens hitting” cone.

Here is a diagram of the wavien collar. In case anyone isn’t too sure what we’re looking for.

Have you looked inside? All the ones I’ve seen are super shiny looking from the outside, but inside the coating is rather dull and quite yellowish/gold.

The super shiny coating that you see from the outside is formed on the inside of the glass, but then they tend to cover that coating in protective coats which aren’t anywhere near as reflective.

If you find one that’s as shiny inside as outside it could work quite well.

Wow, so many comments I missed most of them ![]()

This is going to be a critical aspect for any collar, dialing in the focus (height above emitter) is going to be required on all of these. Shimming and precisely mounting is something you wont get around unless you machine one to spec. Don’t see it as a big problem though.

The ones I broken and got an earful from my wife had a shinny silver coating inside, just like a mirror…

Linus, why would you leave the glass window in place? Remove that so you can reflect light back onto the die itself, otherwise the wavien collar is pretty much a moot point.

Linus, why would you leave the glass window in place? Remove that so you can reflect light back onto the die itself, otherwise the wavien collar is pretty much a moot point.

I’ll remove it as a last resort but only if I see its causing a real issue with the reflected light. It’s certainly not ideal I grant you, what with having the light pass through it on the way out and on the way back. But the window is rather thin, AR coated and pressed directly onto the phosphor so I’m not sure how much real harm it will actually do.

Did you do any lux/output testing, before and after removing the window off your first SBT-70?

Leaving the die exposed completely is not something I’ll do unless I really see some serious issues with the output.

I intend to be able to remove the head off the light to show off the mounted led directly and I need that glass window there for piece of mind. Too many slipping solder tips and pokey fingers in this world! ![]()

Can’t be showing me horrific images like that and then expect me not to learn a lesson from it ![]()

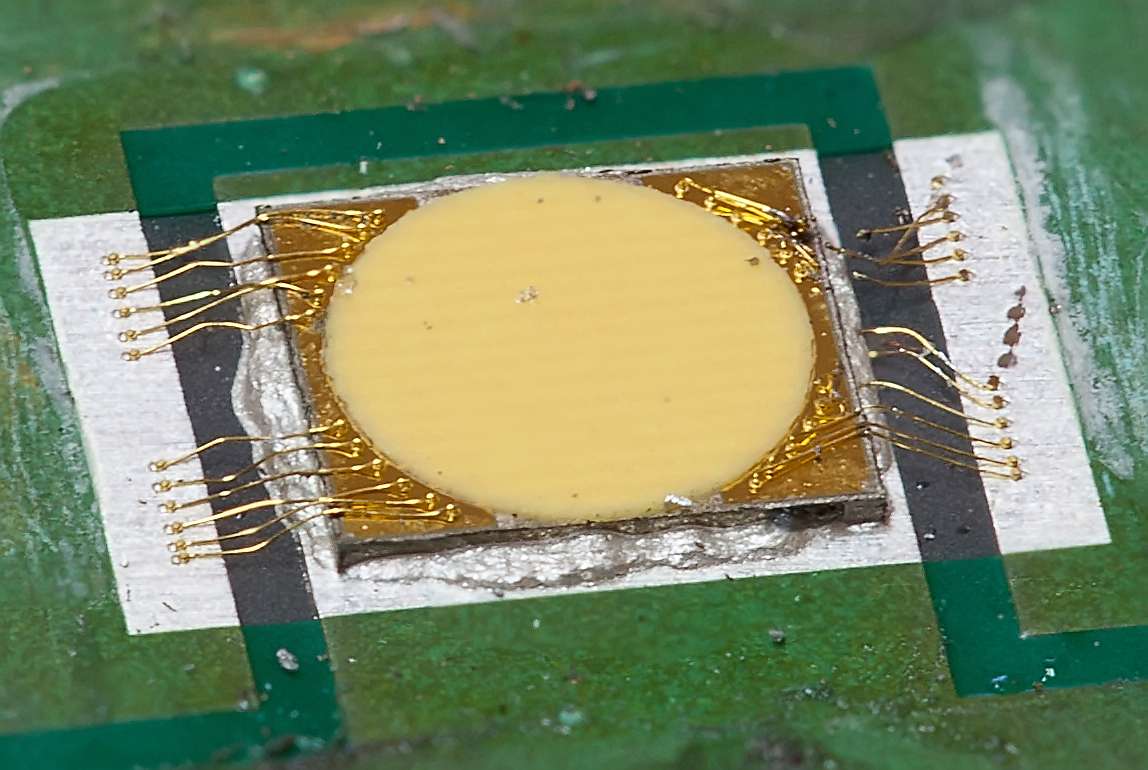

I shoulda tried a solder blob on each side, covering all those wires, and then a 20ga Silicone wire bridging… that would have been interesting huh? Do I still have that or did I throw it in the bin of shame file it in the circular file of insanity?

I shoulda tried a solder blob on each side, covering all those wires, and then a 20ga Silicone wire bridging… that would have been interesting huh? Do I still have that or did

I throw it in the bin of shamefile it in the circular file of insanity?

Hehe, bin of shame ![]()

Yeah definitely, see if you can rescue the poor thing. I’d be very interested in the results.

If that method has any chance of working it’s going to on this one with those large gold pads.

I shoulda tried a solder blob on each side, covering all those wires, and then a 20ga Silicone wire bridging… that would have been interesting huh? Do I still have that or did

I throw it in the bin of shamefile it in the circular file of insanity?

I though something very similar when i saw this picture today, i just read today that old thread where you revived an XM-L with torn bond wires with some radio shack liquid solder ![]()

I hope you did keep it, but i do that also something when i mess up a project, i just trash it to not have to see it, or place it somewhere and almost completely forgets where i put it.

I do still have it, but reviving it is out of the question. Trying to solder it leads to a direct short on the battery. So, to keep myself from further possible damage, I pulled the silicon chip off the substrate. Beyond repair without a magic wand.

I do still have it, but reviving it is out of the question. Trying to solder it leads to a direct short on the battery. So, to keep myself from further possible damage, I pulled the silicon chip off the substrate. Beyond repair without a magic wand.

Too bad, had my fingers crossed it would work. Sounds like you may have bridged the top gold pad with the bottom pad below the substrate and shorted it out that way. Too damn fiddly when things are so small. RIP ![]()

—

With regard to the Christmas ornaments. I could see it working well enough, depending on the type you have and provided you have a good way of cutting them down to size. The bottle heat cut is cool but it doesn’t strike me as particularly accurate/controllable. Maybe it can be used here. No idea.

I took another look at the christmas decorations box and you’re right that the inside coating can be pretty mirror like on some of these. The big ones are especially nice.

The small ones I have here vary greatly in the overall roundness/smoothness and quality of the internal finish. Some are quite milky inside and the glass looks a bit “blobby”, but it may not be that much of a problem. Has anyone gotten these balls to work before?

They’re about 30mm in diameter so the size is pretty great and I had started wet sanding one down (didn’t like the idea of attempting to cut/dremel the thing dry and getting glass dust everywhere), but I switched to the idea of polished aluminium when those cups showed up. Thinking that would be an easier proposition.

It all depends on how shiny you can get that metal vs dealing with the glass.

I’m really hoping we can come up with a good DIY approach for this collar business. Would be cool and there’s quite a few avenues to explore already! ![]()

Since my exploits conerning the SBT-70 failed to materialize in the fashion I had intended, this afternoon I wedged it into the SupBeam K50. The big reflector works well with it, down in Moon mode the blue lines around the periphery show in the reflector and it’s pretty awesome to behold! Even the fancy suspension bridge work with the bond wires shows in the reflector. Works for me!

Pics, it DID happen! ![]()

Looks great in there! Bet the hotspot is lovely as well ![]()

Well, it’s not a super fathead Courui but it does the job. ![]() lol

lol

Another possible source for ready made and polished atainless steel collars could be something like this.