Wanting to approach nighttime surfing started investigating my options… All being really expensive…

So started reading up on LEDs and drivers and water cooling and so on.

The initial iteration was using a CXB3590 from Cree. Went for a reflector style model but ended up not wanting to purchase and retrofit an existing reflector so tried 3D printing an tried different type of reflective sprays.

The heat from the COB turned out to warp the closest part of the 3D printed reflector.

Read up on high bay LED applications and that the sweet spot is to use different beam angles and values closer to 5 - 10 degrees so really using a reflector for a large COB chip wasn’t a great idea to start with. Learning by pain?

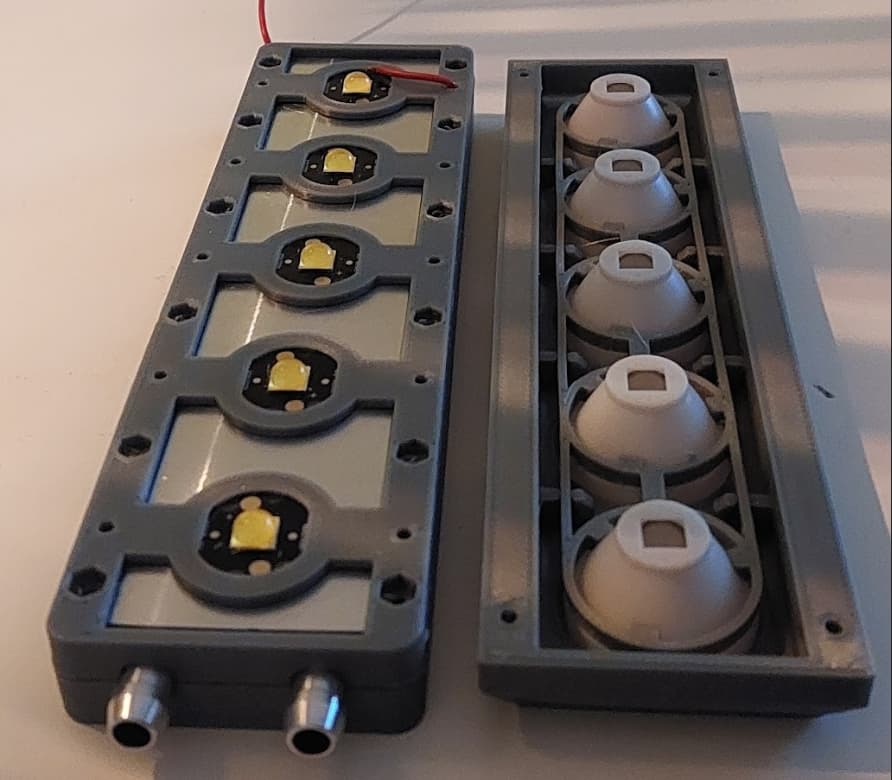

So next iteration was using smaller LEDs and optics.

Haven’t really figured out the proper beam angle for the location where I’m planning to do nighttime surfing so found optics with the same form factor but many different beam angles that could be tested out later on.

So wanting to come close to 200.000 lumens I found a LED chip Cree XHP70.2 on MCPCBs from KaiDomain.

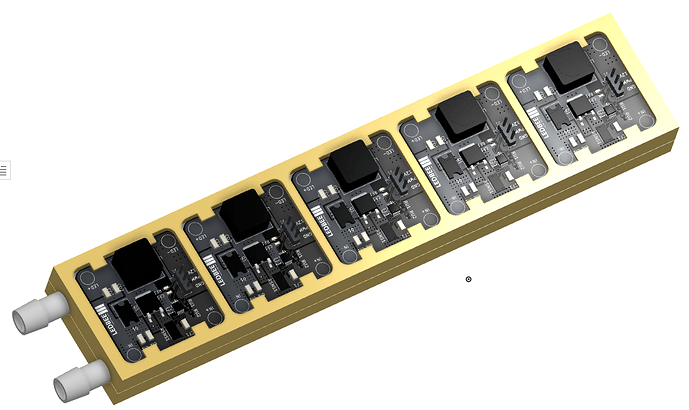

Ordered 10x to start with. Looking to build 4x “flashlights” using 6x LEDs and drive them a bit over spec using water cooling.

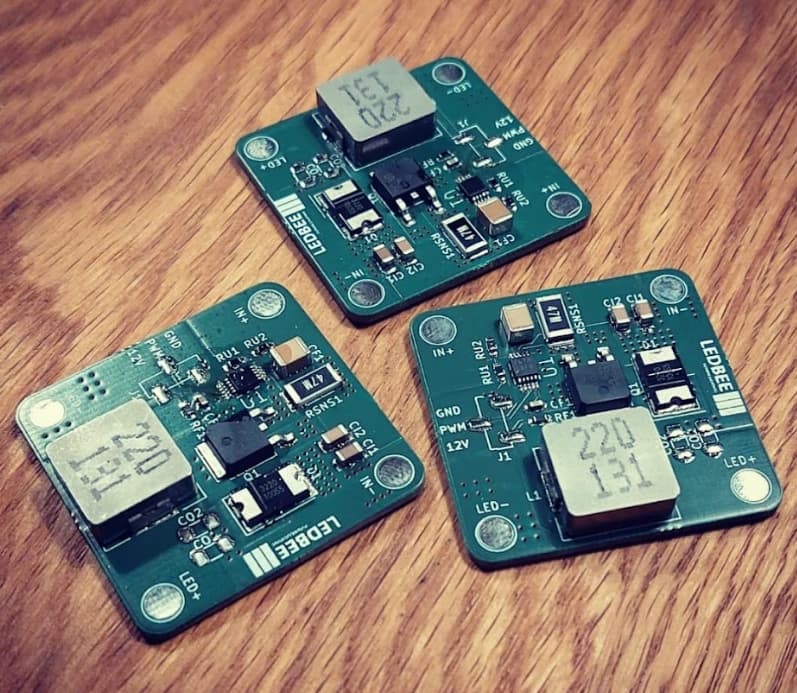

Now to the driver part. Looked at existing options but came to the conclusion (mistake…) of rolling my own…

Went for a 1-1 to achieve a “simpler” more low-amp board … So one driver per LED…

Investigated further and locked on the LM3409 from Ti since they always have great documentation.

I’ve built 5 sets of drivers and tested them individually and they seem to work fine. But my problem now is when I mount them all in my “flashlight” housing I’m experiencing an issue I haven’t been able to resolve.

Long into…

Once mounted, I control each driver/LED using a dedicated PWM signal from my MCU … But when I turn on LED #1 all of my LEDs light up…

I’m using a Polycarbonate (PC) filament and I’m trying to figure out if that PWM signal is somehow traveling via electrical properties in the “plastic”. But at the same time statements about PC filament is “It is also a good electrical Insulator so you can use it to design Electrical instrument boxes.”

But as soon as I loosen my 3D-printed housing things work as expected… So strange…

I initially printed the housing using PLA but the MCPCBs get hot and deform/warp the PLA parts that hold the MCPCBs against the cooling block…

Any ideas on steps to troubleshoot? Looked for other filaments to try but PC is hard to beat for it’s heat-resistant properties…