Hi folks,

I plan to mod a Fenix HT32 (21700, white+red+green LED) to accept three LEDs on 16mm MCPCB.

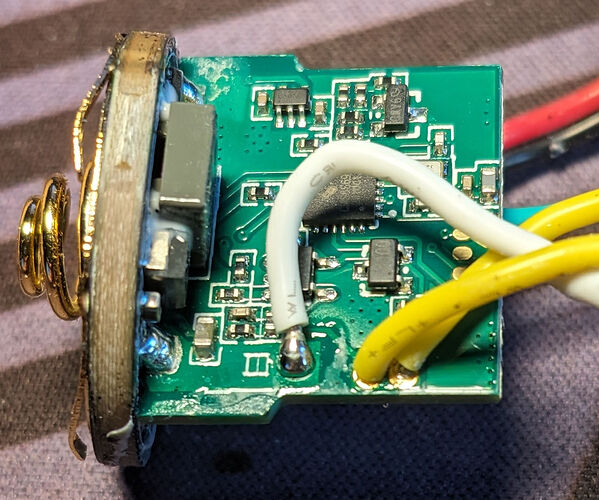

I want to keep the original driver, it puts out 11W - 15W - 17W on white - red - green channels, and 30W on white turbo.

I’d like to have steady 17W output, but even the original setup steps down to a continuous 10W after 3 to 5 minutes.

I drew three heatsinks. They all bring the 3x 16mm MCPCB close to the lens, as I will use individual small optics and aim for a 90° floody beam.

a) a simple round cylinder, 61g, good contact to host with screws. Head needs machining.

b) same, but less material, 37g.

c) this heatsink is only held/pushed by the lens and screwed on bezel. 29g, the head needs no machining.

Playing with thermal resistance, area and thermal paste thickness, I calculated 13K delta for a), 17K for b) and 10K for c). The temperature the LED die is above the host temperature, that is, at 30W (which are, originally, only for a few minutes).

Do these numbers seem plausible?

Looking at the Fenix and 1lumen runtime/temperature charts, the internal delta of LED-to-host doesn’t seem to matter much, as the host itself will heat up so much that the light stabilizes at around 10W output (for 2h).

That would be lower than I wished for. But at least my preferred heatsink c) would be suitable, without machining the flashlight head?

How do these bigger flashlights normally handle 10W, 30W? Would potting the driver, with better thermal contact to the host, help? Is Fenix too conservative with a host temperature limit of 55°C?

Or is 20-30W sustained for 1h simply not realistic without active cooling, in a medium-sized flashlight

Any insights and thoughts are much appreciated!

Ivo

[originally posted on Drehteil, gute Wärmeübertragung? | Taschenlampen Forum and moving here to BLF]