As is the case so many times there were a couple of reports of new stuff here that I just had to try! ![]() djozz reviewed the new XHP-50.2 and TexasLumens was looking at the 20700 cells, so I figured I’d build a light and try both of those at once. This is my 5th full build from scratch, hence the name, and while I’m still on the learning curve with the lathe I think it’s working out pretty well.

djozz reviewed the new XHP-50.2 and TexasLumens was looking at the 20700 cells, so I figured I’d build a light and try both of those at once. This is my 5th full build from scratch, hence the name, and while I’m still on the learning curve with the lathe I think it’s working out pretty well.

Initially I made a battery tube from thick walled 6061 Pipe that would easily hold the 20700 with room for the 21700 when those become available. Getting the light completed to a fair simile of the design showed me that I needed to make some changes.

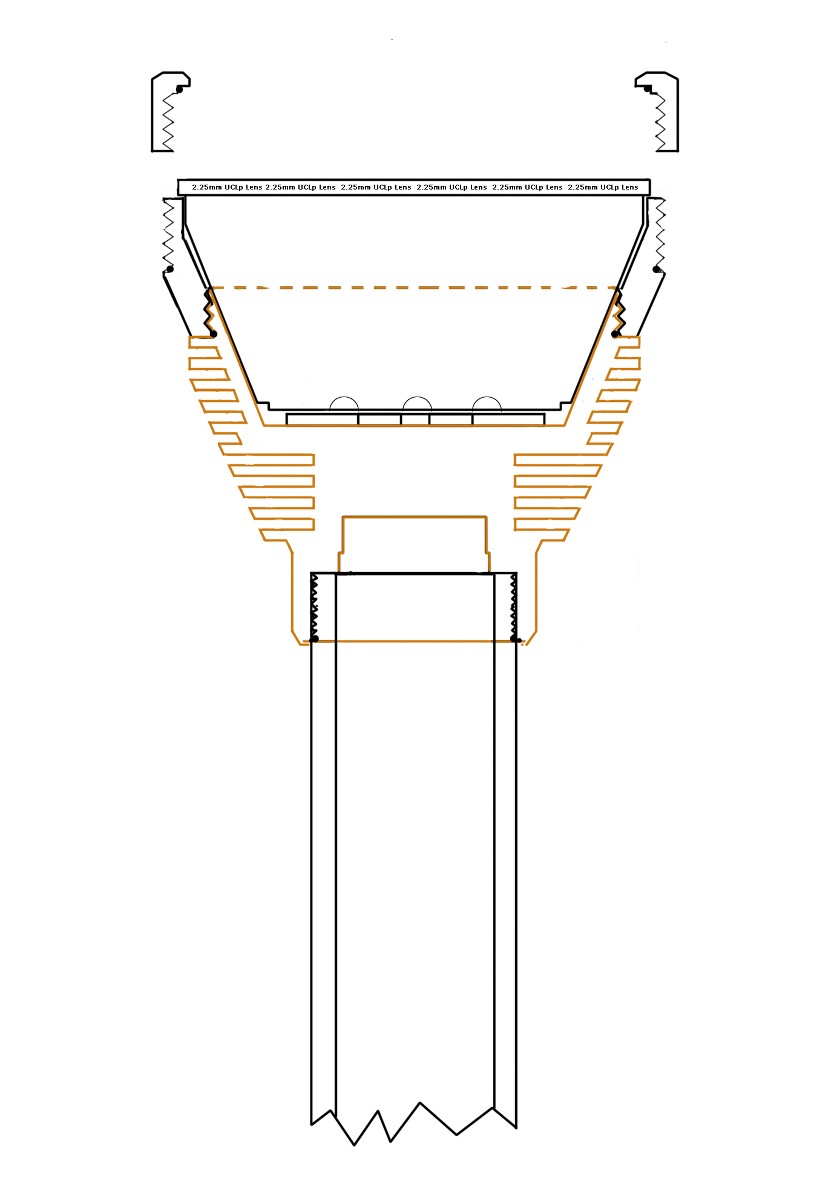

Here’s the design…

I don’t have autocad abilities so this is mocked up in Photoshop to scale.

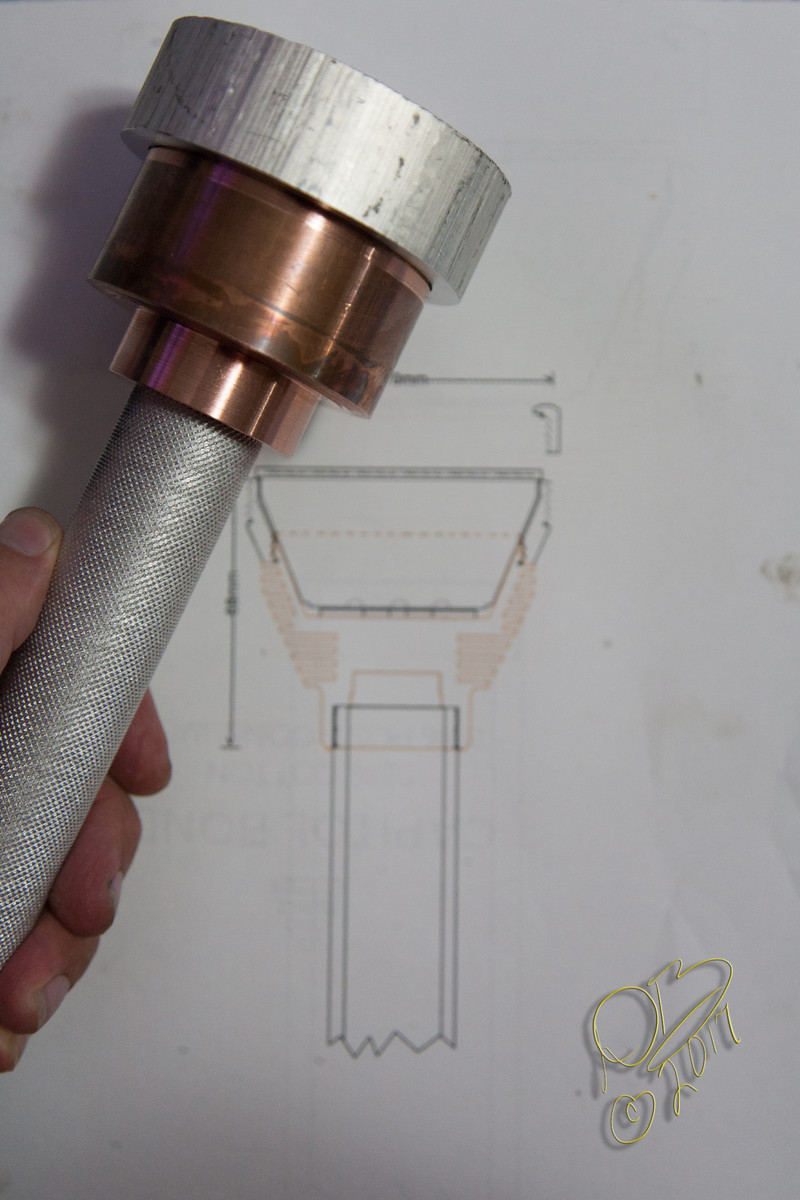

I ordered the materials, including a 3.17 pound chunk of Tellurium Copper for the head. First draft, getting the knurling on the tube and getting the copper semi sized to fit the triple reflector from KaiDomain. Since I didn’t have the reflector and emitters I wanted to just get it close first, to save some time later when the other parts arrived…

As you can see, I was trying to utilize some pieces I already had here, so I mated the larger diameter aluminum bar stock to the top of the Te/Cu to accept the 63.7mm reflector. ( the Te/Cu was the largest diameter piece I found at my supplier online)

Then I did about 90% of the stock removal in the copper for the big reflector…

So, I’m really bad about finishing a project in one continuous process so I don’t forget what I’m doing, but in this case the above parts were set aside and I had to wait a couple of weeks for parts to arrive. A lot went on in the meantime, including a 1600 mile trip out of state to shoot photo’s of my nephew’s wedding. When we got home, parts had arrived! I jumped right on the light, (they were on their honeymoon, figured they had other things to worry over than pictures!!)

And this is the initial result…

The triple XHP-50.2’s made numbers like this with the 20700B (the high capacity version of the Sanyo cell, the A variant wasn’t available)

0.18A for 122.13 lumens

0.42A for 333.96

1.22A for 941.85

4.67A for 2839.35

9.01A for 5147.46

15.25A for 7866

with a 30 sec showing of 7728 lumens

I then bypassed the spring on the driver and got it up to 20.34A and 9108 lumens. Still a long ways from what I had though this new emitter might do.

So I machined a copper spacer to act as switch retaining ring and got it up to 10,488 lumens with a 30 sec showing of 10,005 lumens

Hmmmm, still not there. So I tried a pair of Sony VTC6 cells. These showed me 21.12A and made 11,695.6 lumens. Better! Of course they fall like a ton of bricks, so I decided to rebuild it.

The piece of 3” pipe I used to make the bezel, initially, left very little shelf for the lens to seat against. Figured to make a new bezel and a 26650 battery tube…

So now, with a thicker walled and nearly exact external diameter 6061 pipe I was able to get a nice wide shelf for the lens and put an o-ring groove into the face of the shelf. So the lens is sealed up top. This is an UCLp lens from flashlightlens.com

You can make out the o-ring at the lens in this side angle shot. The bevel on the bezel is the same angle I used everywhere there was a bevel, this is the angle the reflector required to mate up in the head.

In this next shot you can see how I sleeved the bezel to allow a difference in lens thickness, the UCLp is 2.25mm thick but a lot of good glass out there is 3mm or more, so I allowed for a few mm of play in case I wanted to change lenses later.

The 3 XHP-50.2’s in the KaiDomain reflector

The overall modified light with it’s 26650 battery tube… I’m not good at knurling. I know there are diameters that work well with a given tool and there are diameters that do not. For the first time I tried using the feed on the lathe and started the knurling tool at a fairly deep set. This resulted in a tight spiral groove with the opposing steps stacked and killing the diamond pattern. It feels good in hand, doesn’t look bad unless you look really close, but it is what it is…

Since I had already done a lot of work on the tail cap with the smaller tube and had some copper invested in it, I decided to salvage the switch mechanism and copper of that previous version. To do this, I simply cut threads right into the knurled tube! Using it as a plug to thread into the larger tube and cutting a matching ramp in the opening of the bigger tube allowed it to work. Makeshift, perhaps, but it works. ![]()

So now it takes 26650 cells, waiting on some new LiitoKala 5000mAh 26650’s to arrive from GearBest.

Initial look at a pair of Basen’s shows me 11,247 lumens. Still in the ball park with more capacity.

Hope to get some beamshots tonight but it’s been raining so it might be later in the weekend.

Thanks for cheking it out! Lot of work in building a light, probably have 20 hours in this what with a couple of screw-ups on my part. And so the learning curve continues…

Edit: Beamshots added 3-26-17

This is from the same ol Canon G1X camera, 4 times faster shutter… ISO 1600 at F/5.8 with 1/8 second shutter in Manual mode on the tripod. First is 28mm equivalent, second is 112mm equivalent or 4X.

The red 55gal oil drum is at 97 yds, spring is fully upon us so everything’s getting bushy! lol

/Samsung%20INR21700-30T%203000mAh%20(Gray)-Capacity.png)