xpg2 to 18650, nothing inbetween. I have sinkpad to copper pill. Is there anything wrong with doing this?\

The battery is from a laptop pack.

xpg2 to 18650, nothing inbetween. I have sinkpad to copper pill. Is there anything wrong with doing this?\

The battery is from a laptop pack.

I don’t see a problem. The heatsinking has got to be very good. I would try it with an emitter you don’t care about first, just incase. I would also discharge the battery a little to lower the voltage a smidge just to be a little safer.

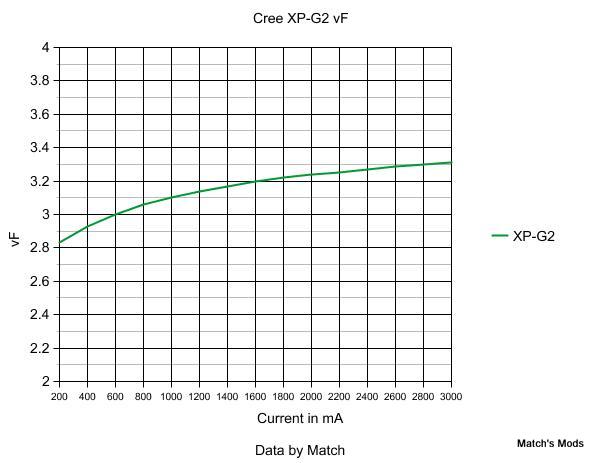

The problem you can see in the bottom graph, the Vf scale. That’s the Voltage.

Freshly charged 18650 cells are 4.2 Volts.

You will have to burn off the surplus with a series resistance (a resistor or a current limiting device) or burn your LED.

Put an Ampere meter between LED and batt. Then you can see what’s happening.

I have a battery discharger. Should I discharge to like… 4v? What about voltage sag? At 3A, my battery sags .5v i think so 4.2 to 3.7 at 3A. But the first few seconds of operation, the battery doesnt sag, so that is going to pop my led. Do you have any ideas on what I can do?

Get a driver circuit.

![]()

Others can tell you what’s best, I wouldn’t know for sure…

By the way, if you have more than 1 cell, you can parallel them, but then you will need more resistance too…

Maybe you’ve heard of the AMC7135?

It’s a tiny 350mA current limiting chip.

You can parallel them, each 7135 adding 350mA.

It’s quite common to use 8 of them to drive an XM-L(2) from a 18650.

I actually have like 40+ amc7135’s, but I hate using them because they take up space and get hot.

There is no problem running that setup without the amc chips. Battery sag ensures your xp-g2 does not burn up.

Gonna run HOOOOOT!

1400mA in a UltraFire 602C body and the little thing gets crazy hot…direct drive is going to pull ALOT more than that and probably burn that guy out

With that said…after I reflowed my XP-G’s to copper sinkpads, I tested them with a 3.6~vdc battery, just touched the contacts to ensure they came on…but didn’t run them that way!

Solution…get a 101-AK-A1 from FT and run it like that….otherwise I don’t suspect it will last long

I just tested Direct drive on one 18650 with an aluminum xpg2. I mounted the xpg2 on a piece of copper pipe. After 3 mins of DD, the copper gets pretty hot to the touch. I also have a mode for 2.1A. The 2.1A at 5mins is only slightly warm. On DD, my DMM measured only 2.7A D: D: D: D: On the 6x AMC 7135 I got 1.7A.

1.7A might be your wires from the driver to the star

gonna run VERY hot and on a stock aluminum star with the substrate between the emitter and the metal the LED is going to run MUCH hotter than it would if it had direct heat bonding

Let’s hope it stays running

Crazy bright when you hotrod em huh? ![]()

yeah so much throw, i love it. It seems to me that aspheric throws much more than a reflector becaise the reflector’s beam is fatter. I tested this by shining the light into the sky. the aspheric has a beam that is brighter. Any suggestions?

The beam from a big reflector or big lens is tighter than with a small lens or reflector.

It may be wider at the start, but it stays that wide when you have big optics.

So it’s not about the wideness but about the tightness.

Reflectors really don’t focus the light, they more or less “direct” them out the front, the aspheric collects the light then focuses it into a beam, this is why when you zoom you are actually getting more lumens as it’s doing what it was designed to do, in unfocused mode you get the big floody beam because it’s not focused. Another focusing type lens is a Fresnel lens.

In order to run that high current for extended periods without emitter damage I say reflow to a copper sinkpad/noctigon, make sure it’s bonded well into the pill

Yeah, I plan to reflow emitter to a sinkpad. Anyone got any ideas on how I will put my lens or reflector on my light? Tape is there is hold down led to copper cap.

Is there some kind of clay or etc that will stick to copper? I can drill mini holes for more support

I got nothin’ ![]()

I'd run a more beefy driver than that for an XP-G2, I use the Int'l Outdoor 3amp Qlite with mine.

If by clay you mean a TIM, I would go with one of artics epoxies, or arctic alumina 5 and 2 screws to clamp it to the pipe.

If you are looking to attach the lens, I think any epoxy will work if you clean the surfaces. Or try sugaru.