I do appreciate all the suggestions, and many of them could be used in other applications.

A pair of rain gutter clamps (for a roof rack) and a good crossbar would work.

Many offroaders/expeditioners will use 2 or 3 gutter clamps per side to hold a roof-top-tent or very heavily loaded roof rack.

Edited to add: Ih8mud and expeditionportal forums both have lots of info on these.

PM sent.

Hello Stewart, and replied! Thanks for your help. ![]()

Some more good news arrived when DIWdiver figured out a way to add a turbo mode to his drivers for 3.38A to each emitter. This should give us just shy of 50,000 combined lumens at the emitters. The drivers are going to need some special attention to heat sinking to be driven at this level, so its going to be a carefully monitored experiment to try and avoid a meltdown. Just how much heat sinking that will be needed is unknown untill everything has been installed and tested. I have been provided great instructions in just where to check for excess heat and where the additional sinks will need to be placed. Whatever is required is what it will get. ![]() Without the drivers, I never would have attempted such a project. After this has all been cobbled together, hopefully others will be able to follow along and build their own “budget” mega light bars for some serious off-road illumination.

Without the drivers, I never would have attempted such a project. After this has all been cobbled together, hopefully others will be able to follow along and build their own “budget” mega light bars for some serious off-road illumination.

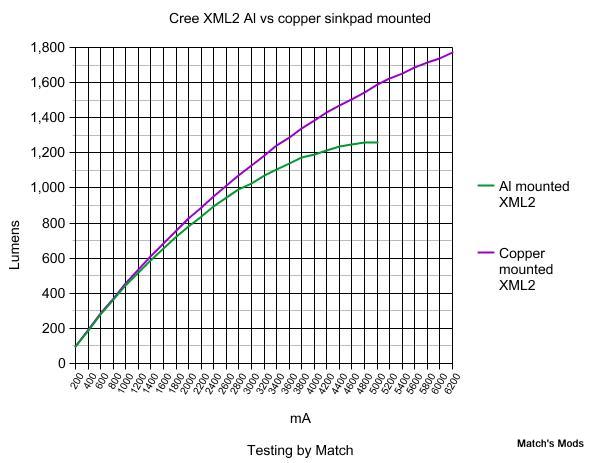

Just playing with some of Match’s figures after extrapolating some rough numbers from these graphs in post 1: Emitter Test Results pt4: XML2, XP-E2, XP-G2, and Nichia219! (along with sinkpad tests)

XM-L2 on copper mcpcb at room temp mounted on massive al sink:

2.7A vF 3.38V = 1050 lumens x 40 = 42000 lumens (Base configuration) Power requirement: .2V (driver) .68V (wire losses) + 13.52V (4 emitters) = 14.40V (2 drivers x 13.5A) 27A x 14.40V = 388.80W

3.0A vF 3.44V = 1125 lumens x 40 = 45000 lumens (7.143 % increase) Power requirement: .2V (driver) .68V (wire losses) + 13.76V (4 emitters) = 14.64V – just for comparison @3.0A at the emitters…

3.4A vF 3.51V = 1240 lumens x 40 = 49600 lumens, (18.095 % increase) Power requirement: .2V (driver) .68V (wire losses) + 14.04V (4 emitters) = 14.92V (2 drivers x 16.9A) 33.8A x 14.92V = 504.296W

In going from 2.7A to 3.4A, there is a difference of 7600 lumens (18.095 % increase) and a 29.9 % increase in watts. It is said that the human eyes need a 20% increase in lumens to notice a change in perceived brightness. It is also noted that emitter surface brightness increases throw, which is often why we overdrive XM-L2 on copper up to 6.5A in thrower flashlight applications. But with the C8 sized reflectors that I will be using, the increase wont be dramatic… only noticeable.

To run at 49600 lumens means that Id have to rework my alternator regulator to put out 14.92V nominal. Thats getting up just a bit too high to risk frying other electrical components on the truck. At 42000 lumens, I can run the stock alternator voltage regulator at 14.4V nominal… so this looks like it will probably be a 42000 lumen light.

What make/model? I've seen higher voltage than that (like when on a battery charger) with no damage.

A better solution in the long run is probably a second, dedicated alternator.

Its an 88 Toyota 4x4 V6 EFI, so not quite new enough to be rated for 15.1V max (as are some newer vehicles). Anything above 15.1V continuous will boil the water out of a new wet cell and kill an older one real fast. Smart charges dont hold a cell at the higher levels during the entire cycle. The truck has the 55 amp stock alternator. Ive ran dual alternators in several of my creations of the past, (like this thing) but Id rather avoid the complexity if possible. Still, its hard to justify 18% more lumens for almost 1/3rd more power. It would also be over-driving the drivers well above their design spec. Ive been warned that if a driver blows and creates a dead short, all my emitters will most likely go up with it.

Yeah the battery wouldn't be happy long-term at 15v, but I'd be amazed if anything else on the truck even noticed.

This will probably be mega-overkill… but for throw beam, I might add a pair of BTU Shockers powered by a third driver. I could drive the emitters at 5 amps each for some decent throw. I need to see how I could adapt a large heat sink to the floor plate of each light before commencing. Maybe remove the driver and add an aluminum bar to the floor plate, and then add a computer heat sink to the end of the aluminum bar. This might need a thread of its own to figure out.

XM-L2 @5A on copper = 1600 lumens x 6 = 9600 lumens of throw beam.

Any updates to this project? I am interesting in building something like this for my father, but maybe scaled down a little bit. He's been wanting a nice light bar for his truck for a long time, lots of nighttime driving on farm roads, etc. Wanted to see if there was any long-term reliability issues with the driver and other components.

Im still waiting on reflectors to arrive before moving forward. I doubt there will be any issues with the drivers, as long as they are used as intended. The circuit shouldn’t be energized unless connected to a load (sufficiant load resistor or LED’s). It isnt protected from a dead short so care must be exercised. The fet requires a large heat sink, and size would depend on the voltage differential and what must be dissipated as heat in watts. The guy who built the drivers stands by his product and has been very instrumental in giving me the confidence to make this total investment. He makes nothing on his sales and puts them together as a meticulous enthusiast to please others.

A lot (if not all) guys are going with TIR optics in their light bar builds, which isnt the best option for a thrower. Although they do throw moderately well when several are combined with overlaying beams, they wont come close to competing with reflectors that properly focuses the emitters. The reflectors greatly complicate the build, but I have a few ideas how to overcome the limitations without needing a precision reflector alignment girdle to index them and hold them in place. I already have a pair of 100W HID wide angle lights that provide plenty of wide area coverage, so the LED’s are only for longer range. Otherwise, the TIR’s would have been sufficient and a whole lot less complex.

Another obstacle might be in rearranging some individual LED’s to balance the vF of the parallel strings once the heat sink warms up. Its going to depend more on the evenness of the temperatures across the sink and taking voltage measurements of each string once the sink heats up. Im hoping that in using this mega 20 pound well designed sink, combined with copper noctigons and all the emitters from the same batch - should help alleviate some of those potential issues. In testing, Ive found that vF can fluctuate greatly with temperature. Another good article from the reef guys takes a lot of the guess work out and provides some innovative solutions: JP's DIY LED Fixture - Reef Central Online Community but this is operating in a static environment… not dynamic with changing air temp and speed passing over the sink. Ideally, the diver would be of a boost design and provide for huge serial strings (75 - 150VDC), but that doesn’t yet exist.

This isnt going to be a quick build. I still need to rearrange my existing aux lights, wiring, relays, switches, mounts, swap in a different alternator for +200 amps @ low RPM; along with the custom brackets, pulleys, fuses and wiring to support it. It will all get done… eventually.

Sounds good, I look forward to hearing your results. I have been playing with a few different TIR lenses due to their smaller size which would make things a bit more compact and easier to mount. There are a couple that throw decently well but none of them are as good as a reflector IMO.

You are right about the emitter vF...as they warm up it gets noticeably lower. If you put an XM-L on a poor heatsink with a weak cell you can watch the amps jump up as the LED gets hot.

Do you really foresee needing to balance emitters in strings? How much variance have you seen? I figure that as long as they're within 0.25A-0.5A of each other I wouldn't worry about it too much at the level you're going to be running them.

There are some decent high-wattage boost converters I've seen on eBay and tested on Youtube, but I worry about reliability vs. this simpler (and well engineered) linear driver. I think that if you had a few of them to spread the load and replaced and upsized the capacitors they may work alright. I may have to get one to try it out, just to see. It would definitely simplify wiring but it may also bring out other issues. I'll probably just end up using this driver.

Where did you get your heatsink? I have bookmarked a few places on eBay and at heatsinkusa.com

I wont know what to expect until I have it up and running, then take several voltage measurements of each string at different temperatures (while wearing welding goggles). :bigsmile: The reef link illustrates what often happens in very meticulously built large arrays that operate in a static environment (which makes them even easier to vF balance). Its a long thread but worth the read. It doesnt take much to wind up with a string that hogs up most of the current.

While individual emitter vF might vary, the greater problem I foresee in this particular type of build is that a fully populated sink typically wont cool 100% evenly across the entire surface of the sink. Since I will be running 5 parallel strings of emitters per driver (4S5P) x 2, there is the potential for some strings to ultimately run at a higher temp, which would create a situation where they keep drawing more current and creating more heat in those locations (which will lower vF even more and cause them to draw even more current and create more heat). Im sure you already know this but thought Id mention it for others. The XM-L2 on copper should withstand a good amount of abuse in a worse case scenario (6A), but Id like to have even output from each emitter string, regardless of the sink temperature. They will be running above 3A each so it narrows the margin for error. After the emitters are in place, I’ll do my best to wire them in such a way that each string shares a symmetrical pattern on the sink from each group of 5 strings. I might interlace them with the other group of 5 from the second driver. Hopefully, that will create an even heat distribution pattern on the sink so they all share the same vF gradient as they heat up and cool down with the varying conditions. At that point, I can vF balance the strings if necessary and be done with it.

While I was trying to vF match my 50 emitters, I became frustrated at how quickly vF lowered directly after power was applied and also how small sink temp changes made a significant impact. After coming across the reef forum, I decided that the best way to test would be after all the emitters were wired to the actual sink and while operating in that environment.

After spewing all of that verbiage… maybe it doesnt matter at all. :bigsmile: Now wouldnt that be nice? But the reef posts indicate that it probably will matter.

Like you, I checked several other drivers and have a good many of them saved in my ebay favorites and other places. While a few of them claimed to be suitable for automotive applications, none of them made mention of voltage spike suppression or thermal management of the driver, or thermal monitoring to throttle power to the device it would be powering. The boost drivers are only rated at the higher amps when they boost only a few volts above vin… which nullifies their advantage for large arrays. Given the low cost differences to power ALL the emitters and the lack of support from the others (and how the Chinese often blatantly lie about their specs), it became clear that there is only one provider capable of delivering such a driver for an array of this size. On top of that, he’s a serious enthusiast that went through a great deal of time and growing pains in developing the driver to make it work as well as it does (check the cpf link in the first post). He also went far out of his way to answer all of my questions to educate me in how to best approach this. Im also engaging in a parallel build project for a landing light array in a custom show plane… so this must be reliable and not endanger the electrical system.

If you find other drivers, please post. Id love to find a cheap boost driver that could efficiently convert 14.5VDC to a stable 36-72VDC @3-4A, not overheat, be reliable, offer voltage spike suppression, driver thermal management and slaved thermal management.

I bought the sink from ebay but it was a one time deal. I prowl often, so If I find another one I’ll let you know.

That makes sense, you could have a positive feedback loop runaway situation. Your interlacing idea sounds like a good yet complex solution. Like you said, it will be hard to tell what really happens until you get it all hooked up and test it. It could be a bigger problem than anticipated or it could end up being much ado about nothing.

His driver is definitely well thought out and understood at least by its seller...the Chinese boost / buck converters are definitely suspect but I wonder if a few additional part tweaks (replace capacitors with higher quality components, etc.) would make them usable. The downside of a boost driver is that if something goes haywire you could end up frying all of the emitters, which would be almost impossible with your setup.

There is a First Person View FPV, RC pilot and whizbang that did a flying searchlight to fly his airplane at night and he worked out some similar problems to what you are facing. There are some big differences along with what he has done but I bet you could incorporate some of his thermal management techniques to protect your rack. He created a driver and a pump for liquid coolant that all fit in the remote control airplane. You should chat him up, I bet the two of you could really make something incredible. Here is the link.

I wonder if you decrease the number of emitters and ramp up the amperage while using active cooling if you might be able to accomplish more with less. Good luck, I hope you get the information that you need.

Thanks for your ideas and link. Although hugeone’s design challenges are quite different from my own, there were great lessons to be learned from his build thread that I might utilize in a future bicycle light. As RMM and I had mentioned, the vF mismatch scenario might or might not materialize. Either way, I can follow the well explained procedure laid out by our fish tank buddies in the other forum to vF balance the strings and get back on track (if necessary). Because of the voltage requirements of the linear driver, Im stuck keeping total vF lower than input voltage if I want to run in regulation. Given what the drivers can provide, watt per lumen efficiency and the size of the sink, 40 emitters in 4S5P x 2 is the ideal scenario. The large rectangular shape of the sink will likely have the largest influence on vF since the emitters in the center could hypothetically run warmer than the ones towards the ends of the sink. But this is just more speculation. Im using a massive overkill sink in combination with a CAD designed emitter placement stencil to precisely locate each mcpcb on the sink and to keep the distribution perfectly symmetrical. Hopefully, this will also result in symmetrical heat distribution… and I think it will.

Flying season has just started, which has been eating up a lot of my illumination play time.

Any updates?

40 xml2’s you’re nuts :bigsmile:

FYI 26.5mm Carclos do throw! Maybe not as good as say a C8 but, they still throw. Here is 24 xml 5000k t5’s, 18 spots, 6 elliptical (4 of my 8” light bars).

Middle dune is around 250 yards. The far one is over 500!

Any updates?

40 xml2’s you’re nuts :bigsmile:

FYI 26.5mm Carclos do throw! Maybe not as good as say a C8 but, they still throw. Here is 24 xml 5000k t5’s, 18 spots, 6 elliptical (4 of my 8” light bars).

Middle dune is around 250 yards. The far one is over 500!

It’s like rolling daylight ![]()

You got your lights working again! Did PTK fix the driver issue or did you have to sub? PM me if you must. I see you’re still running around in that crazed friggin rig of yours, and it apparently hasnt been rolled or blown apart yet. :bigsmile: That is just so bad ass and I love those vids you posted! I just got my vette turning 1.23Gs and finally sticking to the tarmac under WOT, so I feel your LS1 passion when you can keep it running in the power band during most of a run.

Your lights are kicking some major ass, but they are also projecting across a white reflective surface. Still, its very impressive - especially considering the TIR’s. Id never have guessed. I spent a great deal of time researching reflectors, optics, optical efficiencies and radiation patterns for various models. Then I ordered a bunch of samples and took them afield to see how my eyes interpreted each. I already have a pair of 9” reflectored 100W hid cornering lights I converted that pump out 160 degree arc to the sides and 200 yards forward, so I decided to make the LED light bar a pure spot to compliment the existing setup.

Sadly, its shelved at the moment. It turns out that the engineer that designed the drivers figured out a way to slave the thermal throttle controller so both drivers would act as one, which changed my core design. I just havent had time to get back into it.

There is also a parallel project Ive designed for a single driver 16 x XML2 aircraft landing light array for an unlimited category experimental that placed 2nd in national competition. He just wants something that will annihilate the off the shelf lights while saving weight. It will be active cooled with a 1/8” thick copper backbone plate mounted to a CPU sink (8 x XML in each wing with cockpit mounted driver fed via long 18ga leads to each array). Id like to at least get this one up and running (on the bench) first to iron out the bugs because it will be far less complex and not need to be water proof or survive massive G impacts. Lessons learned here will apply to the 40x.

Here’s where I could use some ideas and help:

For the 40x, Im a bit stuck trying to figure out how to mount 40 reflectors in a high G-shock environment without having to machine a retaining girdle to retain, secure and index them. That would cost a fortune to have done. Another member was kind enough to CAD an emitter placement stencil that I can have a shop cut out of vinyl and stick on the sink to allow me to precisely place the emitters and drill the holes for the mcpcb mounting screws. Thats 80 holes to drill and tap. Sheesh! I was thinking about JB welding emitter centering rings to the reflectors. Then gluing flat orings like these to the front of each reflector. Then mounting the large rectangular glass lens in a frame, and using a compression fit of the glass against the 40 reflectors with orings to secure it. I could also probably glue all the reflectors together with JB weld putty from the back side to stabilize it as a solid unit, then the glue mess would be invisible from the front of the unit. Its starting to sound like a redneck project which makes me take a few steps back. There’s plenty of room for error without an indexing girdle and I dont have the orings I linked. I already have all the emitters on copper, drivers, wire, reflectors, copper cut to spec and sinks… so the investment has been made.

ANY ideas would be GREATLY appreciated. Thanks for reading… its late and I tend to ramble when Im tired.

Love the Corvette!

:love: