Thank you. If it’s more efficient then at least there is an improvement, I will keep the XHP70.2 in this light, I like the tint though

I’ll think in unscrewing the glued head and adding some R050 resistors, but not now

Thank you. If it’s more efficient then at least there is an improvement, I will keep the XHP70.2 in this light, I like the tint though

I’ll think in unscrewing the glued head and adding some R050 resistors, but not now

I tried slicing a XHP70.2 dome. Little more silicone came off than what I wanted. Some yellow phosphor came off, and looked like a broken wire. I could only see 1 wire connection, so thinking it was the one extra wire, like the old CREE's have - forgot what it was there for. Looking at the phosphor of the LED, I could not tell any was missing - still solid yellow. The LED lit up ok, but when I cranked it up, started seeing smoke - didn't have the reflector in yet, so I could not tell where the smoke was from. But the MT07, one big light, got pretty warm, I continued with high amps to see where the smoke was coming from. Went too far with it I guess, and a black spot developed about in the middle. I dunno -maybe the slicing, maybe the extreme high amps - didn't measure them, but with a 404 FET, 2S2P of Sam 30Q's, 18 AWG wires, spring bypasses, thinking the amps were wayyy up there.

With no reflector, the tint looks pretty darn good - nice creamy white from a P2 3B.

So any ideas if it was slicing, the broken wire, or the high amps was the cause of smoking the LED?

I tried slicing a XHP70.2 dome. Little more silicone came off than what I wanted. Some yellow phosphor came off, and looked like a broken wire. I could only see 1 wire connection, so thinking it was the one extra wire, like the old CREE’s have - forgot what it was there for. Looking at the phosphor of the LED, I could not tell any was missing - still solid yellow. The LED lit up ok, but when I cranked it up, started seeing smoke - didn’t have the reflector in yet, so I could not tell where the smoke was from. But the MT07, one big light, got pretty warm, I continued with high amps to see where the smoke was coming from. Went too far with it I guess, and a black spot developed about in the middle. I dunno

maybe the slicing, maybe the extreme high ampsdidn’t measure them, but with a 404 FET, 2S2P of Sam 30Q’s, 18 AWG wires, spring bypasses, thinking the amps were wayyy up there.With no reflector, the tint looks pretty darn good - nice creamy white from a P2 3B.

So any ideas if it was slicing, the broken wire, or the high amps was the cause of smoking the LED?

Huh, the 70.2 is a flip chip, wonder where the wire came from? I de-domed a 70.2 and thru a 10X glass I didn’t see any bond wires, just a rocky rough surface of phosphorus? Also what amazed me was how fast the dome fell off during the Hot chemical de-doming, the bond between the dome and chip is super thin compared to the old XHP70 which takes hours to de-dome chemically in my set-up?? Another thing I noticed was how soft the phosphorus was, kind of mushy, flaky? Not like the old XHP70’s phosphorus which is harder and flatter, smoother surface in comparison?

Hhmm, I gotta take a decent pic of it. Dang, thought you chemically dedomed a 70.2, wasn't sure, I searched BLF trying find your pic of it. I just wanted to try some quick hacking to see if I could get some decent throw #'s from the MT07. I "think" Haikelite sent me out an SMO reflector for the MT07 - they asked $15 for it, not bad, so I paid them, just didn't get a shipping confirmation. They said they made 30 of them, but other BLFers who emailed them for it haven't gotten a response from them.

I only saw one wire connection off the square phosphor area, and pretty sure I saw a typical tiny gold wire broken off of it. Think the XM-L2's have that extra wire you could break off - think it was for static protection or something? Was hoping that's what it was on a 70.2.

Edit: We got some low fast moving clouds going by now,and took out the BOSS1, direct drive, dedomed XPL V6, and was able hit the clouds! First time I've done that. Measure throw over 700 kcd with this setup.

Hhmm, I gotta take a decent pic of it. Dang, thought you chemically dedomed a 70.2, wasn’t sure, I searched BLF trying find your pic of it. I just wanted to try some quick hacking to see if I could get some decent throw #’s from the MT07. I “think” Haikelite sent me out an SMO reflector for the MT07 - they asked $15 for it, not bad, so I paid them, just didn’t get a shipping confirmation. They said they made 30 of them, but other BLFers who emailed them for it haven’t gotten a response from them.

I only saw one wire connection off the square phosphor area, and pretty sure I saw a typical tiny gold wire broken off of it. Think the XM-L2’s have that extra wire you could break off - think it was for static protection or something? Was hoping that’s what it was on a 70.2.

Edit: We got some low fast moving clouds going by now,and took out the BOSS1, direct drive, dedomed XPL V6, and was able hit the clouds! First time I’ve done that. Measure throw over 700 kcd with this setup.

Here is a crummy pic… left click, click view image, then click on the 70.2 and you should be able to blow it up a bit?

That is a good deal for that massive reflector, I paid $40.00 for (2) TN42 reflectors and (2) lens from Thrunite.

Ok, I got this freak'n burnt out 70.2 work'n!

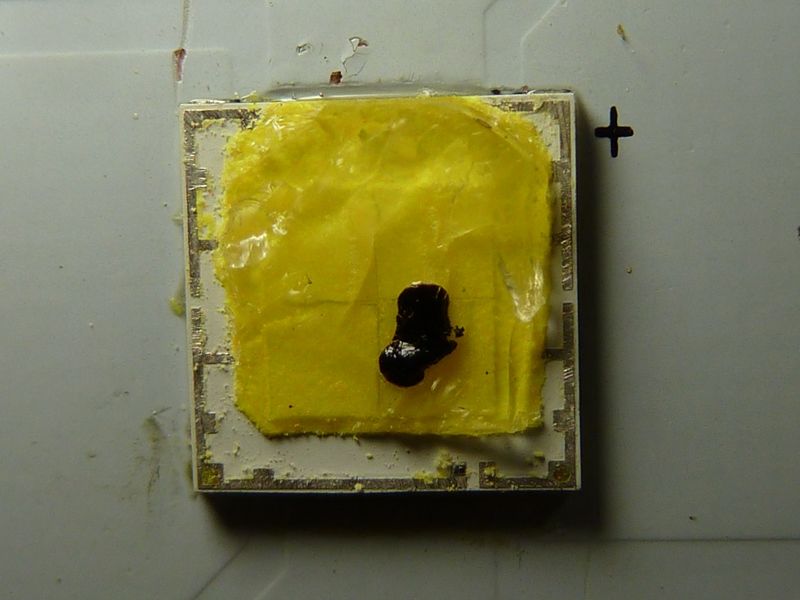

The contact point in the lower right at the edge of the board is what I thought had a wire - not sure now. There's another one on the top as well. So here it is with the burn mark. Weird thing is the black stuff just scraped off - used a very sharp Exacto

Here's the dome, notice some yellow, not much:

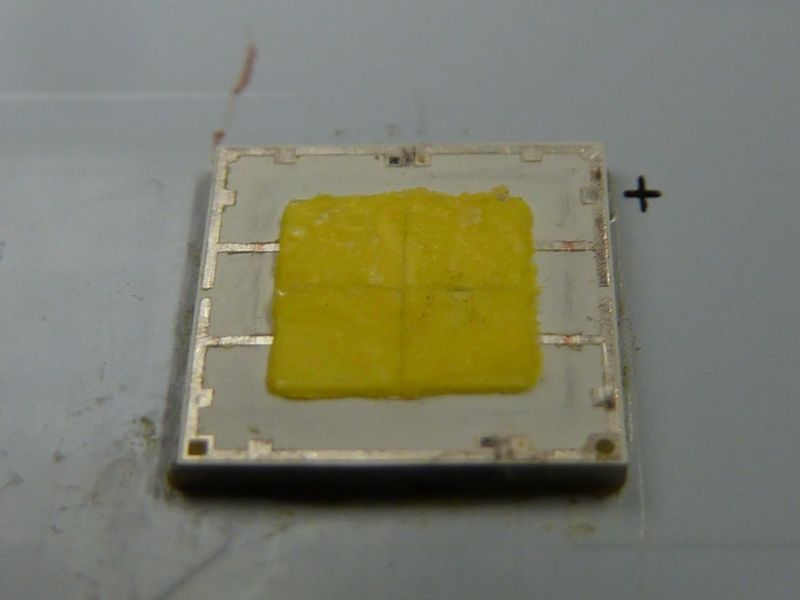

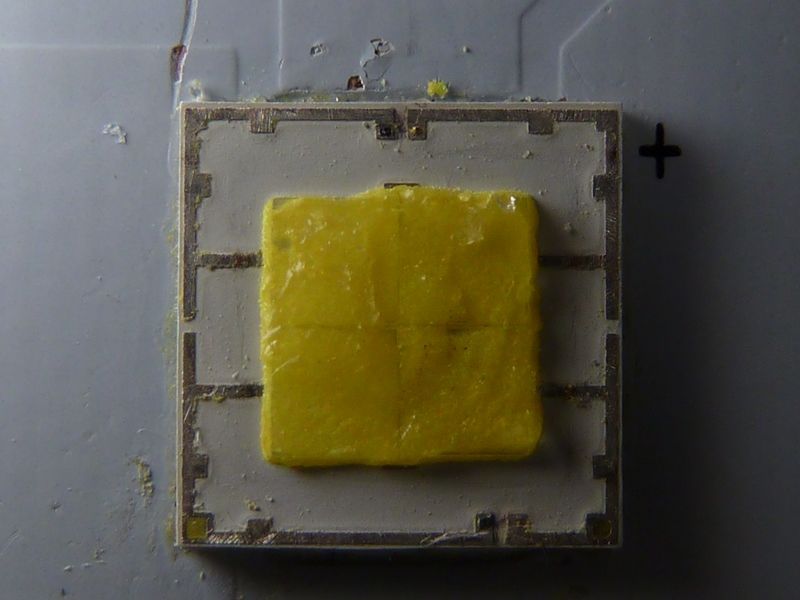

After more scraping, cutting, and the cleanup, really not that bad:

So this abused, misused LED is working, and pretty darn good! Love the tint, love the beam pattern from the OP.

Rough #'s are 296 kcd taken at 5m, and 8,100 lumens in the MT07, with the HQ BLF SRK V3.4 driver, 1 7135, 404 FET.

I made sooo many mistakes with this mod, amazed anything survived, plus weird things happening in some tests, then it all works like it should - I don't get it...

Ohhh - no yellow ring round the hot spot now, nice creamy color - how can so many things go wrong, and come out right?

Dunno why the MT07 isn't more popular - it's built like a tank, very moddable, and they got some good deals goin on it now. freeme has code MTGB for $73. What I really like about it, compared to an L6 or S70S is that there's 4 18650 cells in 2S2P instead of 2 26650's, so you get less resistance, little more capacity. Ok, it's not the slickest look'n light around...

Maybe that burned black stuff was a thin piece of cloth fiber like the ones that are floating around in the air and like to land on reflectors…

Looks good! I was thinking in maybe doing a push cut like Vinh54 does

Maybe that burned black stuff was a thin piece of cloth fiber like the ones that are floating around in the air and like to land on reflectors…

Looks good! I was thinking in maybe doing a push cut like Vinh54 does

this technique inspired the way I plan to shave the xp-g2 for my contest entry and eventually my chimera. Differences: blade brand and use of a shim ring for a more even cut and I’ll be using Polsilver Iridium blades rather than the Derby Extra (I got 5x for a good price)

I like to use a finishing stone afterwards to polish the silicone. I believe a rough surface can cause these burn spots due to local magnification. It looks a lot nicer in a light too. I’m OCD about how the LED/mcpcb looks inside the light.

EDIT: +1 on using a shim. Just make sure the LED is soldered on flat (parallel) to the MCPCB… Ask me how I know :person_facepalming:

Posted this back a few years ago. The shim is set tight to the dome and the LED pad.

Keeping the shim on while I sand the dome flat using a fine paper and then polish with paste.

Only had a couple burn, usually something foreign fell onto the flattened dome, or left over after sanding. They were saved by scraping/ shaving the burnt stuff off. I just had to clean/scrub really well with a high strength alcohol after altering the dome.

KB - you could have just said: been there, done that ![]() . Interesting, so I take it you've moved on from dicing, slicing, sanding by using the chemical method.

. Interesting, so I take it you've moved on from dicing, slicing, sanding by using the chemical method.

I'd say with mine, I've lost roughly - 10% in lumens, maybe added 40-50% in kcd. I don't have a clear before/after though, so hard to be sure. I've hit 9,000 lumens on the same LED in the L6 on full cells, where this was 8,100 on cells slightly under max, ~4.05V or so.

Did you use a sanded down copper penny KawiBoy1428? What is the thickness of the shim? How did you make the center hole? What drill bit size?

KB - you could have just said: been there, done that

. Interesting, so I take it you’ve moved on from dicing, slicing, sanding by using the chemical method.

I’d say with mine, I’ve lost roughly - 10% in lumens, maybe added 40-50% in kcd. I don’t have a clear before/after though, so hard to be sure. I’ve hit 9,000 lumens on the same LED in the L6 on full cells, where this was 8,100 on cells slightly under max, ~4.05V or so.

Not much luck with the Hot Chemical de-dome with the Old XHP70’s, seems the dome is pocketed into the phosphorus, and pad, when the dome released it took some of the phosphorus with it, it was just too fast of a release and didn’t give it time to fully loose itself of the phosphorus, remember MEM said slow and easy, I think he was right.

Did you use a sanded down copper penny KawiBoy1428? What is the thickness of the shim? How did you make the center hole? What drill bit size?

Alex I’ll measure it up when I get home tonight. I’ll send it to you if you want to use it, just promise to send it back when your done K! ![]() :+1:

:+1:

The I.D. measures 6.9mm and the thickness .700mm.

I had another question to those who have ordered LEDs for themselves: is there any way to tell the tint binning of the LEd you’re ordering? All I can tell is the flux bin, but not the tint bin (whether it slots in above or below the BBL)

For example, for a 4000k emitter one there is 5B, 5C, 5A, 5D.

I got a 2step 80cri 3000k XHP70.2 emitter in my L6 currently, but I’m not sure if its tint was worth the lumen tradeoff. It definitely doesn’t seem as nice as the XHP35HI in my Zebralight. (hotspot and corona are a tad greenish compared to spill— spill illluminates my hand as fleshy pink-neutral, while hotspot makes it orangy)

I was thinking getting a higher flux binned 4000k emitter would be nice, but only if I could minimize any green.

Also, do higher flux bins produce more green than lower flux bins?

So what is the verdict on dome slicing these 70.2 emitters? Is the beam ok? What does it do to the color etc?

is the P2 3B the highest bin for this led in 5000k?

is the P2 3B the highest bin for this led in 5000k?

Yes P2 is currently the highest.

Please send code for NW Thanks