Some details of my current modded Z1 done last year are here: https://budgetlightforum.com/t/-/28881/43. It does 216 kcd with a de-domed XM-L2 U4 1C, stock driver resistor modded.

It would be interesting to find out how a XHP35 HI in a Z1 compares in throw. There's been quite a few modded Z1's posted, some with MT-G2, etc.

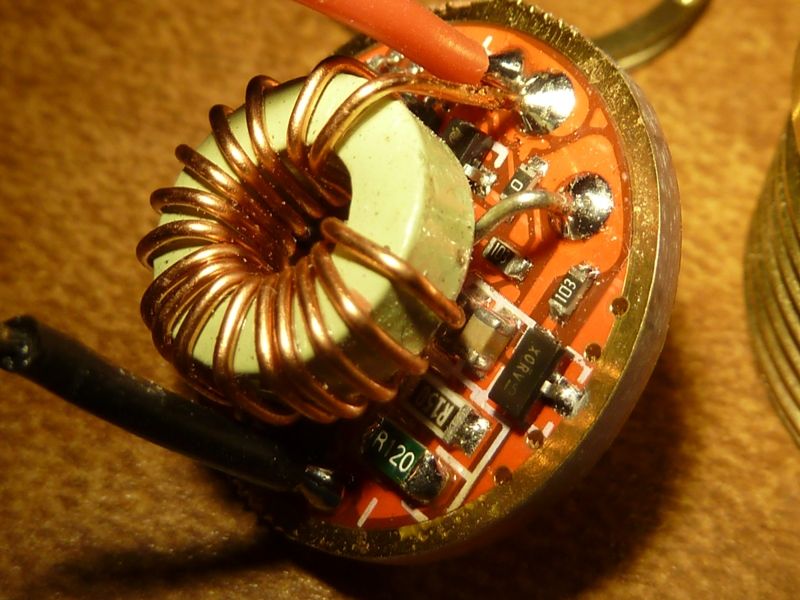

R120 shown:

Got the wires very low: