Of various hobbies that I’ve had, home audio was my first major and sustaining past-time.

I started reading and learning about home audio in the early 1990’s from periodicals such as Stereo Review, Audio and later, Sound&Vision and Home Theater. With the the purchase of a Yorx sound system that came with some nice full frequency speakers, I started swapping transducers and eventually began my hobby of building speaker enclosures. The first ‘sub’ was made from a 5 gallon paint bucket and a 6.5” Redline driver along with full range RadioShack drivers installed in the satellites constructed of oak laminate particle board. I had decided the best bang for the buck was a subwoofer/satellite speaker system.

By the mid 1990’s, I designed and built a dual mid-bass satellite enclosure that really looked nice but the pair was never realized. Around this time, I found suppliers for high quality woofers, tweeters, capacitors, inductors and resistor components. Component brands that were used in ready-made, mid to high-end speaker systems such as Audax, Vifa and Morel were available and inexpensive. Inspired by some of the designs I read about in the periodicals, I designed and built a new pair of satellite speakers.

The new pair took some planning and coordination. I needed a router for the baffle and fortunately, a high school friend’s dad had an awesome workshop. The Audax tweeters and Vifa mid-basses were ordered and I even designed my own 2nd order tweeter crossovers. I had experience with burning out tweeters on commercial speakers so I wanted a steeper roll-off to protect these at their designated low end. Of course, what bookshelf speaker would be complete without a matching set of stands? I made those, too!

I certainly heard a better quality of sound, neutral in the mids and spacious in the highs! I was quite proud of them and even made side-by-side comparisons to similar sized models at a few specialty stores in town. Paradigm Atoms were one of the comparisons that I recall making.

In 2003, I developed a new design (really to match my satellites) and decided to build the new system around an Infinity Kappa Perfect 12.1, DVC subwoofer. The driver has an aluminum cone, butyl rubber surround, a cast metal frame, a vented voice coil and rated to play down to 20 Hz at audible levels. Substantial! The enclosure is principally a 16” diameter PVC pipe with an internal structure affixed to mount the heavy transducer. The following photos demonstrate the construction:

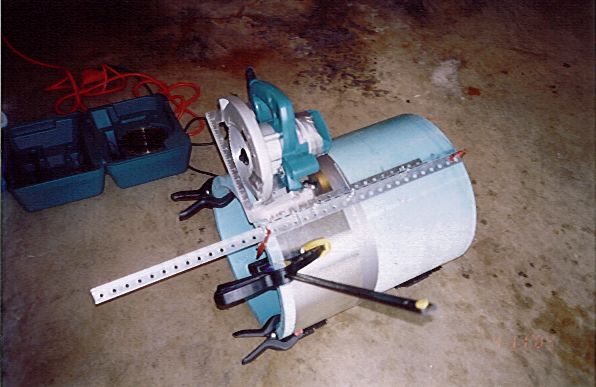

With fairly basic tools, I needed to cut as precisely as possible. I created a plunge cut jig for the thick and heavy enclosure material.

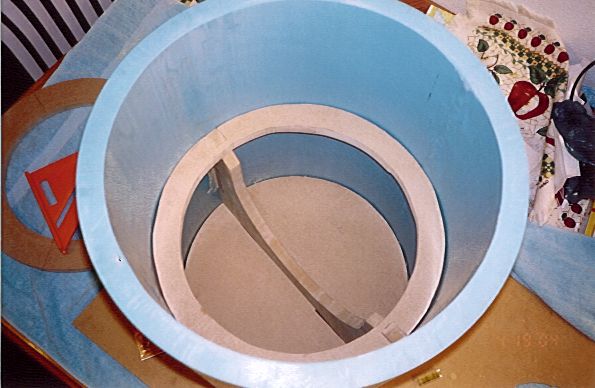

The next step was to affix an internal end cap that would serve as the ‘foundation’ for the substructure. The next part resembles a brace, typical of box designs to eliminate panel vibration, but in fact, it is a spacer. This spacer is inserted in the end cap and held in place with Liquid Nails.

The next integral part is used to mount the speaker baffle assembly and is held in place with Liquid Nails.

The baffle, below, is the board that a speaker is mounted to and I originally was going to orient the driver with the magnet inside the enclosure. That presented a few challenges such as cable routing, driver access, installation, etc.

The baffle and speaker is more of an assembly that is then bolted to the inner structure.

With this design, the wires and driver are out of sight as well as protected from dust settling into the ‘motor’ so a reversed orientation works well. Also, I find the interesting part of this woofer to be the magnet and frame and, why hide those nice banana terminals?

Considering the weight of this sub woofer system, 90 plus pounds, a stand needed to be substantial, sonically enhancing and aesthetically appealing. The whole speaker rests on ‘donuts’ attached to a ring that fits to the inner diameter of the pipe.

Two pine rounds are a perfect fit for the top and bottom, the system being oriented bottom-up in photo below. No matter what surface I place the sub on, carpet or floor, the gap is consistent and the sound flows into the room without being absorbed. I bought some carpet spikes but it is easier to move this behemoth without them.

The final product,