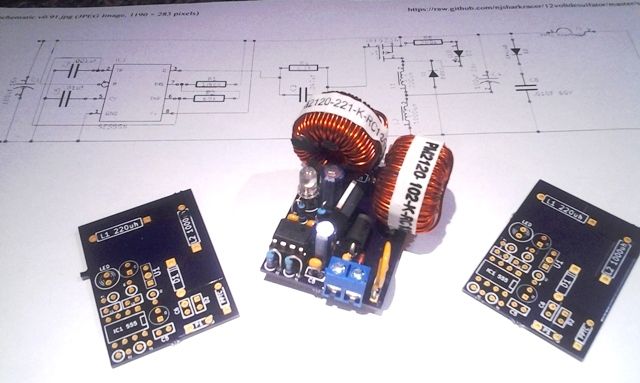

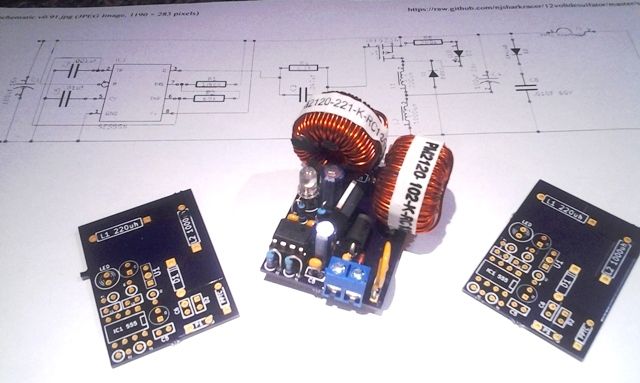

Well..finally got the stuff in from Newark, build me a 12vdc desulfator

Project info and links here

https://oshpark.com/shared_projects/ATrDSRDV

Be sure to watch the guys youtube video's

Well..finally got the stuff in from Newark, build me a 12vdc desulfator

Project info and links here

https://oshpark.com/shared_projects/ATrDSRDV

Be sure to watch the guys youtube video's

Might be a rude question, but do any of these battery life extenders actually extend battery life generally, or only in limited circumstances, if at all? Just that Ive seen so many things to help batteries like treatments at sale to double warranty, tried once, seemed to do squat. I get that build up on the plates would kill a battery, but is it a certainty that your battery will be infected with this type of build up without the device?

Yes

This desulfator is more or less a brute force method, they are developing other things to combat sulfation (since lead acid batteries aren't going away any time soon), so either wait for them to develop them...I have one in my hand...yeah...it's a "dumb" method but it has been proven to work and work well (for the application intended, sure could there be better...absolutely)...in fact you can buy many of these units commercially at 10-20x what I built mine for

Either or, I did it because I wanted one, and to teach my kids electronics and soldering..

My boss at work has a 4 wheeler with a sulfated battery (sat for a year w/o running), will build the other ones this weekend, get a lead and battery clips, and see if they do work or not (of which I know they work, used to have one on my truck, it only ran when the truck was running, desulfated for 1 hr each way every day in my commute to work...for 5 years the battery held it's charge like the day it was new...only problem the $50 sulfator got hot and ended up melting...this one uses a slight current to run so a trickle charger is needed to prevent draining the battery

Heck you can build one on perfboard w/o the PCB if you like

And not rude at all..how else are you going to learn if you don't ask

Might be a climate thing, but I get 5 yrs without doohickeys on my daily driver. Probably helps that I buy decent batteries to start with, not the cheapest (not suggesting you dont, or do). I have seen so many things that make claims of ‘saving you in the long run etc’, but none seem to work. Be good to see something that does. Im not saying they no effect at all, Im saying that batteries dont seem to last longer than not using them.

Be interesting to hear it does actually extend battery life. How much parasitic drain is it? Would you use it on a daily driver and just run it off the battery too?

How much did it cost to build this?

Your design will cost $11.70 per set of three.

Bill Of Material

Mdse Total $33.58

Sales Tax $3.51

Freight $9.26

-----------------

$46.35

$11.70+$46.35 / 3 = $19.35 a piece

Sitting with my kid soldering stuff on a board, getting him psyched about electronics and spending quality time together...

I have been wondering about these for quite some time.

I was at a dedicated shop that delt with servicing batteries and they had developed a business based on repairing batteries. They had about 30 chargers going while I was there and each had a BUILT IN Desulfator! They were a commercial version of the popular “Vector” brand of battery chargers. I made a note of the model number and thought I was all set. Later when I went on the Internet, I could find nothing on it.

Later I will post my notes, maybe someone else can find more info. I would buy one.

Also, many heavy users of lead acid batteries use Desulfators routinely for golf carts etc.

Yeah, this would be the poormans version of the above battery restore charger, I bought a battery minder (that is the one that fried)

With this you would need to include a trickle charger as the unit itself uses about 300mA to run, with no charge going into the battery, it would drain it down

This is a video from the guy that made this board, he has 9 video's explaining what he did, it shows after 30 days the sufation on the battery almost competely down

He says on average 1lb a day, so you have a big ole honkering battery it WILL take some time

In my experience with trying to restore lead acid batteries (mostly automotive) it depends on how well the battery is made and what it was subjected to before you start trying to hook up a defibrillator. Its my understanding the battery desulfator breaks down the build up of sulfation between the lead plates that can cause a dead short or a weak battery. It does nothing for the lead sulfation build up at the bottom of the battery case. When the sulfation build up reaches the bottom of the lead plates, I have had no luck reviving a lead acid battery that has this condition. I have tried flushing and cleaning with caustic soda and installing new acid along with the desulfator. A few batteries did show improvements with cleaning and new acid, but they did not last long enough afterwards to make it worth the effort. The desulfator did let a few batteries live longer, with the greatest one being about 6 months. It was fun playing with all this dangerous chemical stuff, but after I thought about all this a little while, For the cost of the desulfator, chemicals and new acid, plus all the time spent, I could have purchased a new battery, which I had to do shortly after all this anyways. So if someone figures out a way to get a few years or maybe even a year of extra life out of a shorted or dead battery, maybe I might jump back in, but for now its a new battery for me. With a battery that’s still good but showing signs of sulfation, it could be a very different story as a preventive measure.

I’m convinced if you ran the desulfator to clean up between the plates, then pull the top off the battery with the lead plates and installed the top in a new case, add new acid, seal up the case, you could get several more years of battery life. Maybe even to the original specs. A lead acid battery is just that, lead and acid.

This is just my 2 cents. ![]()

.

Let us know how this turns out for you.

YUASA makes a motorcycle battery that was always my go-to. For this size battery they are warranted about 90 days typically. I had YUASA’s last 3 years or more. They are built with a patented sulfate stop. I put over 50,000 miles on my V45 Sabre and it was always on a YUASA battery.

And for the record, if you’re not going to use your machine for a year, pull the battery or sell the machine.

Ive got one car I dont drive that often, but i dont believe in not startng them. I run it once a week, to once a month. I leave the battery in it, but its on a charger maintainer. It will allow the batt to drop to around 12.4v, then charges it again to around 13.8, shuts off until it drops again. Been good so far. I say around because I dont have the paperwork handy, and Im pretty sure thats what it is.

Would I ever build such a thing - hardly!

My wife's Fiesta would not turn over a fourtnight ago, it was -5degr. Celsius.

That was the first time it had problems with the battery. It is a 1997 model with original Ford battery and has its place in the open all the year in the medium cold climate of Denmark.

15 minutes with a charger once, and it started again, and still does.

Now, for the last of the cars life, I will monitor if the battery's voltage goes under 12.6V and then put on the charger for a while.

I guess there's a bit of luck involved in this huge lifespan of 17 years.

You’re surely doing something right! 17 years is incredibly long for a car battery to last.

Hmm. My dad had a Citroen ZX that kept the original battery in it for the 10 years he had it. And he bought it when it was 4 years old. But he is also in Denmark. Maybe the climate helps actually?

Thanks for the info, very cool. Great thread.

As I mentioned in a previous post, a battery shop I was in had about 30 of these Vector Smart Chargers with built in DeSulfators. It seems Black and Decker bought Vector so now all the chargers are branded B+D. Here is a YouTube video of a B+D charger and 1:31 into the video you can see the word “DeSulfate” under the “Battery Recond” button. More recent versions do not include the word DeSulfate.

Here is a PDF of the manual. http://servicenet.blackanddecker.com/documents/English/Instruction%20Manual/Vector/VEC1089ABD.pdf

I'd like to build one of these. I have a couple lead batteries that I'd like to get more use out of. At some point I may just keep a few of them for emergency charging power instead of a bunch of lithium ion cells. Then I'd keep most of my lithium ion cells at long term storage voltage and charge them with the lead batteries if they're needed in an emergency.

I didn't know about sulfate protection. That helps justify the price. I need to get one of those for my bike, plus an on-bike trickle charger. A trickle charger shouldn't be necessary, but I've been burned too many times by a low battery. It costs more, but it'll be totally worth it if the convenience of easily topping off the battery once a week prevents a surprise dead battery.

I tested the first build with my kid tonight (AFTER I flipped the electrolytic capacitors around...seems after two decades I forgot the "standards" of PCB marking and the square solder position is for the positive side of the electrolytic cap....DOH) well all in all it runs and didn't let out the blue smoke, could hear a high pitch whine and the LED lit up, and none of the components ran hot

So...me and the kiddo sat down and put the other two boards together...will be testing them soon, this time when we put them together we did it when noone else was awake to bother us (last time I put it together my wife interrupted the train by cooking dinner and asking me to help...yadda yadda so I got frustrated trying to hurry and whatnot) even let my son solder in the LED's on the board, and he didn't do too bad considering it was his first time ever.

I picked up some 18GA wire and battery clips and a few odds and ends, got a project box from RadioShack and a replacement 1Mohm resistor, I broke the leads on one, then desoldered the LED from the board, drilled holes for the LED in the lid, ran some thin connector wire from the original location on the board to the leads on the LED on the outside of the lid so you can see it light up and know it's running, epoxied board into the box...ready to go

My boss at work is going to do a full test on it, has a heavily sulfated battery and will see if it works

Been a really long time since I futzed around with electronic fundamentals...downloaded an android app that helps called ElectroDroid, it helps!

YOINK!!

Thankyou, looks alright. Ive forgotten what the coloured stripe values were on resistors, as soon as I saw them, yoink.

Its always good to do things with the kids. Tried to put together an electronic robot thingy, never worked, maybve it was us, maybe it was a dud but I didnt try that one again. We did successfully build a Tamiya RC car which was fun. More my speed putting gears in, building suspension etc. In the end its all we leave of any real value, memories. ![]()

I’ve had a Battery Minder 12248 for a few years. Using it, I’ve tried to revive 2 pairs of 12V SLAs used by my APC 1500 UPSes. Each battery pair was still considered “good” by the UPSes but the reserve runtimes were substantially lower than they were when the batteries were new. Each pair spent at least a week on the trickle/desulfation cycle (on a whim, I left the second pair plugged-in for at least a month maybe 6 weeks). Neither pair of batteries showed any improvement in runtime afterwards. Disappointing.

Now, it’s possible that my batteries weren’t sulfated and the decreased runtime was due to deterioration of the plates themselves. Or it’s possible that at some point the UPSes overcharged the batteries and caused bubbles to form in the gel around the plates. I’ve tested the charging circuits, though, and if anything their trickle voltages are slightly low so I’m not sold on the latter possibility.

In my limited experience, I’m not convinced that desulfation circuits make any difference.