You know you want to ![]()

I had mine custom-made by Sofirn, as reflowing emitters onto MCPCBs is something I’ve never done, and I know I’d probably screw it up!

You know you want to ![]()

I had mine custom-made by Sofirn, as reflowing emitters onto MCPCBs is something I’ve never done, and I know I’d probably screw it up!

I had mine custom-made by Sofirn, as reflowing emitters onto MCPCBs is something I’ve never done, and I know I’d probably screw it up!

Believe me - it’s the easiest part of the mod.

Allthough … I did it wrong and had to reverse the polarity. Not for the first time I got this wrong :person_facepalming: .

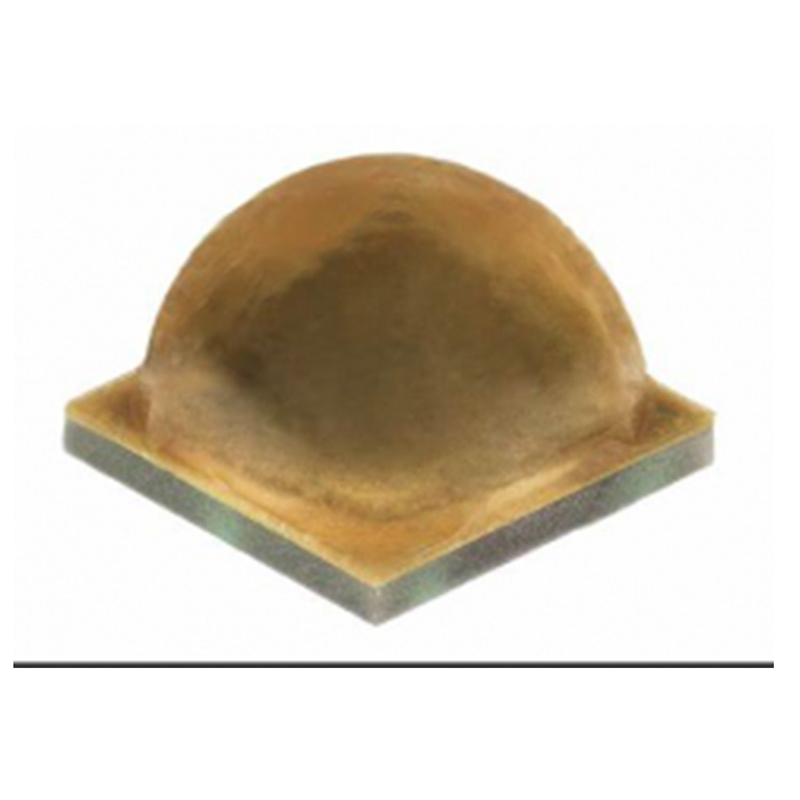

Sofirn has some stock of the 5000K XHP50.2 at $4.99 each:

sofirn

sofirn

This is a bare LED, it will need to be flowed onto an MCPCB before it can be used! XHP50.2(3V) has two tints options6500K (1C 1D)5000K (3A 3B)

Price: USD 5.99

I’ve odered two boards from LED4Power, so I’ll populate the 2nd one with the Crees.

The Q8 with SFT40’s would be the next sensible version, 8000 lumen with significant throw.

It’s unfortunate that Sofirn no longer offers the Q8 & the drivers in host form. Would have populated with various emitters.

@Djozz: I second that. Although the XHP50s have much punch, their light quality is less than ideal at lower modes. The SFT40 I have doesn’t have such aberrations and does much better throw.

And then I checked the beam of the XPL2s and my Q8 isn’t bad at all – enough to maybe keep as such.

I have the Sofirn Q8 with XP-L Hi in it - too much throw for my taste, in my world, sodacan lights should be floodier than everything else.

If the price is in the rough range mentioned in first post ($22), I’m in.

Any info about the FET swap? Which FET should be soldered in?

The emitters are $5 each. No need to change the FET (Tom suggested better efficiency ones, but they aren’t a must) and the boards, well I don’t know if Led4Power still has some.

You in luck Led4Power

I agree the SFT40 would be nice, but I’m waiting for lower CCTs.

If the price is in the rough range mentioned in first post ($22), I’m in.

Nah, board plus LEDs will be more. You need to consider VAT in Germany.

Alright, just ordered a couple of things vom led4power, thanks!

I will use two 5000K and two 5300-5700K XHP30.2 3V from Sofirn.

Have fun modding the Q8 ![]()

You will need to ‘ream’ the reflector holes and add some 5050 gaskets. If memory serves, 7mm holes or whatever gasket profile you may have. Also, a retaining piece for the MCPCB. Djozz had a piece of flat aluminium within the driver cavity and used a 6mm screw through a hole of the said bar to pull down the Led4Power MCPCB. Others just omitted this and with the bezel against the reflector, held everything in place.

But what am I to know, not having done the mod but thru these posts. There is another thread also (previous to this one) in the modding. I’ll have to dig thru that one for some reference shots of Djozz solution.

You mean this thread:

Ok, I hacked something together. I figured a washer would require making extra holes for the wires anyway, so I made it a piece of aluminium 35×10×3mm with a 4mm hole in the middle, well, not really in the middle, it was a quick hack[image] The screw is M4, and from the back of the shelf to decently screwed in the hole in the reflector (there is a bit more than 3mm deep working threading in the reflector so you have some play) you need 16mm of threading (so the threaded part needs …

No Problem, I have a lathe and 3 3D Printers, I will find a solution.

I have these washers since like 10 years laying around, I knew that I will use them somedays - validation that hoarding stuff is good. Sometimes.

I ordered the LEDs, MCPCB and I have the light already here, now the waiting game begins…

Yeah, that’s the one. Good you’re on top of the challenge. Printing such spacers won’t be much, I suppose you’ll use some heat-resistant fill?

I would make them (gaskets) as the need arose. Simple matching of some round stock. Just recently splurged and bought every type from Convoy. To simplify the construction of some lights.

Hoarding? Nah! I call it preparedness. Keep many such things and at times am glad I did as last-minute purchases cuts the enthusiasm.

Also, a retaining piece for the MCPCB. Djozz had a piece of flat aluminium within the driver cavity and used a 6mm screw through a hole of the said bar to pull down the Led4Power MCPCB. Others just omitted this and with the bezel against the reflector, held everything in place.

I just drilled two 2.5mm holes in the new MCPCB.

Both MCPCBs back on back, M3 Bolts through the two cable-holes to lock it in place and then you can mark the position of the two holes with the tip of a tweezer or something else very sharp.

If you don’t get the position correct, that’s no problem since these holes are non-crucial, there are just the two bolts which secure the MCPCB&Reflector package into the host going through into the reflector.

Hotspot is now 5x as big. Still throwy in comparison to the two modded lights with those triple-Boards from Kaidomain and the small reflectors, but much more usable for me.

OK, let’s see if I got this right:

Made 2 new holes for securing the MCPCB to the shelf. Used the original board as a template for these new holes. So drilled thru the traces – what do you do about isolating from electrical contact via the screws? Perhaps some TO-220 bushings? Or Kapton wrap of the screws (be it a slither of width).

Do you secure the reflector via the large center screw (IIRC 6mm)? or rely on the bezel to hold the whole thing together?

I haven’t opened my Q8 for a while *, so some of the details are fuzzy. But I can see that set-up working. Don’t think a bit of trace width reduction will impart a bottleneck in current; I believe they’re overdesigned in width and thickness.

As for the throw, sheer brute lumens. What I call a “blaster”. A larger hotspot is good for wider illumination. I’ve been using my Q8 as a worklight when doing general renovations. Mounted on a tripod it does ok, in as long I don’t back into it (which has happened once).

* I was going to mod my Q8 also but the 3 Volt XHP50s were out of stock, and then when they got re-distributed, they were only 6500ºK. Just last month I ordered some 5000ºK, but they haven’t shown up yet. Had taken a break in this hobby – getting somewhat expensive and too many items don’t fit well. Got back on the horse, sort of speak. Just looking over some of my older lights and they need a refresh. Like a Sofirn SC31 w/ XPG3. Many things are in the works, but the post is the procrastinator (Canada Post - lost all tracking of 3 different shipments).

The holes are drilled through the negative pole, so it won’t hurt if it makes electrical contact to the screws

I used all the screws as in the original design, the center one is an M4 screw.

Drivers drive via the negative terminal. Have a look at any one and you’ll see the positive (battery top) go thru directly to the LED. The negative (battery bottom) is the one picked up by the outer trace and modulated and then out to the LED negative.

I can only assume the MCPCB mask is isolating the path, else you wouldn’t have any switch control (the light would just be directly driven). You made a clean hole though, with no burrs to contact the thermal copper plate and thus short the circuit (if the head isn’t isolated from the body).

I don’t see an advantage of screwing the MCPCB down except peace of mind. My Q8 body seems to not have problems heating up fast.

Quite right about holding down the MCPCB. Many of my lights have no such, bezel holds down everything. Centering (no skewing of the reflector) becomes much easier.

As of the same matter, some of my lights don’t require a retaining ring on the driver. Too small or needed the cavity space (spacer added).