RMM is on the money here. I am no guru on this subject, so I don’t want to be hasty in pointing this out, but the thing is advertised as a 4A controller. When that happens, based on my limited knowledge, 4A is what you can do with it in a best case scenario. In the case of a buck controller “best case” is usually close to the the maximum output voltage and an input voltage that’s just enough higher to get it in regulation. The point is that running a relatively low output voltage (3-8v) and a 1.5x+ input voltage just isn’t going to be the ideal scenario for this chip. It’s not specced for that. This is rarely made entirely obvious in the datasheet, but I think ST was maybe even a little worse than usual about it with this product.

FWIW we still haven’t proven that the LED2001 dies when run w/out heatsinking with an MT-G2. All the ones that have been killed so far have either been by accident or while hooked up to the lower voltage XM-series emitters. I don’t understand the topic well enough to know exactly what would cause them to fail. Mattaus did test v1 on the bench with an MT-G2 and that did not fail.

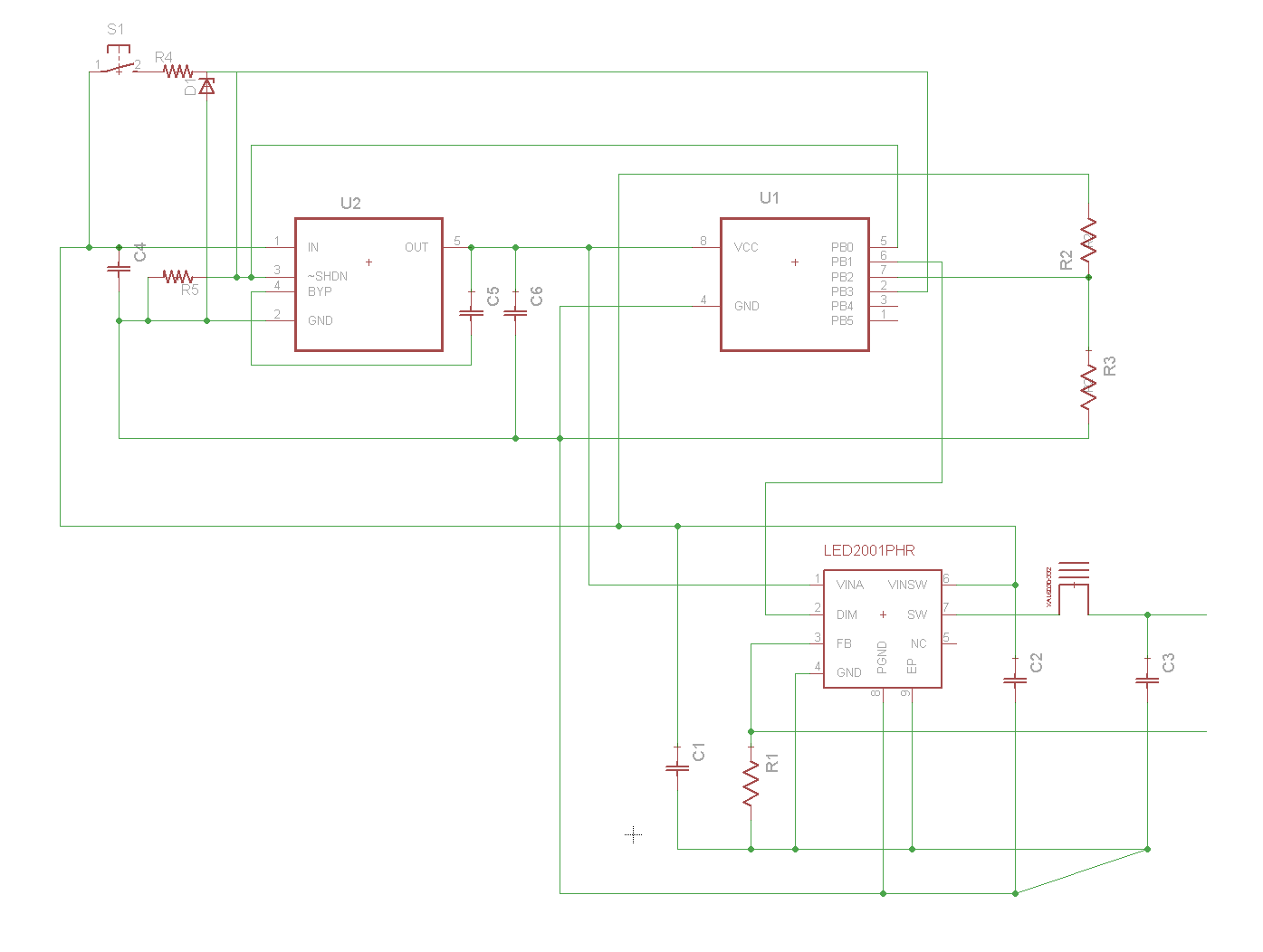

I arrived at the same place you are at RMM. I think looking at a driver which allows an external FET may be the way to go. I was also thinking of trying to build a simple current controlled buck driver like this one in order to get a better handle on the subject. He is just using a comparator for the actual buck circuit with another comparator to get the PWM in there. I don’t know about the sensing setup he’s got there though. I haven’t pieced together whether it could be adapted to something more suitable for high-power or whether that would call for a whole different setup. In any case it sounds like a simple design like that will not have good efficiency compared to a proper controller.