I am working on compact throwers using LEP modules from bl-light.com

These modules have integrated Lasers, Phosphors, and Optics that work together to produce white light. The modules can basically be treated as a weirdly shaped LED with a narrow emission angle. Just like an LED, you will need to find a way to drive it and have a condensing optic to focus the light.

Based on my tests, this company makes quality phosphors that are much better than silicone based phosphors that are used on top of LEDs. I believe the phosphor they make are sintered ceramic.

If you have questions or purchasing, feel free to contact TED. He is very helpful:

ted@flamingoo-light.com

–

The modules I am interested in integrating are: NR2, NR8, and P20

NR2:

1900 cd/mm²

1800 lumens

50 watts (16V @ 3A)

NR8:

2000 cd/mm²

4900 lumens

100 watts (32V @ 3A)

P20:

1260 cd/mm²

11000 lumens

250 watts (82V @ 3A)

NR2 / NR8 development:

These modules are nearly the same size and can be interchanged with small modifications to the host.

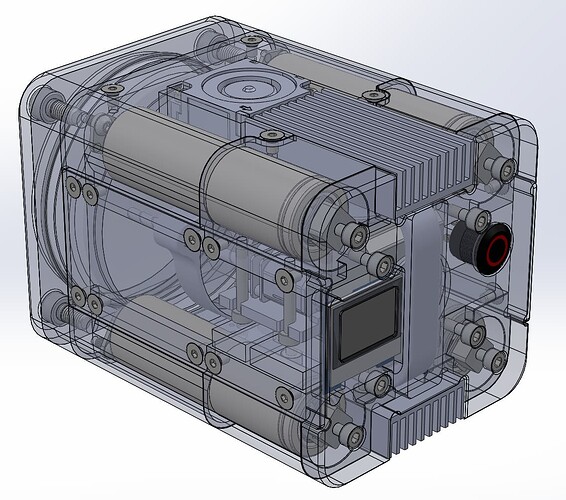

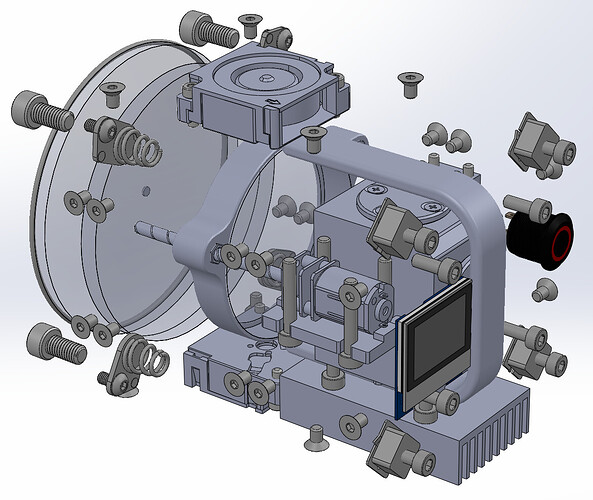

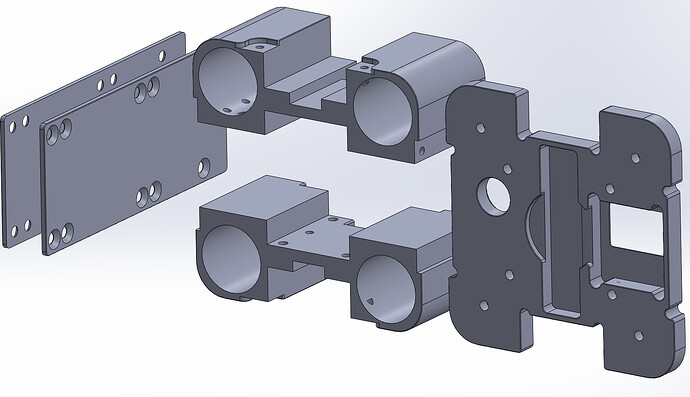

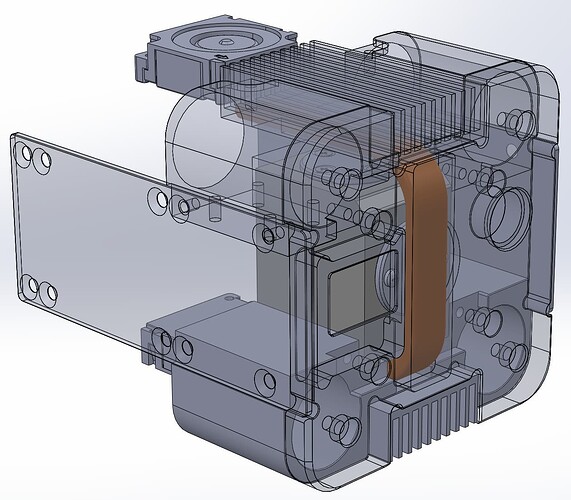

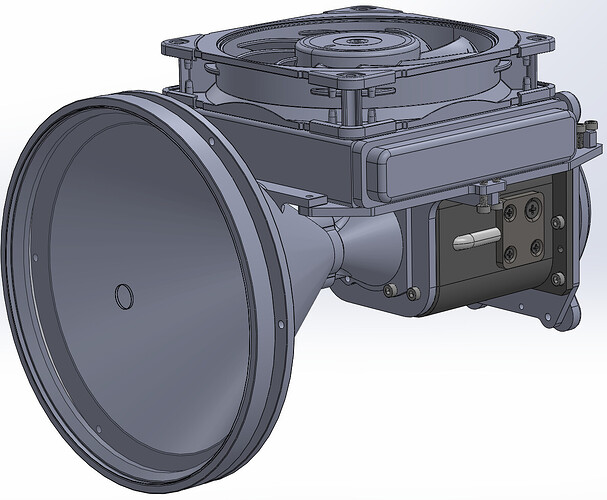

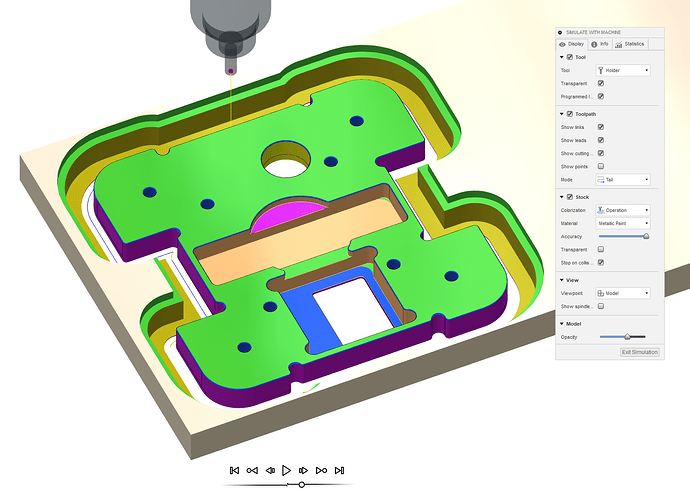

I am working on a prototype host that is flexible in design and using only the minimum amount of CNC machined components.

This host has the following specs for the NR2:

Dimensions: 82 x 82 x 117mm / 3.23 x 3.23 x 4.6 inches

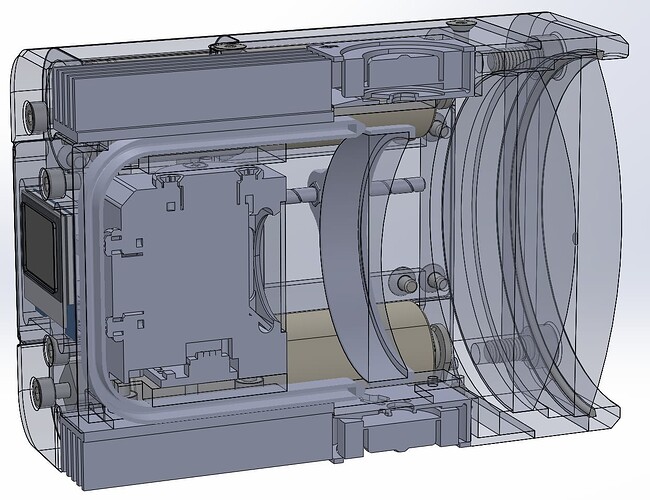

Optics: 75mm PCX, 70mm PCX, 50mm PCV. The 50mm lens actuates 30mm.

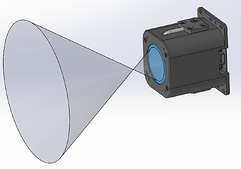

Throw: 8 million candela / 5600 meters. Flood beam is 40° angle.

Battery: 4x 21700, interchangeable

Run time: 70 minutes at max output

Cost breakdown for MOQ 500pcs in USD:

NR2 module: can not disclose

laser diode array, Nichia NUBB23 - 41

3 lens set: 60

CNC machined components: 43

battery 4x 5000mah 21700 cells: 11

laser driver: 12

electronics: 9

fans: 8

heatsinks: 7

mini OLED: 6

optic actuator components: 6

3D printed components: 5

fasteners: 5

heat pipe: 4

TOTAL: 217USD, excluding NR2 module and assembly

I’m wondering if there are vendors in China that may be interested to sell some when prototype is more mature. Everything will be sorted out for them. They would just need to be willing to stock inventory and build them. The price would probably end up being 500USD. They can keep all profits.

Not sure how the law and trade restrictions would work for this. For reference, I had no issues buying samples of laser diode arrays ranging from 20 ~ 110W laser light output shipped to USA. If shipped functional, I might need to integrate an interlock system to disable the light when any part of the enclosure is removed.

Potential to further reduce unit costs:

Laser module:

I am hoping to coordinate with bl-light to redesign their module so that it is 100% integrated for this host only. This would GREATLY reduce costs, assembly complexity, and increase thermal performance.

Lens: 60 > 21USD

It is viable to use fresnel lenses to reduce cost. They can be made with an ASPHERIC profile!

For example: NTKJ

Additionally, they can be AR coated, which will bring the transmission efficiency to 95% for a consumer grade quality. For reference, an AR coated glass optic has a 98.5% transmission.

Mold cost for PMMA fresnel concave lens: 2400

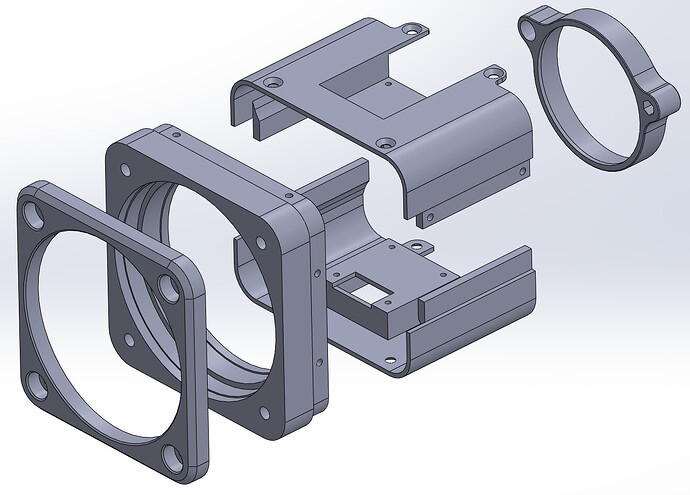

CNC machined parts: 48 > 22USD

Aluminum extrusions are well suited for a design like this. Aluminum casted parts may also work well. For aluminum extrusion, the thermal performance may slightly improve as there will be a little bit more aluminum surface area for the heat to spread instead of plastic.

Mold cost for AL extrusion: 1300

Mold cost for AL casting: 6000

Plastic injection molded parts:

By using “PA6 30GF” (Nylon + 30% Glass Fibers), parts can be extremely durable and abrasion resistant. This is the material they use on power tool shells. Definitely more tough than aluminum.

Mold cost for plastic IM: 6000 (with a few sliders and lifters)

Unit cost per part: 0.75USD

This current design is focused on flexibility, so there is a screw for everything. A version intended for mass production would have a reduction in the usage of screws.

If I were to implement all these changes and without factoring in mold costs, there is a good possibility to bring reduce the unit cost by 80USD.

Making the TOTAL: 137 USD, excluding NR2 module and assembly

Current Progress:

Driver:

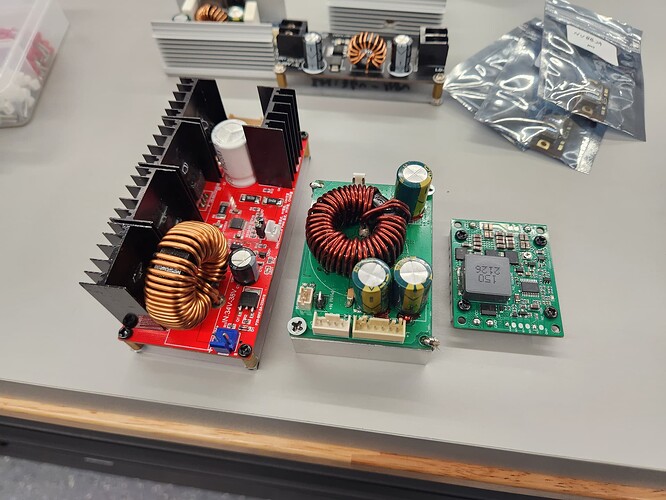

The biggest bottleneck and struggle for me right now is designing a compact laser driver that is also cheap. I have two contractors working on this, but the results are slow.

Examples of compact drivers:

https://www.taskled.com/techuboost.shtml

https://www.loneoceans.com/labs/gxb17/

These are using high grade boost converters and inductors.

If anyone is familiar with LED/Laser drivers, DC-DC converters, I am offering 85USD/hr for design/prototype services.

MCU to control:

- laser driver output

- temperature monitoring (laser diode array and driver)

- OLED screen display data

- lens actuating motor controller

- fans speed

- interlock (If any panels are removed, the laser will not function. Comply with laser safety)

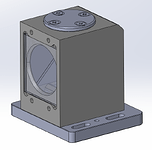

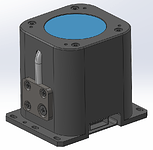

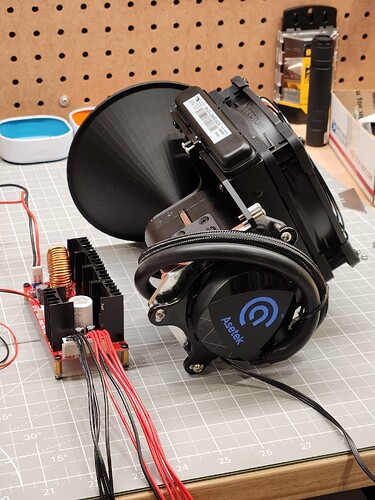

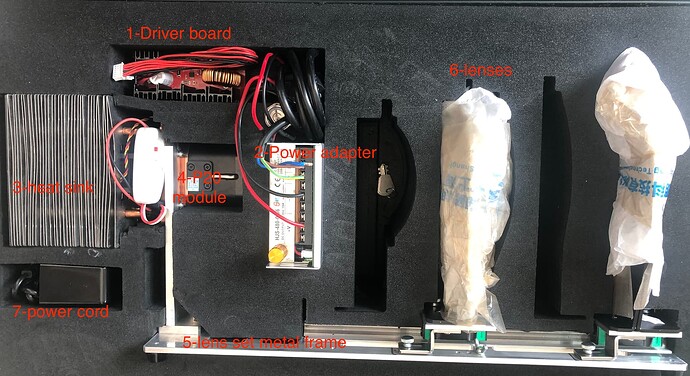

NR2 Pictures:

__

3D printed components:

__

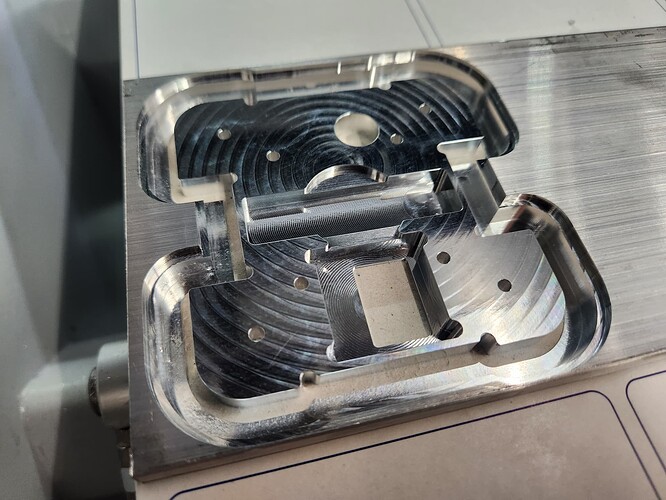

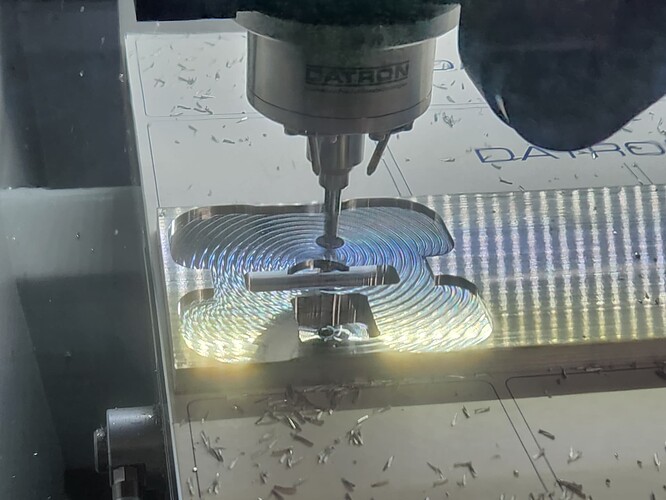

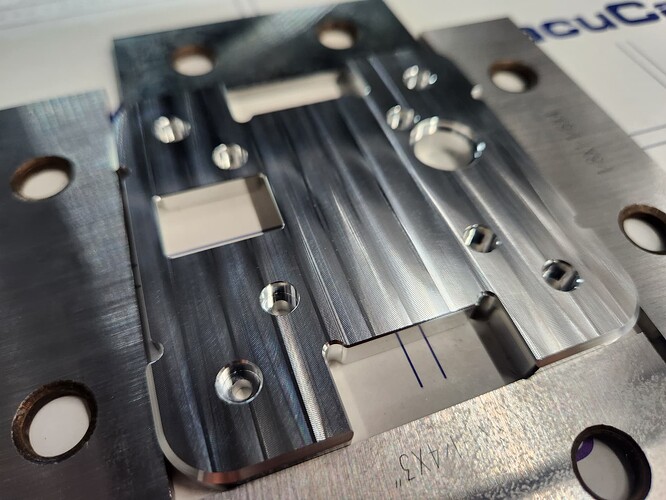

CNC machined components:

__

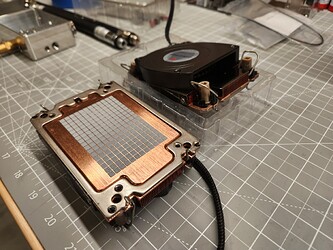

Thermal components:

The heat pipe is directly contacting 5 out of the 7 aluminum parts (2x heatsink, top, bot, back plate), except for the side plates.

.----------------------------------------------

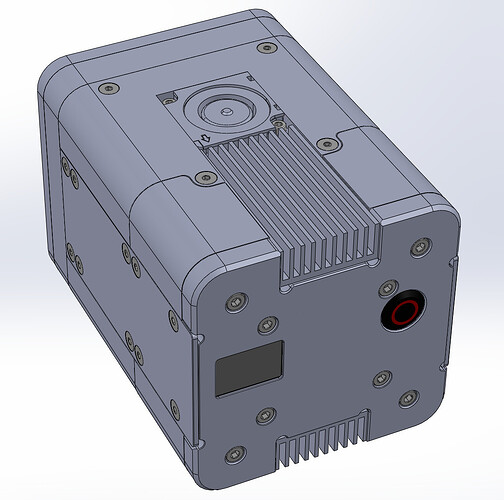

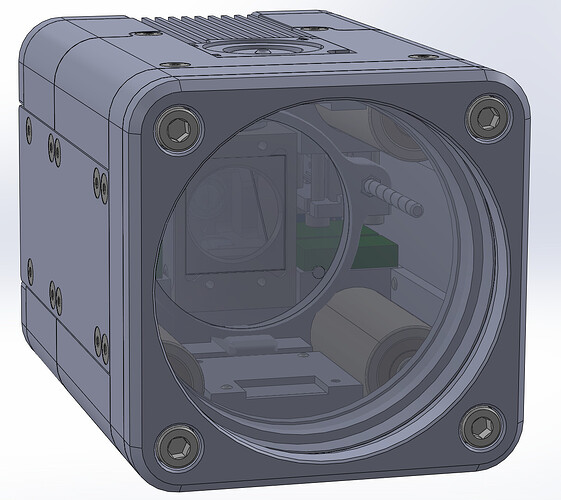

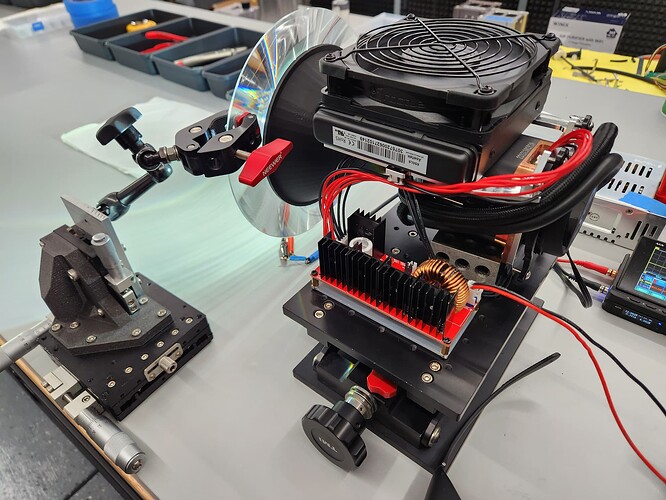

P20 development:

This module is VERY heavy and oddly shaped. It will be very challenging to create a compact system for this. The unit cost for this module is out of this world!!

The beam pattern converges to a point at the front of the module! The recoil reflector design, narrower beam angle, and efficiency of capturing most the light leads to this effect.

Since this is a large design, any customized part will be exponentially more expensive. I wanted to mostly use parts that are standard, or are 3D printed and laser/water cut. Example: https://sendcutsend.com/

I made some progress, and I’m not happy with it yet. It looks ugly.

The current design with AIO cooler can hold up thermally for about 8 minutes before the P20 module reaches it’s limit of 65°C and needs to reduce output power.

While at 11000 lumens, it is only 1260cd/mm². Using a 110mm diameter fresnel lens only gets me Throw value: 10Mcd / 6300meters

Cooler is an “AIO cooler for CPUs”. They are widely available for cheap.

I will need a 12S lithium battery pack to drive this module.

Current Progress:

If I were to jump back into developing this, I would try fitting coolers from Dynatron:

https://www.dynatron.co/air-cooler

They are really well made for their price (~50USD). The bottom is a vapor chamber. These things can disperse about 220W of heat for CPUs. But that is assuming it is operating at 90C. So probably 130W of heat for a limit of 65C.

P20 Pictures:

I was able to make a very compact boost driver (V1 left, V2 middle, V3 right):