Some Tips for safer usage and prolonging the life of common types of Li-ion batteries.

Never let a Li-ion battery go below the minimum allowable voltage, which is 2.5Volts or 2.75Volts depending on the battery model. Doing so, even for brief periods will permanently damage the battery. It will irreversibly reduce its safety and storage capacity. Dendrites or shunts begin to form between the electrodes inside the cell which could eventually lead to partial or complete internal shorts. They grow like crystals and a combination of factors could lead to eventual failure.

Some factors increasing the likelihood of this happening are the age of the battery, the number of cycles the battery has undergone, the extent and frequency of over discharge, and the charge / discharge currents used. Li-ion packs that have been under stress are more sensitive to mechanical abuse, such as vibration, dropping and exposure to heat.

Lithium-ion operates safely within the designated operating voltages; however, the battery becomes unstable if inadvertently charged to a higher than specified voltage. Prolonged charging above 4.30V forms permanent plating of metallic lithium on the anode, while the cathode material becomes an oxidizing agent, loses stability and produces carbon dioxide (CO2). The cell pressure rises, and if charging is allowed to continue the current interrupt device (CID) responsible for cell safety disconnects the current at 200psi.

Sometimes there may be warning signs of a failing battery and these can include fast self discharge or excessive heat while charging. If this happens or if you have overcharged or over discharged the battery, do not use and send the battery to a recycling depot. The better and newer types of Li-ion batteries include more safety features. Visit Battery University on the internet for more information. Do not abuse Li-ion batteries. Over charging / discharging, excess heat and mechanical abuse are a few things that can lead a battery to thermal runaway. Once this process begins, it cannot be stopped. During thermal runaway, the battery may very rapidly exceed 150DegC and the pressure inside could rise to 500psi. At this point, a safety membrane will burst letting the battery undergo controlled rapid venting with flames. If the device it is installed in leaves nowhere for the pressure to go, the device could explode.

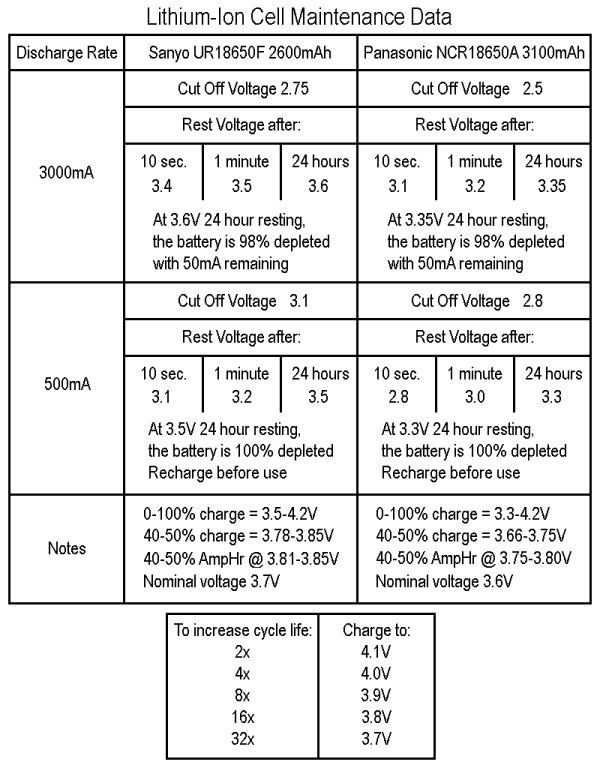

The following examples are an approximate guide only.

Example 1. Sanyo UR18650F 2600mAh, minimum Voltage is 2.75Volts.

At a 3amp continuous discharge, when the voltage under load reaches 2.75 volts, the load must be disconnected. 10 seconds after disconnection, the battery will show approx. 3.4 volts. One minute after disconnection, the voltage will rise to approx 3.5 volts. 24 Hours after, it will show approx. 3.6volts. At 3.6V 24 hour resting, the battery is 98% depleted. It will have approx 50ma remaining capacity and should be recharged before use. At 3.5V 24 hour resting, the battery is 100% depleted and any use without recharging will permanently damage the battery. At 0.5A discharge, the numbers are approx 3.1v, 3.2v and 3.5v respectively. Since 0% - 100% charge is 3.5V - 4.2V, 40% - 50% is 3.78V - 3.85V and nominal voltage is 3.7V. However 40% - 50% AmpHr capacity will be approximately 3.80V - 3.83V.

Example 2. Panasonic NCR18650A 3100mAh, minimum Voltage is 2.5Volts.

At a 3amp continuous discharge, when the voltage under load reaches 2.5 volts, the load must be disconnected. 10 seconds after disconnection, the battery will show approx. 3.1 volts. One minute after disconnection, the voltage will rise to approx 3.2 volts. 24 Hours after, it will show approx. 3.35 volts. At 3.35V 24 hour resting, the battery is 98% depleted. It will have approx 50ma remaining capacity and should be recharged before use. At 3.3V 24 hour resting, the battery is 100% depleted and any use without recharging will permanently damage the battery. At 0.5A discharge, the numbers are approx 2.8v, 3.0v and 3.3v respectively. Since 0% - 100% charge is 3.3V - 4.2V, 40% - 50% is 3.66V - 3.75V and nominal voltage is 3.6V. However 40% - 50% AmpHr capacity will be approximately 3.82V - 3.85V

The rated cycle life is for full charges and discharges. If you do partial cycles, say from 3volts to 4.05volts, you will get around 3 x the number of useful cycles.

Charging to 4.30V will decrease cycle life 0.5x

Charging to 4.25V will decrease cycle life 0.7x

Charging to 4.20V will give the rated cycle life

Charging to 4.15V will increase cycle 1.4x

Charging to 4.10V will increase cycle 2x

Charging to 4.05V will increase cycle 2.8x

Charging to 4.00V will increase cycle 4x

Charging to 3.90V will increase cycle 8x

Charging to 3.8V will increase cycle 16x

Charging to 3.7V will increase cycle 32x

Li-ion batteries deteriorate with age. If stored room temp at half charge, the permanent capacity loss is 2% per year. If stored at full charge, they can deteriorate 20% per year. Higher temperatures increase and lower temperatures reduce this. They are shipped from the factory at optimal charge for storage.