Summary:

- 16.8 Volts (2P4S)

- Attiny13a swap with JonnyC's Star Momentary modded by Tom E for strobe:

- PWM's 1,3,9,27,81,125,255

- 90 second turbo time out

- LVP

- Momentary switch that bypasses MCU for full power:

- Can be used while any mode is on to create unique signals.

- Can be used if desperate and LVP is not letting light work

- Lock-out switch installed

- 7 amps per emitter. Yay!

Saw that a new TK75 is coming out. Sounds great. Big head (but still reasonable sized for jacket pocket carry), light weight for size, shallow reflector for wide spill, and 4 emitters (the perfect amount and beam pattern). I want one but don't have the bucks for one. So I looked at mine and decided it's time to upgrade. Liked what RacerR86 did here. Based on that mod, it appears the TK75 has hardy XM-L2's.

I've been wondering how the HX-1175b1 driver would do with 3S hardy XM-L2's and 4S cells. Buck drivers generally have less ripple if the load's Vf is near the input voltage. 3 XM-L2's in series should be able to absorb more ripple than 1S or 2S. Since the TK75 has a neat thick copper emitter base and great thermal path, I had no choice but to go that direction. RMM has a nice TK61/75 driver option here.

Another thing most lights don't have is a way to manually signal. This light has 2 momentary switches. So one will bypass the MCU and feed VCC directly to the buck converter pin that is feed PWM.

I haven't seen many good tear down pics. So I tried to squeeze in a few here, but also tried to not take pictures that would be redundant to RacerR86's thread. So here goes.

Top of Head:

Not much to do here. The integrated shelf is nicely finished and flat. Also, the leads are thick and short.. Only things that bothered me was a very rough finish to the bottom of the emitter base and not enough thermal paste. So Lapping, more paste is all was done up here.

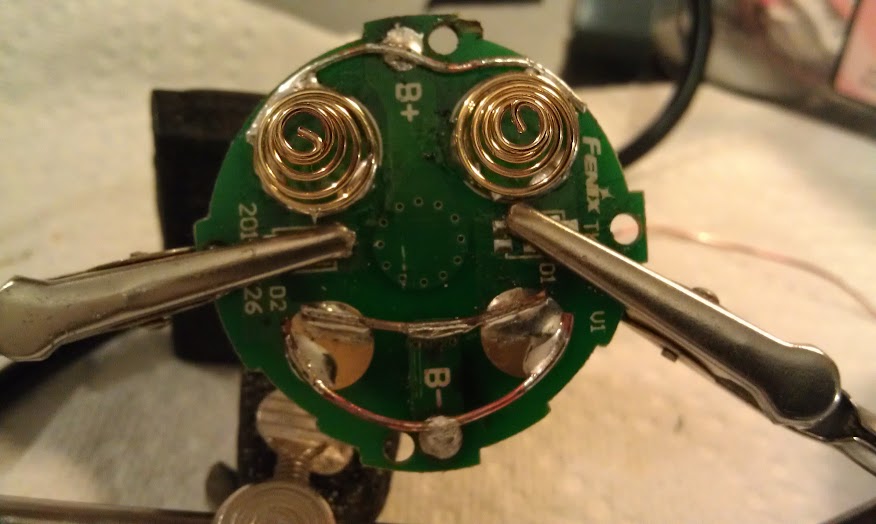

Driver:

Cavity:

There is not enough vertical space for the driver in its stock form, but there is plenty of air space in the plastic spacer to relocate the large inductor. Used copper sheet to make an adapter plate.

Low Voltage Proction. 100K R1, 5.1K R2.

MCU and Momentary Switches. Put an Attiny13a on one of wight's OSH Park adapter boards just to protect the pins. PWM has to be soldered directly to the pin though. Used Star Momentary with Tom E's strobe mod. PWM's 1,3,9,27,81,125,255. Will be tuning the turbo timeout and LVP based on results from usage. When I get happy with the settings, I will report them.

Connection to battery carrier contact plate.

Needed a way to deal with parasitic drain. Used an old Judco switch that has been in several lights. Used an RCA jack center post for a plunger and some thick grease for water resistance. Would like to change this in the future to be water proof.

Battery Carrier:

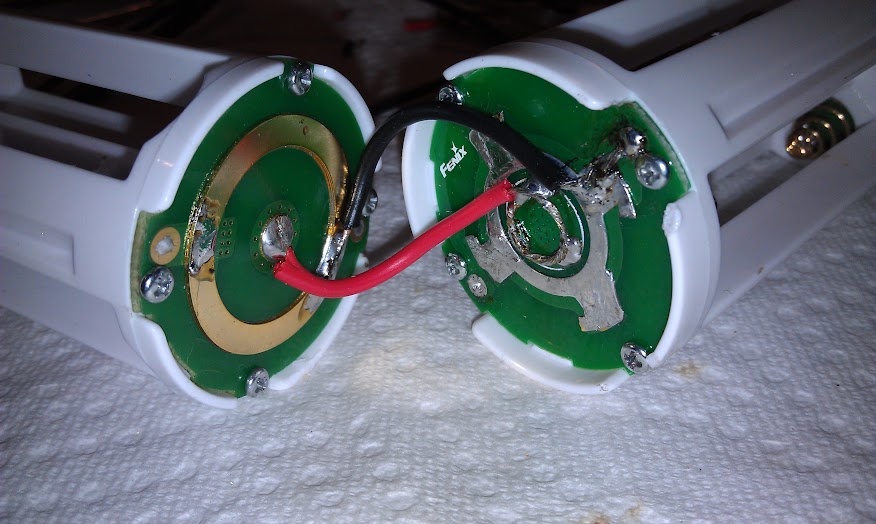

Used 2 carriers to create a 2P4S configuration. Each individual bank of 2 cells is connected in parallel so that they remain in balance with each other. The carriers will be permanently connected as neither will work alone and one only a top and the other only a bottom.. The mod will involve the following:

- All carriers:

- Remove all brass rods (2 per carrier).

- Bottom carriers:

- Bridge positive cell contact pads to each other.

- Bridge negative cell contact pads to each other.

- Bottom PCB of Top carrier:

- Remove diodes. This will disconnect the positive to negative path.

- Connect the positive cell contact pads to the nearest side post (formerly a negative brass rod contact point).

- Connect the negative cell contact pads to the nearest side post (formerly a positive brass rod contact point).

Some stuff inside the carrier.

Here is modded Bottom PCV of Top Carrier.

Here is Bottom PCB of Bottom Carrier. Just joined parallel cells. The Top PCB's are already joined in the stock PCB.

Beams Shots:

Before, Mouse over is after. After was taken aft rain with high humidity. So moisture in the air absorbed some of the light.

Conclusion:

Mas brighter and lots of mode options now. Miss the variable strobe though. The emitters seem fine at 7 amps. The MCU by-pass switch really increases the range of things the light can do. There is audible hum in modes 4, 5, 6. Mode 6 is by far the loudest. Potting the MCU should help, but would like to figure out how to resolve with FW first.

Hardest part for me was "fixing" the carrier.

Hardest part for me was "fixing" the carrier.