Possibly… but it does not have the heatsink and may not be able to handle as much power. They don’t say what switcher chip that they use, and there are usually some hidden gotchas on just what the allowable range of input/output voltages and currents that they can handle.

Wow! Today I received the "AC DC 24V to DC 12V Converter Power Supply Voltage Regulator Waterproof Module" I ordered on May 2nd! Came China Post. Tracking never updated (still says processed through a sort facility in China). EDIT - This was my fault. I forgot to switch tracking to USPS in my tracking app.

It's as expected, a nice solid module. Highly recommend this seller. Not sure when I'll get around to trying it out though as I've got a lot going on.

-Garry

+1

I made an array of 20 5mm LEDs (5x4 in series) to light a shed using a 12v motorcycle battery and a small solar panel. It’s remained totally maintenance free for 10 years! Of course, the battery output isn’t what it used to be but the LEDs are still plenty bright. I wouldn’t hesitate to run 4 XMLs in series for the easiest, most efficient and trouble-free 12v headlight system.

Why dont you just buy two of the new 4x Skyray Kings and strap one to each side of the hood away from the exhaust heating? Then you justify purchasing more SRKs too and can use them for whatever else later ![]()

Well the last time I mowed (a week ago) I ended up mowing into the dark. Flipped on my headlights and was disgusted like usual (currently the higher wattage replacement bulbs). I then had the idea to pull out my EDC (Convoy S2 w/ XM-L T6 4C @ 2.1A) and use that - Wow! Usually more than enough light on high and pretty much enough on medium (40% -> 0.85A). So I verified that two XM-L's @ at least 1.0A each should be enough (higher the better of course :) ). The 4C tint was good, although now I'm thinking to go a bit warmer, perhaps higher CRI as sometimes I still struggled to make out cut vs. uncut grass at times. The XM-L's I bought and have allotted to this "mod" are T6 3C's, so even less warm than the 4C I tested. It was nice being handheld so that I could turn the light where I needed it (so perhaps a headlight should be used too, or I could add more XM-L's for side lighting :) ).

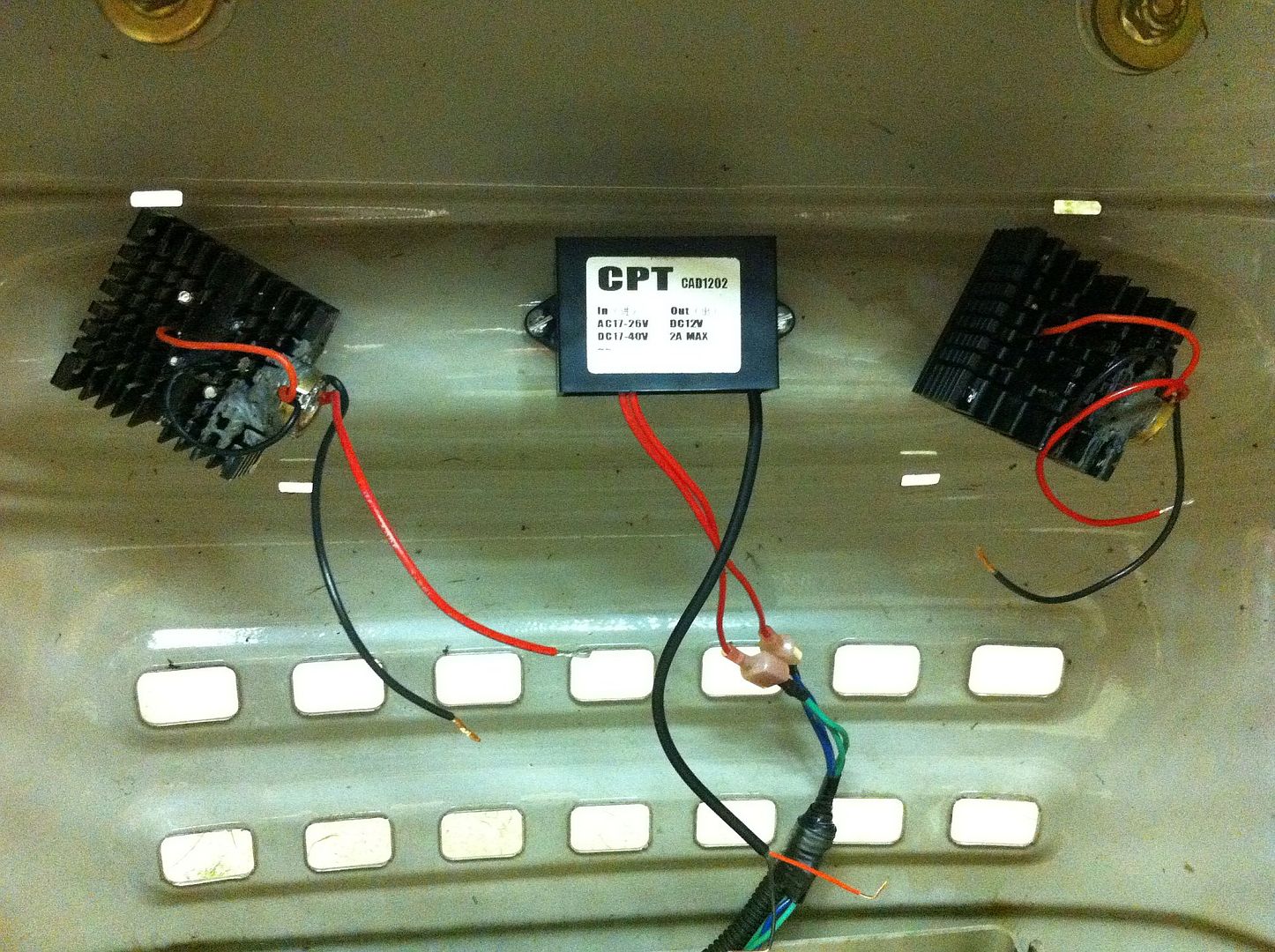

Due to that frustration last week I've finally started building my setup. I gathered up two cpu heatsinks (hope they are large enough), sanded off the anodization, and mounted P60 pills to the sides of them for driver mounting. I spent quite awhile going through all the Chinese packages on my workbench to find the supplies I had ordered!

I'll post up a build thread once I finish. I am taking pictures along the way and will be sure to get before and after beamshots! Of course my wife thinks I'm nuts!

-Garry

Well I've been making pretty good progress on this project for the past few weeks now. I do plan on doing a "build" thread once I'm finished but wanted to share some info and a few photos. First of all that AC-DC 12v regulator from Ebay works great (remember, the headlight wiring puts out 18v AC)! I get a steady 11.98v DC with no load no matter the throttle position (voltage does not rise/fall with the throttle).

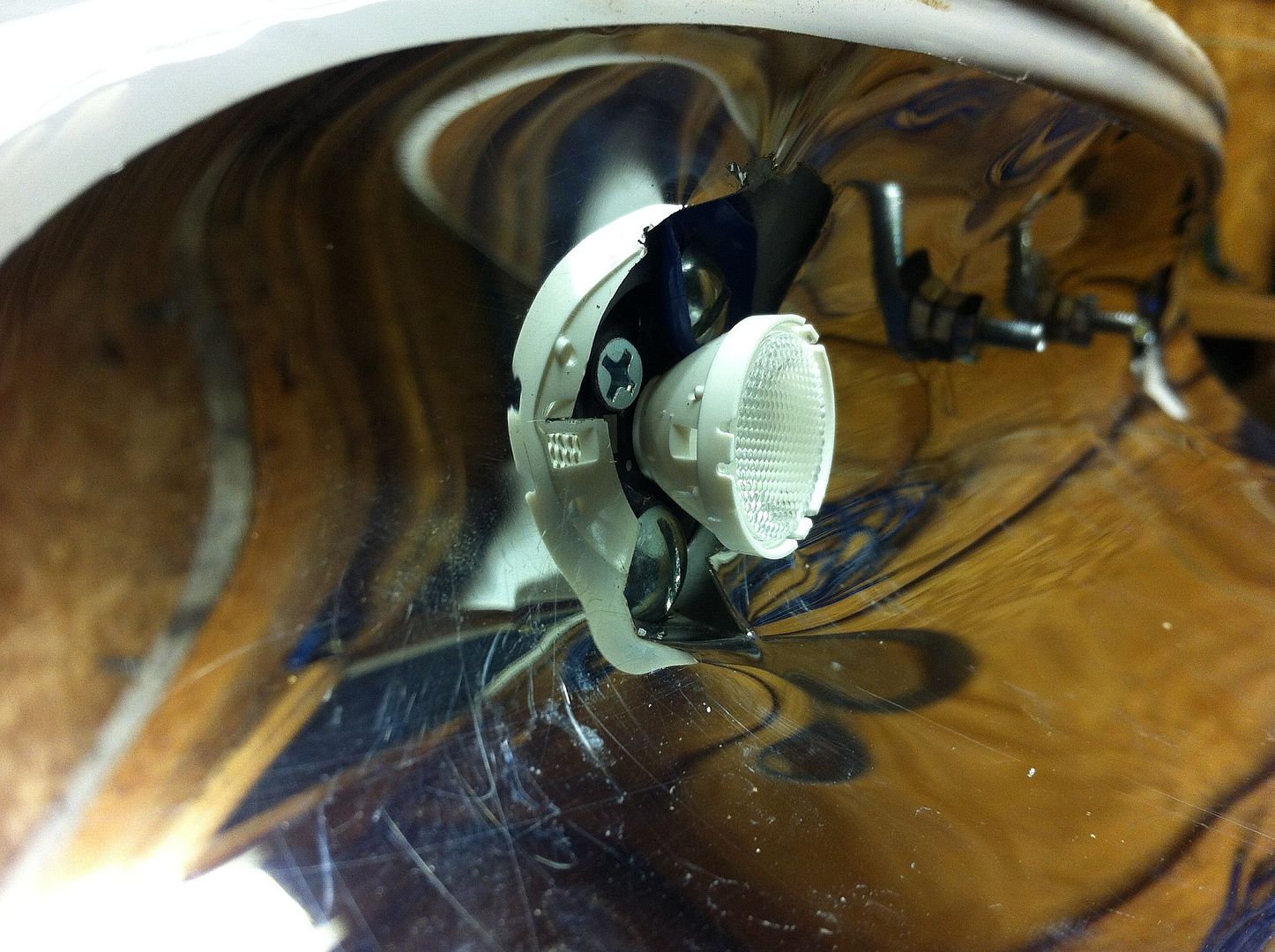

Here's a pic of my homemade heatsink modules mounted (front emitter view):

In the above photo you can see where I completely goofed up my measurements for the mounting screws (large head screws) placing them way closer to the emitter star than I intended. It works, but I had a heck of a time not shorting out the positive wire to ground (notice the blue plastic "washers" - they are cut from a coffee can lid). "Test for shorts first before applying power" is my new saying!

Rear View:

You can see in the above photo how I tapped right into the existing headlight wiring with terminals (and taped back the second headlight wiring).

Another goof up (just keepin' it real man, keepin' it real):

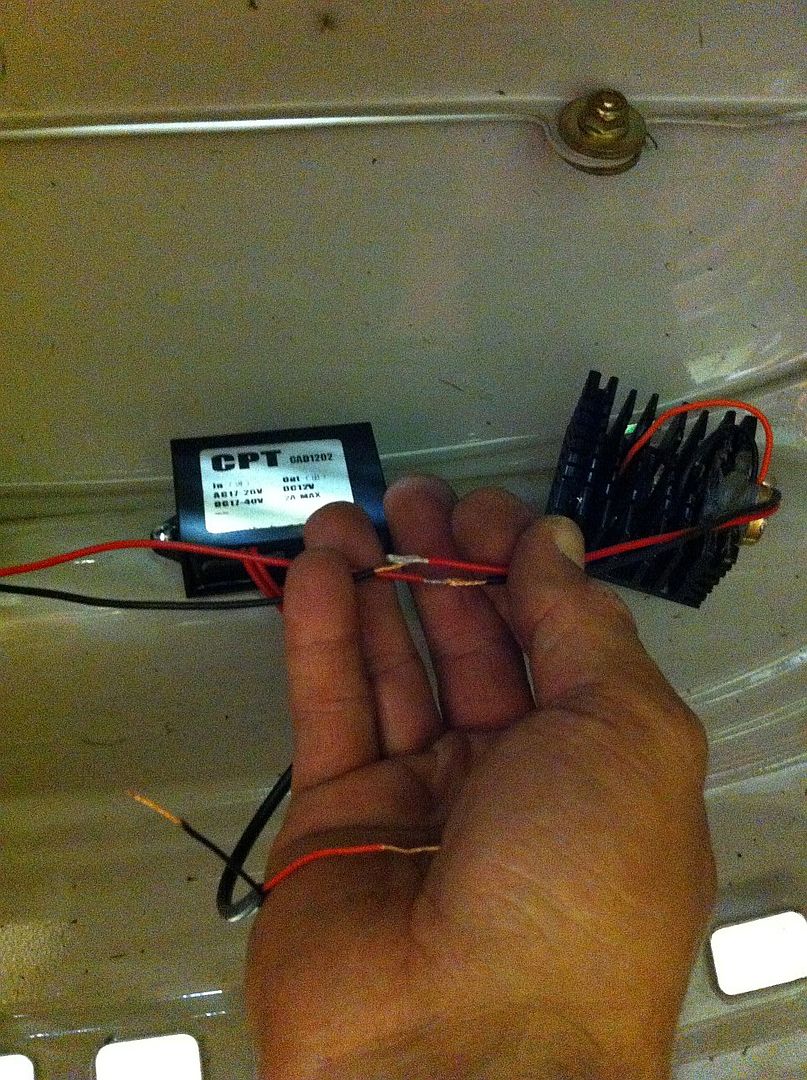

DOH! My wiring is too short! Double DOH!!! In the pic it looks like I am holding them in order to show positive going to negative, but that's just the way it turned out. The 3 positives go together and then 3 negatives go together (2 to driver, 1 from AC-DC Regulator).

Well I pulled the wires together and used alligator clips to keep them connected while I fired the mower up (lights don't operate unless it's running). And guess what . . . they work!!! The optics aren't mounted yet so it's full flood "candle mode". The output wasn't bright at all, but I'm figuring it's an optical illusion do to no optics in place. The front end of the mower (under the hood where the regulator / drivers are mounted) gets really hot due to the exhaust being on the front lower side of the engine; hope my work holds up to this heat.

You may have noticed in another thread that comfychair has talked me into going with the LM2596 modules to drive the emitters, even going so far as to setup low beam and high beam output levels operated by a toggle switch. This is because in my testing of the single mode KD driver the output is rather disappointing - only about 1.36A to the emitter.

Getting closer!

-Garry

what a great update, looks like you’re doing a fine job! Can’t wait to see the finished product and beam/ grass shots ![]() I don’t have much to offer other than it might be worth trying out an elliptical optic and to think about putting another light as low as possible. I’ve tried mowing with a headlamp and it’s nigh on impossible to see where you’ve cut as there aren’t any shadows to see. The lower the light, the longer the shadow cast or, put another way round the lower the light, the smaller the difference in height you can easily see.

I don’t have much to offer other than it might be worth trying out an elliptical optic and to think about putting another light as low as possible. I’ve tried mowing with a headlamp and it’s nigh on impossible to see where you’ve cut as there aren’t any shadows to see. The lower the light, the longer the shadow cast or, put another way round the lower the light, the smaller the difference in height you can easily see.

now, the only downside would be that you can’t see round corners as well, so if you’re planning on doing some high speed/ high G cornering, you may have problems.

Hmm . . . wonder if I could deflect more light downward. I bought these 60 degree optics for this mod. I also have these 30 degree optics based on one of Old Lumens Mini-Mag mods. I did quickly try attaching the 60 degree ones but they wouldn't attach and I didn't want to force them. There is also a plastic "lens" which covers the entire front headlight area (see pic in the O.P.) which has some sort of elliptical diffusion built in. I'm hoping I don't lose too much light putting that back on. I need to play with "lens cover on", "lens cover off", "optics on", "optics off" to see what works best. I was hoping for a wide bright flood (little throw) so as to work for "cornering" too. The single XM-L flashlight test was good enough to get by so I don't see why these 2 XM-L's can't work even better.

Umm . . . no high speed mowing happening! And when I'm not mowing but just using the mower for other purposes there aren't many obstacles to deal with.

-Garry

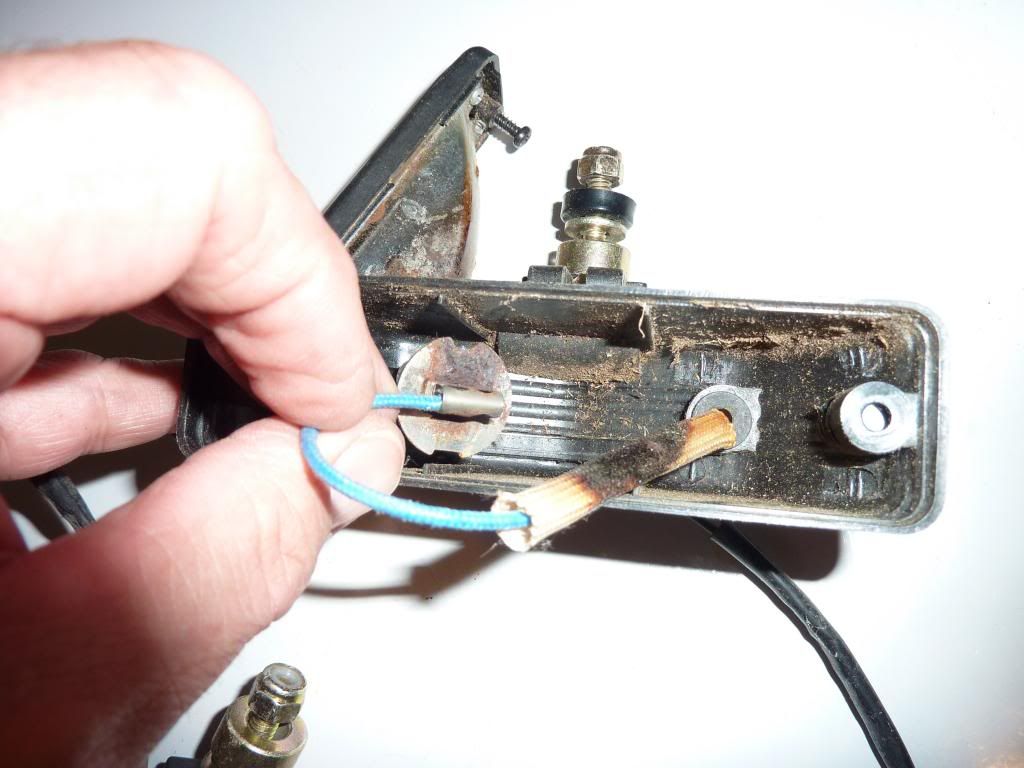

The headlights on my mower burned out some time ago, a combination of heat and moisture. The environment that have to live in is just too extreme. Here is a pic of the original Halogen fixtures.

From the picture you can see where extreme heat from the halogen bulb scorched the wire and where moisture corroded the socket for the bulb. Both fixtures failed this way shortly after I got the mower. So whatever I do to replace these has to be better than the original.

garrybunk, I worry about those black heatsinks that you have mounted your XM-L’s to. From your picture, it appears that they are mounted under the hood, in proximity of the engine. It gets really hot under there when the engine is running. Additionally, the heat sinks, being black will absorb radiant heat from the engine and perhaps the muffler. Without the LED powered, it is quite possible that they could reach 200-250 degrees just from the heat absorbed in the engine compartment.

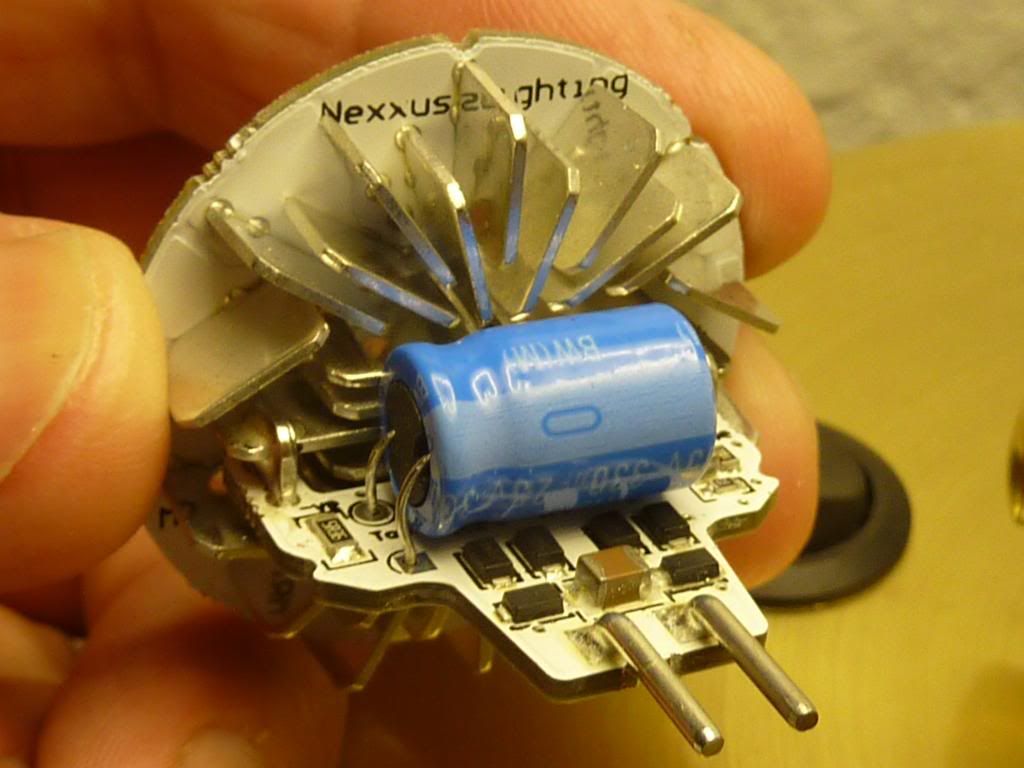

Because of this, I have postponed (procrastinated) doing anything. Anyway I was in Lowes the other day and ran into these on the clearance table. They were only $1.25 each and I couldn’t pass them up. There were 7 so I grabbed them all. My first thought was to use them on my mower. They are M16 base 12V with 8 emitters each. Rated at 313 lumens each (not Chinese Lumens, but real lumens) I would like to mount these in a separate enclosure, water tight and away from the heat. Even so just being outside in the heat of the day might be too much for them.

Each one has its own 12V driver with an integrated bridge rectifier, it’s those 4 diodes in a row near the pins.

I think these could work well if I can ensure that they will survive. meanwhile I just continue to procrastinate….

Of course you found a deal at Lowes! :) What tint are those? I briefly thought of those MR16 bulbs, but they weren't bright enough (just judging lumens #'s) and I needed/wanted a nice neutral white tint in order to see the detail of cut vs. uncut grass.

Yes, it sure does get hot there. I don't have any other solution though except to perhaps put in a sheet metal deflector of some sort to keep the heat from the muffler down low. With my new setup (just got those LM2596 boards in today) I will mount the circuits back under the "dash" away from the heat. I'll just have to see if the LED's survive.

-Garry

You might want to measure how hot those sinks get on there own, while under the hood.

Yes, the sheet metal would help a lot. You did a good job - you realize you started this thread 18 months ago right? Perfection takes time!

Here is more info that you might want to know on this light.

4 - 7 of these would be really bright!

Basically it says 304 lumens, 2829K and CRI 82.9

If I don’t use these, there is always this as the easy way out. ![]()

I was concerned about too much current draw with halogens. I don't think the lawnmower's recharging circuit can handle too much more than the stock bulbs.

-Garry

OK, I now have a problem with my 60 degree flood optics. I guess they were supposed to just snap over the emitter, but they don't. They will barely hang in place but then just fall off. So I need a way to hold them on that isn't permanent (as I will likely be swapping out these emitters for a warmer tint soon and don't want these all messed up). Any ideas? I was wondering about using very little high temp RTV silicone. Will that work? Anything better?

Here are a few pics of what I'm using:

Thanks!

-Garry

I think hot glue melts around 300-400 degrees F and it generally can removed cold fairly cleanly. Question it, would it soften up too much from the engine heat. I have used them on 3 watt emitters driven as hard as they could and the glue held up well on some off road lights.

Clear RTV silicone works fine, just use 3 equally spaced blobs and try not to get it all the way down into the joint so it'll be easy to cut with a razor later.

That holder is just to locate the optic on the LED, it doesn’t hold it there. I’d use non-acetic acid silicone as it is flexible enough not to crack with vibration or shock. I’ve tried hot melt glue and 5min epoxy and both eventually failed with use. I put a very thin line where the holder will sit, squish the optic down and let it dry. Then I build up the silicone between the star and the holder. To remove the optic, just pull and it comes right off. The silicone is a bit of a hassle to clean off the star, more so than hot melt glue, but it doesn’t take long.

to get more light downwards, you’ll have to physically tilt the LED down - the 60deg optics you have will throw a bit more down, but waste just as much upwards, which is why ellipticals are so neat for this sort of application. Still, optics are cheap and they’re not hard to swap in and out until you find what you want.

As for heat, a baffle would probably help, but at the end of the day you just have to try it and see. If it doesn’t work, I’m sure you’ll figure out something else!

Ok, I thought regular clear RTV wouldn't withstand the heat. The "non-acetic acid silicone" - think I may have trouble identifying that. Is it clearly labeled as such? At Home Depot?

I thought Hank's pic on the product page showed the optic "clipped", guess I was wrong.

Thanks,

-Garry

Plain-jane clear silicone, Permatex or whatever, from the auto parts section. If it gets hot enough there to damage it the LEDs will already be dead.

Ok, I just did a little goggle-fu and came to the conclusion to try that as "neutral cure" (ie. non-acetic) silicones are hard to come by and somewhat expensive.

Thanks,

-Garry

heat won’t be a problem. It is awkward to find - I spent a while in Home Depot reading the labels to find one that didn’t have acetic something or other in it (it makes the acetic acid/ vinegar smell as it cures). Can’t remember the name of it, although I can check my tube when I’m back home on Sunday.

You can probably use any old silicone for this, but it’s not recommended for electronics, especially in a sealed space, as the acetic acid fumes will corrode circuitry. I had this happen on a light I made many years ago, so I’ve avoided it since then.