I know this is an old thread, but I still want to share my recent findings.

REF:

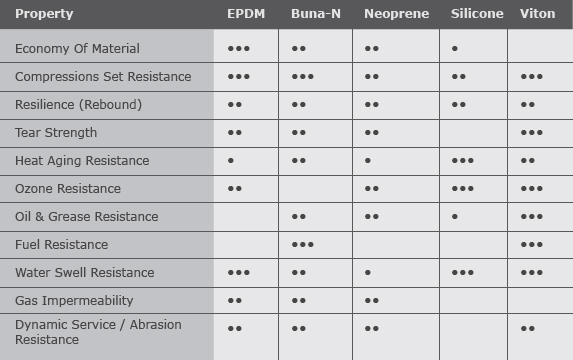

Marco Rubber NBR vs SIL vs FKM vs EPDM

Marco Rubber O-Ring Permeation Chart

TRP Types of Polymer

NBR is probably the most no-brainer and go-to solution. It’s usually black and is actually the most common o-ring material, easy to get. It has a suitable temperature range, chemical resistance, wear resistance, and gas permeation resistance. You can use common silicone grease for lubrication.

Silicone, while perhaps the most common flashlight o-ring material, isn’t actually that suitable. TLDR: I’d avoid using them. Silicone o-rings often come in clear, red, or black. When they’re black, honestly I find it hard to tell if it’s NBR or silicone, maybe NBR relatively harder.

Silicone offers an excellent temperature range but has poor wear resistance and gas permeability resistance. Therefore, it’s unsuitable for both threads and lenses. Silicone has the highest gas permeability among common o-ring materials, potentially increasing the risk of moisture ingress in high-humidity environments and causing gas or water absorption(sucking in) during rapid temperature changes in flashlights. Additionally, silicone has poor short-term resilience, which may lead to poor sealing when the flashlight expands and contracts due to temperature changes.

My flashlight previously used silicone o-rings without issues in extreme high humidity, but I did a relatively extreme test. When my flashlight was hot, I put it in cold water (I know this is a situation to avoid if possible). With the silicone o-ring, significantly more moisture entered compared to when using FKM o-ring.

But since flashlight isn’t rocket science, you see many lights using silicone o-rings that function perfectly. In fact, perhaps because flashlight isn’t rocket science, silicone’s softer property might allow it to fit lager tolerances, which could explain why some manufacturers still prefer silicone o-rings.

Whether silicone o-rings can be used with silicone-based grease is somewhat controversial, likely depending heavily on the formulation or manufacturer’s compatibility list. I choose to avoid this controversy by using PFPE grease or non-silicone o-rings.

FKM is similar to NBR but offers stronger chemical resistance and lower gas permeability, though it performs worse at low temperatures. Depending on the brand and formulation, different FKM o-rings may exhibit slight variations in low-temperature performance and gas permeability. FKM’s wear resistance is generally considered comparable to or better than NBR. I’ve now replaced most o-rings in my lights with FKM, whether for lenses or threads. FKM’s strong chemical resistance means it works fine even with lithium-based mineral oil lubricants. While most FKM has lower low-temperature performance, it’s still rated to -20°C, which is sufficient for my environment. Also at these temperatures, liquid water is rare and humidity is typically low.

EPDM offer better resistance to hot water and steam, along with low gas permeability and cold resistance comparable to silicone. However, its chemical resistance is weaker. If your environment involves exposure to fuels, mineral oils, or cleaners based on these substances, it may not be the best choice. Since I don’t use flashlights in hot water or saunas, I haven’t tested this myself.

Supplementary: since lubrication can reduce gas permeability, I also use lubrication for lenses o-ring, actually this is also a common practice in the watch industry. I’d recommend using PFPE-based grease (e.g. Krytox™) whenever possible, as it is compatible with almost all O-ring materials. Silicone-based greases can be a potential risk with silicone o-ring, may or may not, depending on the formulation.

Also, I found the compatibility tables for these two greases that are often recommended by the community.