Progress! I carved out some time to hopefully finish the ‘turd’ so away we go! Next up is cutting the driver pocket. Since the aluminum stock is just…stock, it needs a shelf/recess for the driver ground ring. So, let’s make one. Step one is marking out the areas to remove and to make clearance. I laid the driver on the tube and marked out the edges of the driver outer diameter and the inner diameter of the ground ring. I set my calipers to the correct diameter and scribed a line that I filled in with a Sharpie.

I had to break for a week, but step two is boring out the tube to a larger diameter before cutting the shelf. I tried this with my Dremel and some high speed cutters, then a sanding drum, and it was taking way too long, so I bought a step drill and had at it. I clamped the tube to the table and hogged out the inner diameter to about 24 mm.

Once the hole was hogged correctly, I set to cutting the shelf. You see me with a glove on, well that went on after some high-speed skin removal happened when the cutter skipped and ran across my pointer finger knuckle. Ouch. This was a tedious, high precision exercise since getting it wrong means the driver doesn’t fit right and that could compromise the whole operation, so, yah, I took my time. Now I know why lathes are a luxury.

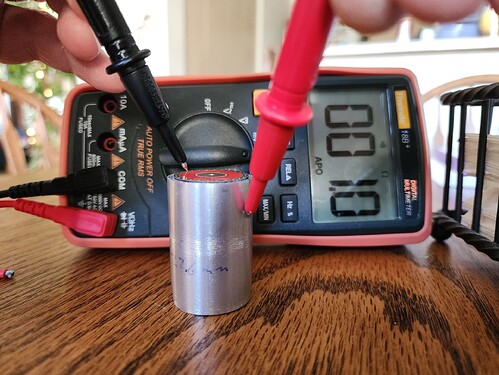

Also it’s important to check for continuity between the driver and pill during this process to ensure a good connection.

Once I was satisfied with the depth and fit up and the ground ring fit flush against the shelf (I did go a bit wide so the driver isn’t fully captured-no biggie though), on to the next item: Drilling holes for the LED wires. What a pain! Again, a drill press would have been awesome here.

Next up: Brazing the pill extension. Step one, bevel the edges of the mating surfaces. You do this because it gives space for your filler metal to bond to the two parts being joined and creates a stronger connection.

I clamped them together and got to brazing. The joint isn’t pretty, but it’s solid and makes a good connection. Another continuity check and things look good. Next, time to address the switch. I added some solder wick between the contact pad and the top of the spring. Then I prepared the driver, soldering on LED wires (22 AWG) and a positive contact spring (a Mtn Electronics BeCu short spring).

Now, on to preparing the LED shelf and adding the MCPCB with LED. The shelf wasn’t perfectly flat, and I spent a good 30 minutes or more grinding it with flat stones and sanding it to get it close. I’ll add extra thermal paste to compensate.

I seated the driver to the pill. I added kapton tape to help hold it in since it wasn’t too secure. The ground has a good connection though.

Final assembly time! Getting close. I added some thermal paste to the threaded part that threads to the tube to help with heat transfer from the pill to the tube for extra heat sinking (it works!). The long pill still fits fine in the tube even after it warped a bit from brazing.

Last steps, testing the electrical connections for shorts and assembling the head. To check for shorts, set your multimeter to continuity mode and test the connections by probing the negative (ground) and positive. If you have continuity, STOP because there’s a short and connecting a battery will either smoke the LED and/or driver (ask me how I know that one). In my case, we’re good, so on to final assembly. I tested the setup before installing putting a battery with the positive against the driver positive and jumping the battery negative to the pill with a jumper wire. If your connections are good, you’ll get light. I did (I was sweating this part) so moving on…

Once the head’s together, installed the optical lens, screwed on the bezel and we’re done! I omitted the plastic retainer for now. I may or may not install it depending on how the beam looks. Time to slang some photons.

It’s super bright. This is the brightest zoomie I’ve ever seen. The hotspot is tight (round) and very intense. The spill in the zoomed out position is very bright and wide.

The tree in the below photo is about 200 meters. It easily reaches the tree.

The beam looks better than I expected without the retainer. I may paint it black and ream out the hole to fit the LED better, but that’s down the road. Overall, I’m super pleased with this project! I’ve been wanting to do it for a long time, just never had the time or motivation to do it, but I’m glad I did. I took the mostly awful Gearlight S2000 and made it into a serious flashlight that’s usable and reliable. It does get pretty warm on Turbo mode when the stepdown isn’t set (I’ll get around to it), but all that thermal mass takes a little while to heat up. The heat transfer is also okay (not great), and the tube eventually gets mighty warm.

I didn’t measure the Lumens yet, but a throw test at 5 meters netted 156,750 cd for 791 meters. That’s not on a fresh battery either!

For those interested, here’s the parts I had to buy plus cost for this (not including my time):

LED: L90 from AliExpress $6.75

Aluminum tube stock: $10 from Amazon

Driver: $24 (+ shipping, and the solder wick, springs) from Mtn Electronics

Host: Gearlight S2000 (free review sample, but they’re around $22-$24 on Amazon)

Tools: 1-3/8 step drill $14 from Amazon

Hope you enjoyed this one! It will probably be the last one I do for a looonnggg time, but who knows?

Best