Yes … electrical contacts can build up an oxide layer that has higher resistance. Esp. Aluminum oxidizes easily. There are lubes/chemicals that slow this down but cleaning all contact areas regularly will keep resistance at a minimum.

It’s definitely necessary to do this in high-amp flashlights as it will affect max brightness.

Thank you Valynor, very good information.

Capacity loss and internal resistance are related but not the same thing.

I have an old cell phone with 75% battery capacity but the internal resistance is so high it can’t run the phone anymore. 2013 phone.

Capacity loss is due to chemical changes in the battery, converting to an inert form that cannot accept charge.

Internal resistance is likely related to the separator and chemicals in the battery not operating as good as new. Though i don’t know the exact details.

I am not sure why this is?

I have never had high drain cells that were in a four-cell light last more than 30 months( 2.5 Years)…VTC6 Custom BT

Yet I have numerous single cell lights that require High drains where I used VTC5/VTC5A and VTC5D and had a minimum of 300 Cycles, used consistently for 4 years plus and are still used from time to time. They hold their voltages very well, even after weeks of not using them.

Maybe the Sonys are that much better? I wish they were more available with a decent price like they used to be. I don’t think Murata is going to make them readily available for people like us.

Molicels P26A … one set in a four cell light lasted 20 months. The second set are still in use and are 14 months old …time will tell them.

Single cell high drains, the four cell hi drains setups were all treated equal. Never abused.

I forgot to mention. The VTC5, VTC5A and VTC5D will be 6 years old in June.

Also I just started using 4 X VTC5D Custom BT in my modded X65 mini.

I think I just realized something. These monster lumen/throw lights are producing a lot more lumens and are probably harder on the batteries than a single cell 1000/2000 lumen ![]()

I may have answered my own question!

There’s a lot of things going on. Yes, high discharge cells are used at higher discharge rates and that definitely has an effect.

But also just the properties that allow a cell to be high discharge generally, generally, also cause it to have a lower cycle life. Higher power output means making the lithium ion diffusion path as short as possible. So lower weight coatings are used on the electrodes, the particle size is smaller, more conductive additives are used. Things that just generally make a cell less robust. Usually.

Then one company just finds a better way to do something or a better combination of something somewhere and one cell is just be way better than another one and it doesn’t follow the established pattern. Too many variables, its impossible to say the reason for lower cycle life is “x”, or Sony/samsung/molicel is better because they do “y”. There’s too many factors and a lot of trade secrets.

“Not enough for that LED” implies that the CFT90 only works above 10A. Mine works in moon mode to Turbo mode, so I know that isn’t the case. Whatever is “locking” Turbo mode is a driver related issue more likely as compared to emitter or cell issue.

Multi-cell parallel configurations are usually easier on a cell because the load is shared between the set. It’s really difficult to push an emitter that the forward Voltage goes up to 4 or above with a single cell because by itself Voltage sag under extreme load keeps that lone cell from meeting the high amp drain Voltage needs of such an emitter… like the CFT90 or SBT90.2.

With 4 parallel cells the 25A needs of this kind of emitter can be supported while each cell only supplies around 6A, low enough demand individually to allow Voltage to stay relatively high, at least for awhile.

This set of cells, though, ( a battery if you will ) takes a beating trying to run the demanding emitter over time, running deeper cycles in shorter times, perhaps, than other less hard use lights. Remembering that a cycle is a full discharge and recharge, the hard use emitters are likely to run the battery through more cycles faster, thus reaching EOL sooner.

I built a lot of small 2S 18650 lights back in the day, MTG2’s in single 18650 lights, and those small cells got beaten down quite quickly!

How come it works with brand new batteries as I mentioned?

Maybe the driver recognizes that it’s not able to push the original amps with these older 30q, and it steps down immediately? ![]()

Just to reiterate, the initial step-downs are all from turn on .

The odd thing to me is after 6 or 7 step Downs it locks in. But it never stepped down with new batteries until they’re depleted.

Thx

If you remember back when we started building High amp triple S2s with a fet driver – The MCU would go crazy and reset with certain LEDs ---- I’m thinking this is more of a voltage problem – The voltage sag of an older cell is greater than that of a new cell

Cochise – with new cells-- how far ( voltage) can you run them down before the Turbo acts up – If I had the light and hooked it up to my adjustable power supply – I could tell you exactly when and why it’s doing it’s dance

I bought this light used when it was about 6 months old. I have no idea what kind of driver it is. All I know is it’s custom made by that VIN guy but mostly by Richard from Mountain electronics.

A DMM measures resistance by outputting power with a fixed, known quantity (either current or voltage, i don’t know which) and then measuring the resulting voltage (if current is fixed) or current (if voltage is fixed) in the component, and the resistance of the component is calculated from the two values using Ohms law.

This only works on passive components, it can’t work on a component which introduces it’s own power into the circuit, such as a battery, and connecting a battery to the DMM’s resistance measuring circuit which is not meant to take power input may have consequences.

Hopefully your DMM has built in protection to prevent damage from such a connection.

The internal resistance of a battery can be determined using a DMM and a resistor of known value (with correct power handling capabilities for the power that would be delivered to it), known as a ‘shunt resistor’.

The battery’s voltage both with and without the shunt resistor connected across the battery is measured, and as the difference between the two voltages is be due to battery’s internal resistance this can be calculated with a formula derived from Ohms law.

There are caveats to ensuring as accurate a value as possible, HKJ’s article here contains detailed info on the above, including the formula:

https://lygte-info.dk/info/Internal impedance UK.html

There is also a thread here which shows thefreeman’s solution to making 4 connections to the battery: https://budgetlightforum.com/t/measuring-battery-internal-resistance-always-around-50-60-mohms/65680/7

As I mentioned it only acts this way with aging 30q’s and the first batteries I put in brand new ga’s or MJ ones could not handle the load.

Immediately after activation it starts stepping down.

With new cells it won’t step down until it’s at about 3.50 to 3.55 volts. And this is measured after I get home when they’ve been resting for 20 minutes. So they may have been down to 3.2 3.3 volts I have no idea.

I also repeat this again. There was zero issues when the 30q’s were new and when I put in brand new VTC 5D or Samsung 25s. So the solution is simple, new batteries which I’m going to do.

I’m just trying to have you guys who know more about this give me ideas is why it does that?

Looks to me like the low Voltage protection is at work there. The aging cells immediately sag far enough to trigger the low Voltage step downs. The issue is from the comparatively high Voltage needs of that emitter.

I have a CFT90 in a light I built from scratch but I honestly haven’t used it at length to see what happens to the cell… I run it on a 6,000mAh 32650.

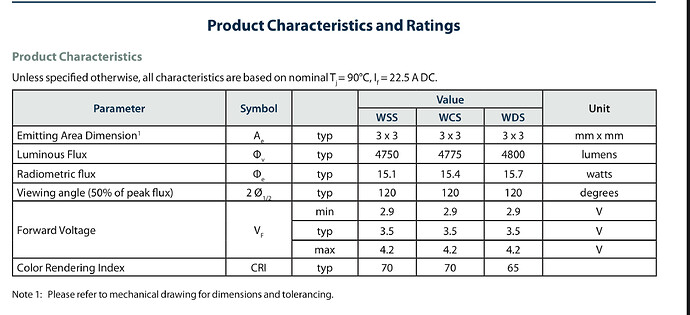

As I thought, the CFT90 has high forward Voltage demands….

Typical at 3.5V, under high amperage up around 4.2V, or equal to/over a fully charged cell.

That makes sense but I still don’t understand how come all the sudden after a half dozen or so stepdowns from initial activation, it’s able to lock in then and run until the batteries are depleted?

Bypasses lvp?

Richard would be the one to ask since he builds Vihn’s drivers.

Ok. Thx

As a vague idea it may be that going to turbo triggers an impulse-like voltage drop which is just enough to cause the driver to drop out of turbo, and that after several activations warmer components or residual charge in components reduces that impulse voltage drop just enough to avoid the drop out of turbo.

You could leave both the torch and the 30Q to rest and then try triggering several turbo stepdowns with a different battery in the torch, and then inserting the original 30Q to see when turbo locks on.

If it locks on immediately it’s the torch that’s changing, if you still need several stepdowns with the original 30Q following several stepdowns on a different battery it’s the battery that’s changing.

I contacted him through Mons Pura recently — Still as friendly as ever with me