I looked briefly at the spreadsheet. But not enough to fully appreciate it. Probably because it was more complex than a quick look would allow. I am not sure why you used a spreadsheet. I think that everything in there would go well in a standard “Word” document. That would make it easier to read and maybe less off putting for some. I am hoping to get back to it. But from what I did see, it looks like it is a good start. The information is solid.

Somehow I was thinking that you were going to document settings that you use for different chemistries and sizes of cells. For that, a column for each setting with values on a line for each battery type would work.

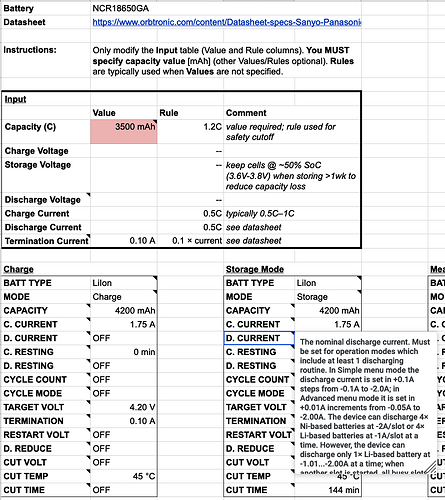

because it’s a calculator. you put in the cell capacity (and, optionally, other inputs), and it makes programs. it also serves as convenient documentation. the cells have useful notes that you can view by hovering.

for example, every program parameter cell has the explanation from the manual built into it. you mostly don’t have to refer to the manual anymore.

you can also read the cell formula to understand how the value was derived instead of just scratching your head.

yes, but so far only LiIon and NiMH since those are the only cells i use.

WOW! That was not apparent on first look. Maybe I would have known better if I looked at more than the first page. I wonder if that was lost on others?? Not everyone is familiar with how spreadsheets work…

I will look closer. Me and spreadsheets never have gotten along that well. I downloaded it as an Xcel spreadsheet. We will see if the macros survived.

i see your point! i added the screenshot to the OP.

Naw it’s probably cuz it’s flawless. Well, the charger section of this forum is pretty dead for whatever reason. So is charger discussion in general. Ever since onboard charging became real common. Too bad. Is there anybody still reviewing chargers beyond just an unboxing video?

I looked at it. Looks fine to me. But I don’t have the charger so idk how this really works in practice. It doesn’t hot when you’re discharging at 0.5c? Must have a good cooling fan.

The most recent version has two fans.

Even the Original model that I use daily and that has a single fan, does not get “that” hot when cycling cells. At least the cells do not get above around 50C.

depends on the cell capacity ![]()

i think it can do 2A (total or per slot, idk)

@SYZYGY, thanks for this! A real help when preparing programs for the MC3000!

One question: I noticed you set the D. REDUCE option to OFF by default for Refresh; I’ve been experimenting with my LG MJ1s and have measured some disappointing capacities (around 3100mAh – that was with “TARGET VOLT” set to only 4.1V, but IME the capacity provided by going from 4.1V to 4.2V wouldn’t make up for the remaining 400mAh – and all other parameters set as per its datasheet).

So now I’ve been experimenting with D. REDUCE set to 0.34A (which is half of the datasheet-recommended 0.68A discharge current), but I’m kinda worried that it could force the cells too much and perhaps harm them – what do you think?

Good question. I am a bit confused as to what the D.REDUCE actually does. Honestly I have never messed with it at all. Sounds like I may be missing something important here. So a good explanation, or some links to help me understand the setting would be greatly appreciated.

BTW, page 22 in the manual did not really enlighten me… ![]()

THX

EDIT:

I re-read the description several times. Maybe this is the important part?

“Setting this option will extend the discharging period beyond

the time for normal discharge cut-off, discharge even more electric charge, but never let the

battery fall below the cut-off voltage.”

So it is a way to take into consideration the recovery process to coax a bit more out of the cell?

So I see the concern @dmenezes mentions. I can also see why setting it to zero may not be good.

So how do people usually set this?

I’ve recently got an MC3000 and have been finding this guide very helpful. The tab for the Eneloop Pros was very informative – I didn’t realize Eneloop released data sheets for their batteries.

I have a mixture of NiMH AA and AAA batteries, with the bulk of my Eneloops being the non-Pro model. Your spreadsheet calculates values differently than the MC3000’s built-in Eneloop mode. In particular, the MC3000’s built-in mode will discharge at 0.2C instead of the 0.5C in this spreadsheet and it sets 2000 mAh as the cut-off (nominal is 1900 mAh), rather than the spreadsheet’s 2400 mAh. I’ve had good luck following the spreadsheet for non-Eneloop NiMH batteries. But, I could use some guidance on the Eneloops. Do you put the MC3000 in Eneloop mode and override the settings or do you treat them as generic NiMH with the spreadsheet settings?

Thanks for signing up, EllenRipley!

First, I seldom use my MC3000 for NiMH. I have a few dedicated NiMH chargers for this. Of course, this means that I am not super familiar with those specific settings. But I think I can give you soem general information.

It seems to me you are concerned by the discharge function, or maybe cycling the cells.

I would think that you would set any capacity cut off for something above the rated capacity. So 2000 to 2100 would be good for the standard eneloops and 2500 to 2600 for the Eneloop PRO cells. This only to allow for the rare case that you have cells that exceed their rated nominal or minimum capacity ratings. I think the capacity cut off is a safety feature. My settings for LIION disable it. In any case, if you set it too low, the only impact is to miss measuring some of the actual capacity of the cell. The voltage termination is what is important here.

As for discharge current, I think both the spreadsheet and the eneloop function of the MC3000 are guidelines. If you want to duplicate the manufacturers capacity tests, find the data sheet and use the discharge current based on that. Typically I like to test at a current that reflects the use case I have for the cells in question. If it is low drain, then I will use the 0.2C. In high drain uses I may test up to a bit below the manufacturers’ max discharge rate.

SO You make the decisions. Both the charger and the spreadsheet merely provide guidelines. Just make sure you know what you are doing so you don’t do something that will damage the cells. Then make the settings that you need to get the information that you require for your situation.

I’m sorry for not being clearer. The spreadsheet copies the default values from the MC3000 guide for NiMH, but then ignores the default MC3000 values for Eneloop batteries. I’m curious why that’s the case. The MC3000 manual indicates that Eneloops have slightly different chemistry from other NiMH batteries and supposedly picked settings that optimize for that. I can’t tell if that simply influences the default values and then proceeds to charge like a normal NiMH or if the MC3000 actually alters the charging mechanism used for Eneloop batteries. I’m hoping someone more familiar with the charge process could shed light on that.

Consequently, it’s unclear if @SYZYGY suggests ignoring the Eneloop mode entirely and treat all Eneloops like normal NiMH or if we should still use the Eneloop charge mode and adjust the default values to match those in the spreadsheet. If the Eneloop charge mode is only a thin wrapper around NiMH mode with safe defaults then it doesn’t matter which mode to use. But, I can’t make an informed decision without more information. Unfortunately, this isn’t an area where experimentation is likely to be fruitful. It can be a long time between making a bad decision (e.g., charge in Eneloop mode or NiMH mode) and detecting cell degradation. Better understanding either the charger or the rationale for why the Eneloop mode is ignored in the spreadsheet would be helpful.

I think that this is due to the fact that many think the Eneloop cycles are just a sort of marketing thing. From conversations I have read, many users simply ignore it and use the standard NIMH cycles for their Eneloop cells. I don’t believe that the actual charging algorithm is any different.

I found this which is interesting as the big difference I found in the Eneloop settings is the dV=-3mV setting for termination. I just use the -0dV setting myself for all NIMH cells.

“In my experience dV=-3mV works only with Eneloop batteries (in perfect conditions) at the preset currents, but generally it does not work with other battery brands and you have to set 0dV. It does not work even with Eneloop batteries not “new” (with internal resistance higher than normal value) and it brings to overcharge batteries due to the inability to detect the end of charge point.”

Though I have a few dedicated NIMH chargers, when I have used the MC3000 for charging Eneloops

I have just used the standard NIMH cycles. I don’t think that you have anything to worry about if you follow the spreadsheet suggestions for NIMH cells with your Eneloops. But do tailor them differently if using the PRO cells due to their different capacity.

hi, guys. it’s been a long time without updates, but perhaps we can revisit the guide and try to improve it as needed. to be clear, i’m not an expert in batteries or in this charger, so i’m sure there is room for improvement. i did try my best, ofc ![]()

feel free to comment/suggest an edit using the google sheet itself. alternatively, we can use this blf thread.

iirc, the eneloop type basically doesn’t expose a few settings that the NiMH type does. i don’t see the harm in using either. it’s been a long time since i looked, though.

i’m not sure if it’s possible to determine the values for settings that aren’t exposed in the eneloop type.

as for why i put NiMH in the guide, i probably did it because it’s more general than eneloop, and also i wanted to get all of the settings fields and associated help descriptions from the manual into the spreadsheet. i probably wanted to reproduce as much info from the manual into the sheet as possible. as for reasoning behind specific values in the sheet, did you have anything specific in mind? i tried to explain my reasoning in the sheet.

to more directly answer your question, you could, for example, use the eneloop battery type and then tweak delta peak and charge current to your liking based on guidance from the sheet/manual.

what i can say is that eventually after a decent number of cycles, the -dV delta peak detection method stopped working on my eneloop pro AAs. i’d get the “capacity cut” error. i did not have the mental energy to experiment with fixing that… i actually just kept charging them with that very same 3mV delta peak setting and let it stop based on coulomb counting, haha. have not had issues yet. the ‘correct’ thing to try is either refreshing them (never bothered), increasing the charging rate, or trying 0dV i guess? however, most of my batteries have been lost (probably accidentally thrown away) by family members, so i only have four of them left.

i just purchased a box of regular, non-pro eneloop AAs, so now i want to play around with this some more.