That is a good start.

I should enlarge part 6, more aluminium for absorption and more plus larger fins for heat transfer

So JasonWW you are telling me that there is asolutly no difference betwen using a switch or not @17A. Ok i have nothing to say to this.

Also so many people are telling you there is something not right with the thermal design (and a few of them alredy have a little bit of experience). And again regardless of what everyboby says you know better.

Please help me. Whats the aim for this light? Most beautifull Flashlight on the shelf or a flashlight (for modders) with the maximum output you can get for a budget price?

One word regarding the thermal abilities. I remember the same arguments when the GT was made (it is enough for a XHP-35, Thats ok , it will be good. . . . ) but a few people pushed untill the design was improved. Now they bring a modkit on the market with a XHP-70. Thanks to the efford of many. Also a multi-emitter light.

Why would someone build something not as goog as it could be if it is not costing anything or the cost is very little for the improvement they gain.

I got no change in lumens. I was hoping I would. I have extra switches to put in, but they were not needed. :cry:

You are not paying attention. I agree it is not perfect. In fact, I say this many times. I am also right there trying to come up with improvements like everyone else. I think some people greatly exaggerate it’s flaws while I see them as only minor.

It’s whatever you want it to be. Just like with any other light.

This is one of the biggest mysteries in life. I don’t know why, yet it is done all the time. Laziness? Ignorance? Maybe there are reasons we are not aware of.

Before people get onto Jason too hard. I am pretty sure that his personal feeling and what he feels that he can get Sofrin to do are getting jumbled up in his replies.

Having worked with several manufactures, a change like this can be quite difficult to properly explain and get them to make, even if it seems simple to us. In which case I think he is just channeling what he thinks their logic is as I have done as well.

Now his personal opinion I am not so sure on, I think he is underestimating the effect that a proper thermal path would have on the overall usability of the light a fair amount but he seems to understand the gist of the argument.

In a nut shell a proper thermal path could allow the light to maintain a significantly higher output over the long term.

A sign of a bad thermal path is the L6 for example that uses a design much like this (except 1 piece, without the threads) where the switch area heats up much faster then the fins and head. This is proof positive that there is very high thermal resistance between the LED and those fins.

This is made double bad by the fact that the switch is the part you touch, not the head.

Overall if they go with the design they have now my interest in this light will drop to “eh, if I find it cheap enough I might get one but I am not going to go hunting for it”.

Well said TA ![]()

Not trying to be annoying, just trying to help developing a nice BLF worthy flashlight.

Page 2 of the K70 thread.

Here the thermal properties were already mentioned and discussed.

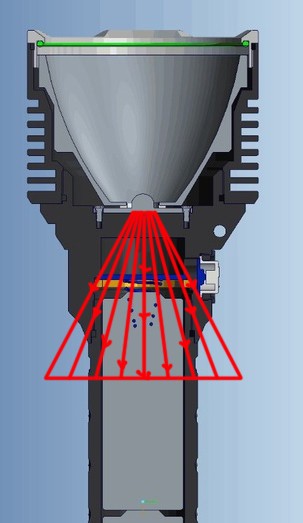

Except that the drawing and post above suggests that the heat is projected downwards which is a bit of nonsense as heat has no direction and will just go the way with the least thermal resistance, in whatever direction that is.

Anyway, we all agree that we need to get rid of the heat on the most efficiënt way.

So fins on top of the head is nonsense, we need a good thermal path around the source of the heat.

My S70 doesn’t really get warm enough in this weather to pass heat to the fins they are only slightly warm even after a substantial amount of time. The S70 has some fins/cut outs around the switch area dont know how much they help they probably need to be bigger. I think the S70 handles heat better then the L6 but that may be because my L6 is clear?

I think heat soaking will be more prominent on this light it will be at least twice the power? My S70 is only around 30w.

We just need enough material to pass the heat to the fins without effecting performance easiest way would be to move the switch or have fins around the switch.

This discussion is getting very interesting, in a very civil manner I might add.

Good and informative info, thoughts, & suggestions. :+1:

.

My thoughts align more with Yokiamy, djozz, & many others as far as heat sinking, heat path, & heat transfer goes. Make it right the first time. It does not cost more to leave metal, it is actually a bit less machining; so cost is slightly decreased.

So make it in the best possible way as far as shedding heat. No valid reason not to.

FORM FOLLOWS FUNCTION

Function first.

Form second. :+1:

JasonWW, thank you of spearheading this project.

Without you, none of these discussions/opinions would be possible.

You are appreciated.

/\. +1 …. ![]()

There is a bit of disconnect as I’m not working directly with the engineers. I go through a middle person (Cissy? I guess I should ask their name) who is a translator and not familiar with all the technical stuff.

So I have to simplify and use pictures as best I can to get the ideas across. It is difficult.

:person_facepalming: … Ouch, you’ve got your work cut out for you Jason… :person_facepalming: … ![]()

To say the least……

I just heard back from Tracy at Sofirn.

Unfortunately, they are not able to switch to a one piece head design because: “one piece head is very different for us due to machine knife and CNC time.” So it will still be a two piece design. They are going to extend the threads between the two which can only help heat transfer.

On a more positive note, they said they can make some changes to improve the heat flow.

I sent my latest set of ideas to them:

They said they can do ideas 1、2、4、5, but not 6. “It’s hard for us to make 6. It’s hard to explain, but if we can do this, we will. But if we need to purchase new machine or too much machine work time, I’m sorry that’s too much to handle.”

So here is the updated “design”.

They are still concerned about keeping the light balanced and not too heavy in the head, but if you have some more ideas to improve the design please post them up.

Another idea is to continue the grooves around the back side of the switch to give more surface area. You lose a bit of mass, but maybe it’s worth it?

The L6 has grooves all the way around, but much shallower. The S70 only has grooves on two sides.

I don’t know if it’s an idea worth pursuing.

I don’t think this diagram is very helpful.

This is not how heat transfer happens, there is no linear projection, no guided cone.

Heat sinks by conduction towards cooler material in proportion to how much cooler it is and how good a thermal conductor it is.

Now in this case we have one uniform material, aluminium, so the thermal conductor is identical. Other materials in the design are to all practical purposes irrelevant.

So heat will flow through the cross-section as if the aluminium were a raised concrete surface and you were pouring water on to it from the position of the LED. Heat cannot escape to the air very fast, so consider all the outside edges to have a retaining wall of fine mesh through which the water flows slowly.

The aim is to keep the water from rising close to the LED.

The greater the length of outside edge the faster the water can escape. Fins good!

The higher the water rises at any point the faster it pushes through the mesh at that point.

The narrower any passages are, the less effective the loss through them, as there will be a build-up of water height at the source side to push through the narrow passage, and thus the height at the fin side is reduced, and the less water pushes through the mesh around the fins.

I think this is the most effective way to visualise it. I can’t produce a diagram like that though.

Another idea: maybe the first fin on the front part of the head could be moved to the back part?

The beefing up of the area near the led will help, also as a simple heatsink that will extend a turbotime.

Something else, but it will change the shape of the head and thus the aestetics: if the fins at 2) are enlarged outwards as wide as the fins at 1) you will end up with a couple of actual decent fins that are reachable for the heat because of the now thicker material in between led and fins (let’s hope that the threading does not spoil it too much). (and not rounded like the plunger option that most did not like, but straight, more Luckysun D80 style)

About the balance, I do not see where to remove a lot of material in the head, so the most efficient way to compensate the balance is by adding weight to the other side: how about a cool massive SS tailcap that will also match nicely with the SS bezel? :sunglasses:

No. It is not proof that there is “very high” thermal resistance between the LED and the fins.

It is proof that, unfortunately, thermal path to the switch is rather good though.

The fins and head will heat up more slowly because they are, at their extremes, much further from the emitter, have greater mass, and can shed more heat more quickly.