Hi all,

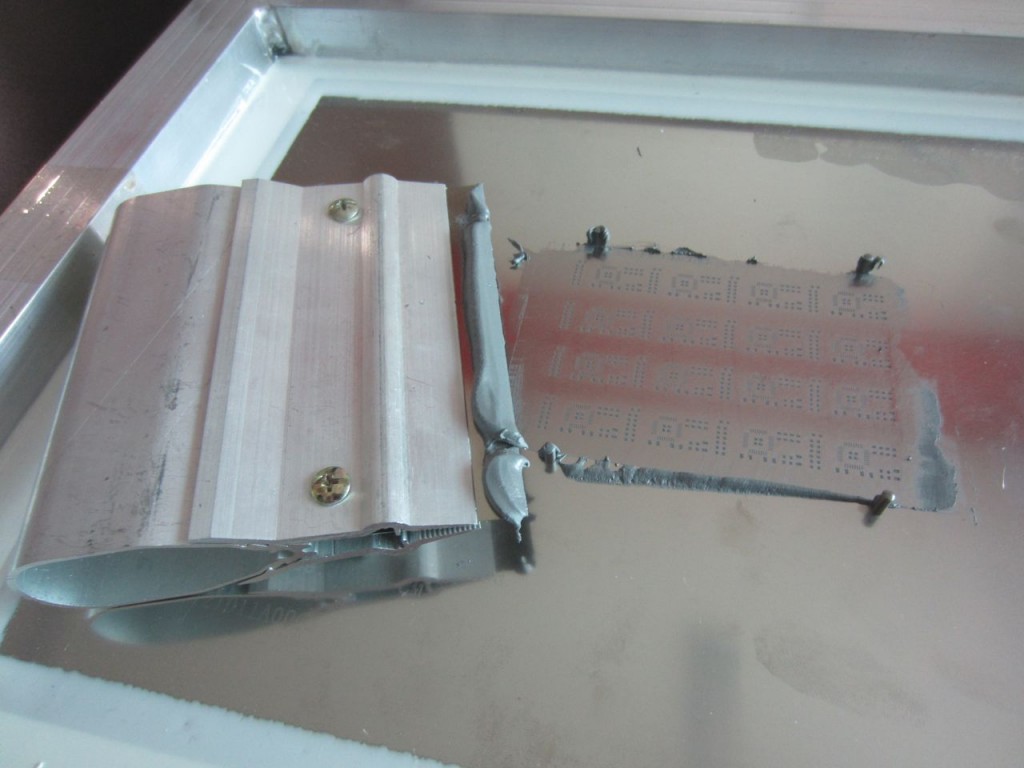

I need to reflow solder a large number of LEDs onto frames of mcpcbs. I have ordered stencils to do so, tried both the plastic and stainless ones but I still have some major issues. The LEDs I am working with are very sensitive to any imperfection in the thermal or electrical path. When I reflowed these individually moving the LED around to spread the solder and then pressed down on the dome to squish out the extra almost every single one I ever did worked perfectly. Failures were negligible. Sadly moving to the stencils I get about a 30% failure rate on the LEDs.

What I think is the problem is inconsistency with the paste. It seems like a large number of the failures have just slightly less solder under the center pad. I did also find a few where the LED did not sit down all the way or was not level but more of the first. I use kester EP256 solder paste.

Adding to the horrors of doing this project is that all of the LEDs must be viewed under a large aspherical lens so they need to come out 100% clean and neat hence the further need to get away from the individual method because of all the clean up.

My questions.

1. What do you think could be causing this issue? My technique? Equipment? etc…

2. What solder paste should I be using? Does it come in a bucket I can use a putty knife with?

3. What thickness of stencil?

4. Should I be getting framed stencils?

5. Would this help? https://www.ebay.com/itm/CYBRES-SP2421-Manual-Stencil-Printer-SMT-Schablonendrucker-/252416551098?\_trksid=p2385738.m4383.l4275.c10

Thanks in advance!!!