EDIT: here’s a brief TL;DR to help people just reaching this topic avoid having to wade through it all:

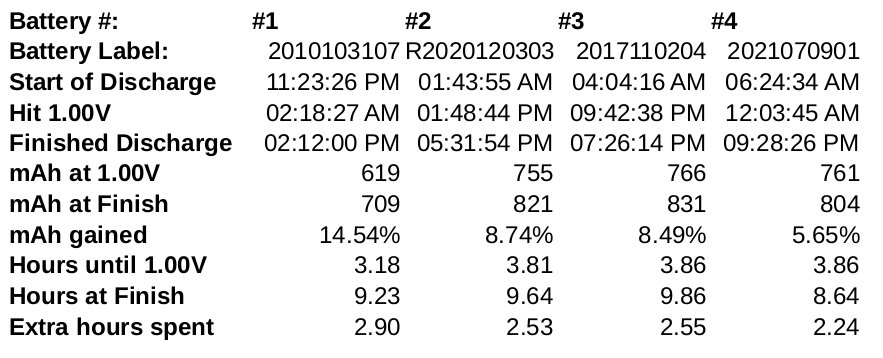

On Eneloop/NiMH batteries, the MC3000 unexplainably takes in practice a very long time (twice as long or more) during the discharge phase of the refresh operation than it theoretically should (it should stop at CUT VOLT), but whatever it’s doing, is not harming the batteries: we can see their capacity keeps improving after repeated Refresh operations. So the best approach as a user seems to be the BOHICA one: just be patient and endure the extra time and wait for the MC3000 to do its thing, because it apparently knows it better than us.

Original post follows:

As per the subject: during a refresh operation, the charger spent almost 9 hours(!) in the discharge step of the C>D>C cycle, until I aborted the operation, and almost 6 of these hours were spent with the battery voltage hovering just above 1.0V and the current switching between 0.00 and 0.01A, here’s a video clip of what the display was showing: https://www.youtube.com/shorts/SNaWP0JV-v4

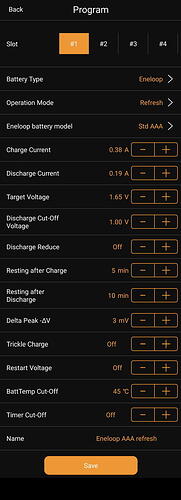

Here’s the app screenshots of the program I used for this operation:

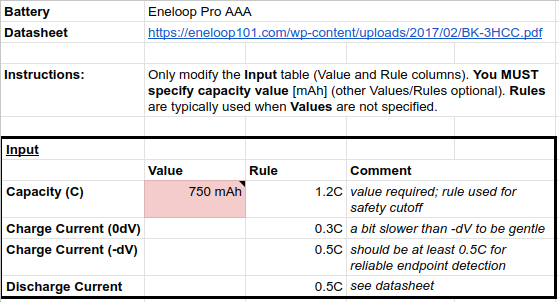

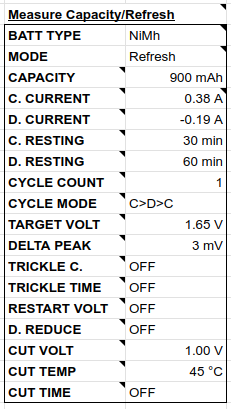

Here’s the relevant parts of @SYZYGY’s “Ultimate Program Guide” for the MC3000:

As you can see, I set everything in the app’s program exactly the same as recommended in the spreadsheet (except the battery chemistry, which I changed from “NiMH” to the more specific “Eneloop”).

I’m aware that the MC3000 (depending on the “Delta Peak” parameter) can have issues with NiMH charging, specially with old batteries and depending on the DELTA PEAK parameter, not discharging – so I’m really stumped on this one.

I have 2 main questions:

-

Can any of you see any mistakes or omissions in my program?

-

Has anyone ever seen anything similar?

TIA!

EDIT: more details: the charger is the new model with “knobbly” contacts on the battery terminais and 2 fans, and its GSV shows “HW Version: ≥ 2.2” and “FW Version: 1.18”. I control all operations exclusively using its Android app, which is version 3.95 (latest AFAIK).