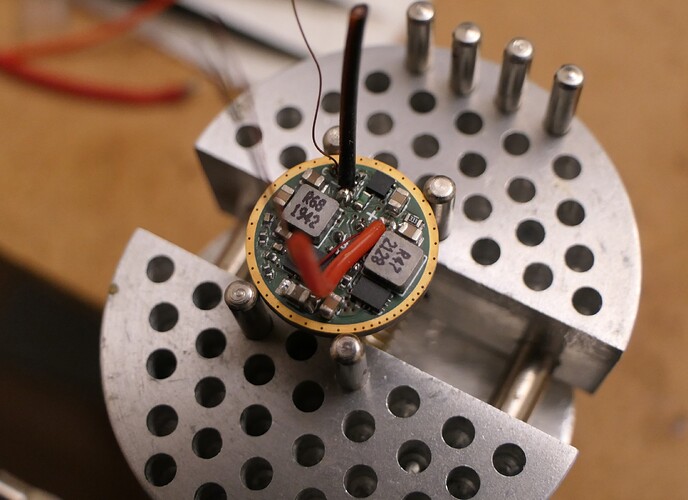

I finished assembling my FW1AA with NiMH/li-ion boost+buck driver, a dedomed 519A and aux LED :

I tried using cyan+warmwhite+pink, I think I prefer the good old RGB though.

FWAA 219C sliced with boost driver vs FW1AA on li-ion :

1501cd vs 5675cd

670cd vs 3150cd on NiMH

I find the beam of the FW1AA much more usable.