Big screw clamps reflector to pcb from backside.

Reflector openings are 6.5mm (according to the drawings from CAD files that were shared by Miller).

Big screw clamps reflector to pcb from backside.

Reflector openings are 6.5mm (according to the drawings from CAD files that were shared by Miller).

That big screw does not much, except fixing the ledboard to the reflector, in the first run it probably helped fixing things in place during assembly to prevent shearing off leds. It is something that Thorfire came up with, it was not how I designed it in the first place and we just left it because we could not see harm. And now it comes handy to fix the whole thing with the washer if the small screw holes are left out. I think that will work fine without twisting becoming a problem.

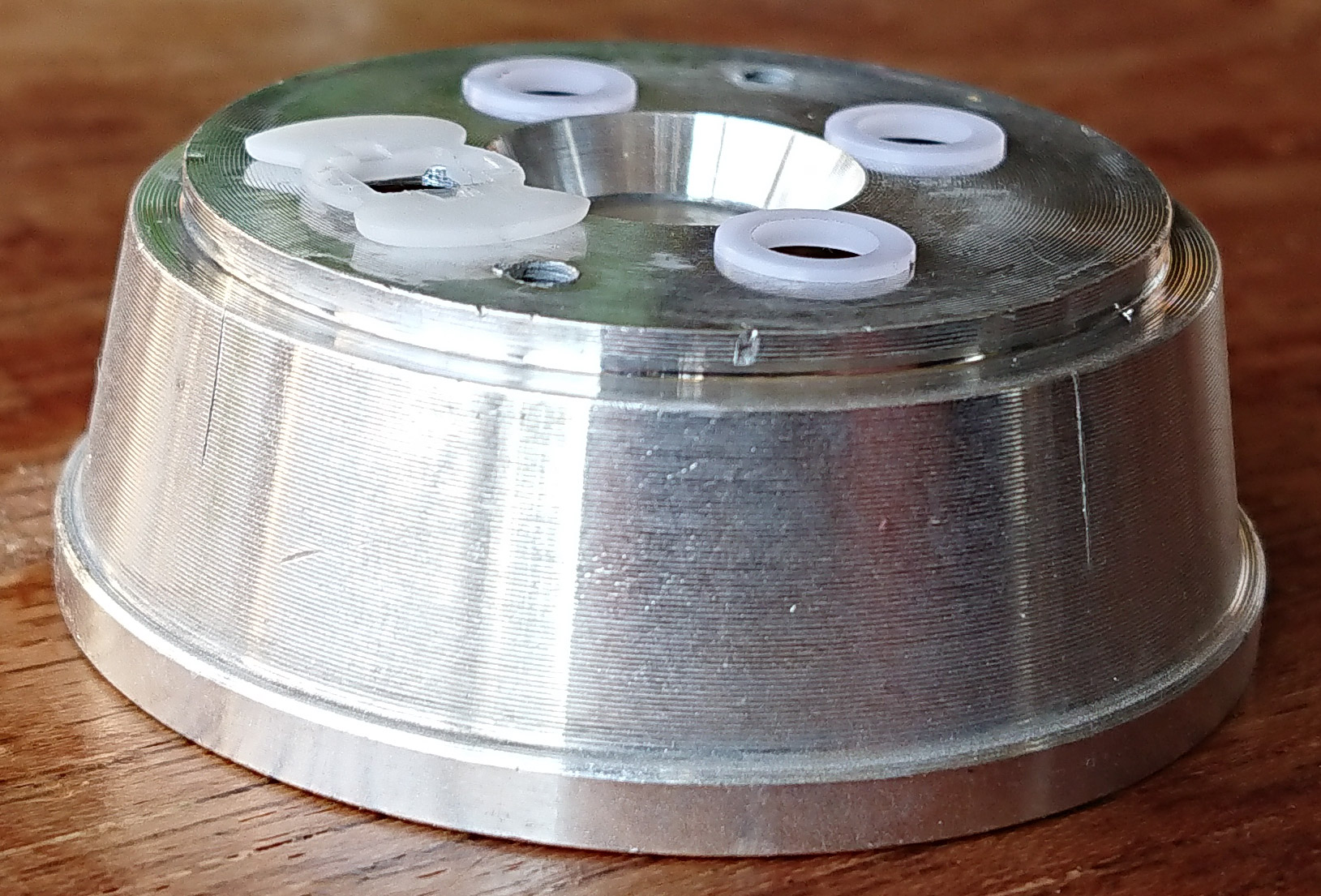

The reflector base is a bit wider than the cavity in which the MCPCB sits. That cavity is 2.2mm deep, so the 2.0mm board is sunken in by .2 mm. The base of the center pieces is .5 mm, so you have .3 mm room to play with, a bit less because the reflector is clamping on the centerpieces, squeezing them slightly I guess. In any case, you will not get away with a 1.55mm MCPCB.

I guess no one has checked the fitment of XM-L leds before? I just did: by just a bit a XM-L does not fit the reflector holes. But the fix is easy if you have a reamer (a few dollars on Banggood gets you a reamer thst does this job fine).

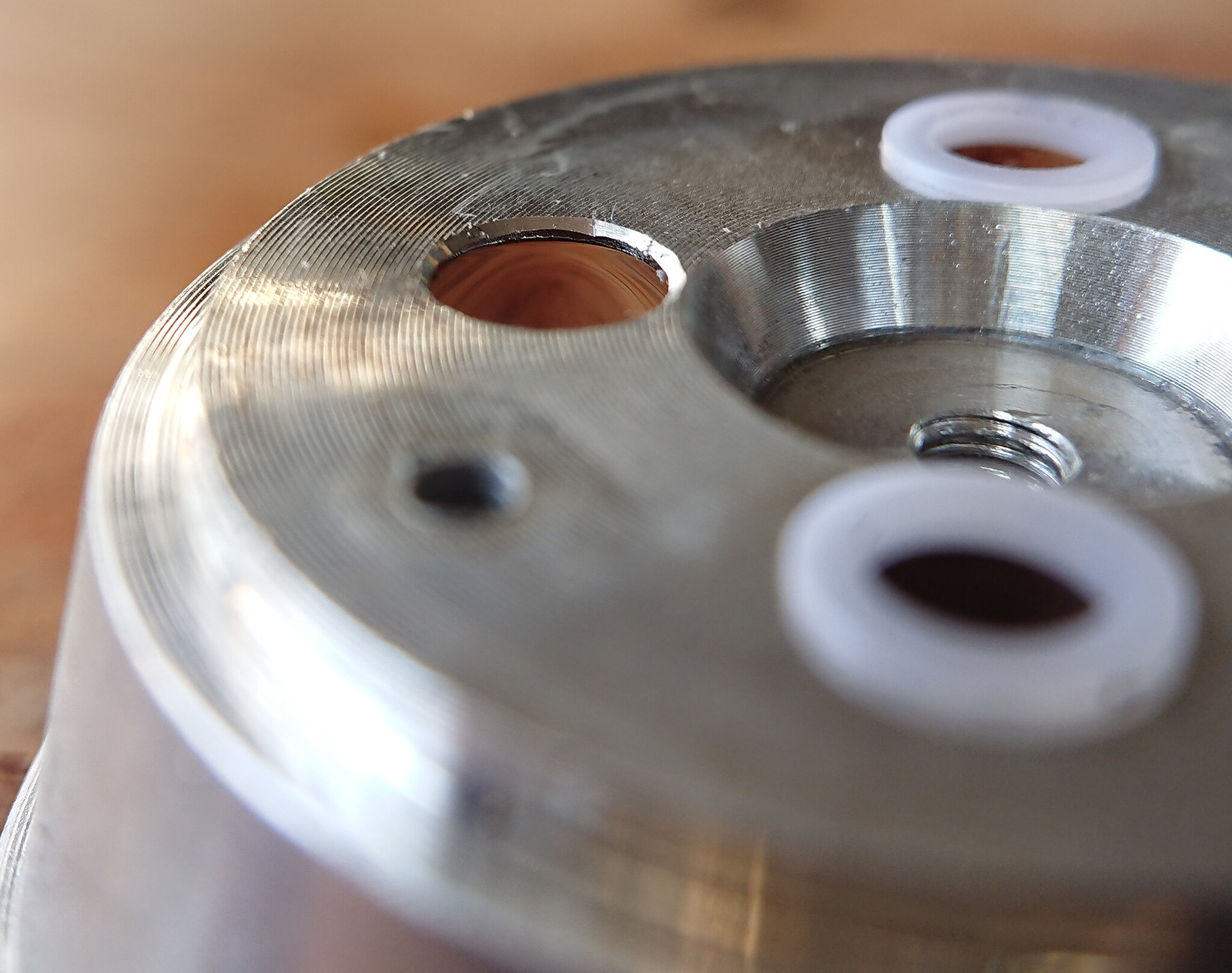

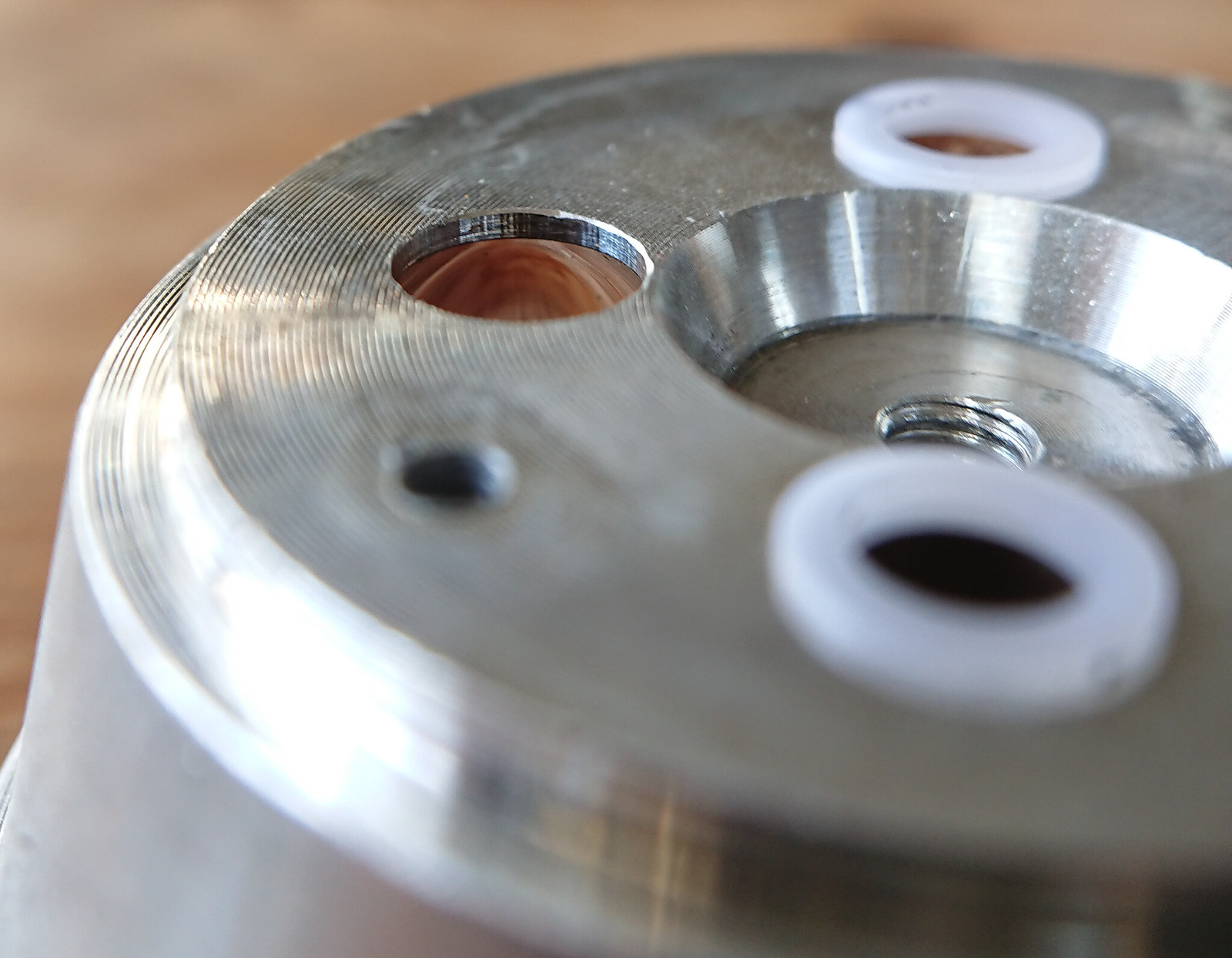

This is the stock reflector opening that does not fit an XM-L2:

Some light reaming makes it look like this:

Now a standard XM-butterfly centerpiece fits and the reflector is XM-L2 ready.

Buck drivers ready

What is the size of central screw,and what washer dimension would be optimal?

If others don't have anything against, this could be solution, which means boards will not have 2 smaller screw holes.

No one has tried this solution yet, will do some fiddling and come back to this…

Ok, I hacked something together. I figured a washer would require making extra holes for the wires anyway, so I made it a piece of aluminium 35×10×3mm with a 4mm hole in the middle, well, not really in the middle, it was a quick hack :innocent:

The screw is M4, and from the back of the shelf to decently screwed in the hole in the reflector (there is a bit more than 3mm deep working threading in the reflector so you have some play) you need 16mm of threading (so the threaded part needs to be 16mm + the thickness of your washer/piece). In place it looks like this and I must say it works fine: after fixation like this, the closing of the bezel does not move anything anymore. But this was without thermal paste, that may slide a bit better. Still, I think it works.

Ok the white driver is for 4S only and one buck engine. The black driver is for 4S or 2S2P and 2 buck engines for more power.

For the Black one: Vcc and ground are the inputs to the driver. + and - is for connecting the batteries with 4S and for 2S2P its connected to Vcc and ground?

Whats the maximum current for one buck-engine? 8A?

4S is for original 3535 MCPCB with XHP35 and 2S2P is for 5050 MCPCB with XHP50, isn’t it?

Prices?

The only hard thing is to fix the tube on the head without rotating at the correct orientation to the driver and make a tailcap with carrousel-PCB

Do you have enough space over/between the inductors for a washer or reflector-holder, like djozz showed?

Yes, I think that the single mounting screw is the best idea. It is simple and works. There is no worry about the assembly spinning as the wires can spin freely in the center hole without binding.

Looking forward to this project coming to fruition. I’m planning on putting MZ 90CRI 3v 5700K leds in my Q8.

In most cases it is not real. Q8 threads are not synchronized with driver screw holes.

This decision is not safe. To make it more durable, you need to add extra pcb and fix it on the tube, and change driver pads to the design that allows rotation.

A driver with pads that allows rotation are a different driver design as shown.

I have 2 Skyray King with similar designs, as you can see here:

But with the design of lexel (and others of cause), we need a tailcap-pcb which allows rotation and the tube has to be fixed to the head at the correct orientation.

This is how board will look, it's based on djozz' measurements. I'm sending gerbers to factory tommorow.

If anyone sees some kind of error, please report.

Any need in back plug to hold cental screw?

Looks good to me.

What does the final price work out to? I think I will have to grab a few of these myself.

@ kiriba-ru - yes,something like djozz showed, I will check if there is off the shelf solution for retainer.

@TA - prices are the same as in post #91

But that was like a WHOLE month ago, you really expect me to remember that far back? lol :confounded:

I confirm my interest for 2 pcs.

The battery Tube of the Haikelite MT09R fits the Q8. Haikelite wrote that they want to offer a 8-battery tube.

I have asked Dale from Haikelite, if it is possible to buy the 2S2P tube separately, but he did not answer yet.

Is someone else interested in the 2S2P or 2S4P tube? With more interested people the chances rises that we can buy it.

I think this thead is the best to ask about it. The more people know that there is a fitting 2S tube, the more would buy the 5050 MCPCB for a XHP50.2 Mod.

The battery Tube of the Haikelite MT09R fits the Q8. Haikelite wrote that they want to offer a 8-battery tube.

I have asked Dale from Haikelite, if it is possible to buy the 2S2P tube separately, but he did not answer yet.Is someone else interested in the 2S2P or 2S4P tube? With more interested people the chances rises that we can buy it.

I think this thead is the best to ask about it. The more people know that there is a fitting 2S tube, the more would buy the 5050 MCPCB for a XHP50.2 Mod.

Good news sofar!

I do not have a MT09R, would that 2S2P and/or 2S4P tube require modification to the Q8 head so that connection to the Q8 driver (or the 2S Lexel Q8 driver) is correct? If it is not too challenging I’d love a 2S2P tube. For me the 8-cell tube on the Q8 would look awkward and makes the Q8 so big that I would not use it.

Interested