Hey all. I use a spare soldering iron for reflowing. It’s worked well. But I’m considering a hot air rework station for other more challenging boards and integrated circuits/LEDs. Can anyone offer advice or guidance on what to get or how to use it?

From my research, in ascending price order:

858D and clones. Pick a clone with good reviews and check for loose connections. Should run $40-50

Quick 957DW+, $100-ish

Quick 861DW, over $200

Any more info on usage etc? I’m perusing a few on Amazon Canada.

I'd highly recommend getting the right tools to use with your hot air reflow system; it'll make your life a lot easier.

- Something to hold your PCB, which is also heat resistant. I'd recommend something like a 1.5" / 2" / 2.5" toolmakers vice, or any small vice to hold your PCB firmly while doing the rework. https://www.amazon.com/HFS-Precision-Toolmakers-V-GROOVE-0-0002/dp/B00NG08TAE/

- Flux - you'll likely be reflowing a bunch of parts, I'd recommend something like this, it will make your life a lot easier: https://www.chipquik.com/store/product_info.php?products_id=310004

- Small brush and isopropyl alcohol to clean off the flux after reflowing

- Solderpaste - useful to have, or you can just pre-tin the pads with a soldering iron... with experience you'll know how much to put

- Needle tweezers - pick up a set of good ones; they'll last forever if you take care of them, and they're pretty cheap too

There are lots of cheap options from Chinese manufacturers for reflow irons... if you can, I'd recommend spending more to get a good unit that will last many years. Otherwise, for more budget options, I've had decent lucky with YiHua products: https://www.aliexpress.com/item/1005001894899802.html

I'd recommend playing around with the different nozzles, temperatures and flow settings to determine what works best for your particular hot air system. With experience, you'll figure out what setting to use for different jobs. One good way to practice is to hand solder (with a regular iron) some pads on a random PCB you don't mind messing with. Then clamp your PCB onto your vise (or some heat resistance surface), and slowly heat up the surface (there are a bunch of youtube videos on how to do this). You should be able to see the solder begin to melt and then reflow.

Here's one from EEVblog... not one of his best videos since it was made so long ago, but you'll get the idea: https://www.youtube.com/watch?v=M_rO6oPVsws

Experiment with different components and flow settings to make sure you don't blow your component off the PCB. Flux on the surface helps a lot.

Finally, use 63/37 leaded solder, not 60/40, not lead-free. You can progress to those when you have more experience. 63/37 is nice because it has a very narrow temperature range turning from solid to liquid, unlike 60/40 solder. Lead-free solder doesn't wet as well and typically needs a higher temperature, which can easily lead to burnt boards or damanged components when you crank the heat up.

Good luck!

Choose temperature and airflow and make things hot ![]()

![]()

I have a Yarboly 858D. Not obvious feature: When the gun is on hook, station switches it off. Very nice feature.

Needs lots of experience to choose good parameters:

Extensive review by David Jones:

Thanks all! I’ll take a look at those links!

I have the cheap 858D and it works fine, if you only use it seldom.

I usually heat LED-Boards from the other side so that the plastic case doesn’t receive damage.

For Flux - I use the “Kingbo RMA-218” - you can get 100g of that on AliExpress for under 10$ - it is fantastic and acts like the very expensive Flux that Louis Rossman uses.

I would love to have the Quick 861DW - but since I only use that 30$ Reflow Station a couple of times per year - and mostly just to shrink heatshrink, there is no legitimation to spend close to 300€ for it.

I ordered this https://www.amazon.com/gp/product/B006FA481G/ref=ppx_yo_dt_b_asin_title_o07_s00?ie=UTF8&psc=1 and have been super happy with it. No issues, and I use it daily. Another hobby of mine is RC cars/boats so I am always soldering xt 90 battery connectors, and they’re quite heavy duty and this doesn’t have any problem doing anything i’ve thrown at it.

-Bryan

I use the Quick 957DW+ ordered from Tequipment . Price is decent in CAD$ and Quick is one of the better Chinese companies producing soldering equipment. I use it mainly for building drivers, setting the temp around 230C with leaded solder paste and the airflow at about mid setting or a bit less. Sometimes I use it for reflowing leds but prefer using a hotplate still. The temp needs to be a little higher when using the hot air for reflowing leds because the copper board is trying to do its job of course. Main thing is to not use too much solder paste (esp with the drivers) and to keep the air flow moving as to not damage anything. Also this little vise from Amazon is a huge help and only cost $20CAD.

I actually used the 957DW+ professionally. We modified ours to use NEMA5-15P to C13 power cords by wiring a socket into the backside.

I’m very happy with the Quick hot air station. It’s very well built compared to my previous Yihua 2 in 1 and used by many professionals to my surprise.

Oh yeah? That’s really cool to hear. I’m just wrapping my head around spending $121 Cdn. I think I spent a similar amount for a decent soldering iron.

I have a round pin vise attached to a table top tripod I like, but it can mark up delicate finishes since they are stainless steel pins. Like this https://www.leevalley.com/en-ca/shop/tools/workshop/workbenches/vises/31175-jewellers-pin-vise?item=60F0501&utm_source=free_google_shopping&utm_medium=organic&utm_campaign=shopping_feed&gclid=Cj0KCQiA0MD_BRCTARIsADXoopbpO-oxcZYAE-nbjGxq-CXS5LJC8theZtPlTpYq4u6xzLE7UsnmoicaAjolEALw_wcB

Mulling.

I also considered buying that vise with the pins and somtimes still want to because it looks so cool but I probably don’t really need it. It will actually work perfectly for you I’m sure and I’ve seen others use it for this purpose, particularly for boards. For example vestureofblood uses it and some of his videos. When reflowing leds onto copper boards with hot air (and you might already do this when soldering with the iron) , I suggest only using the pins for support and raising the board off the surface so the precious heat isn’t lost into the body of the vise. Last thing. Tequipment has really good prices for Hakko C.H.P flush cutters and pliers. The flush cutters are something like $6 or $7 CAD and most of them are made in Italy as well as some in Japan. I ordered a variety of those to offset some of the shipping costs.

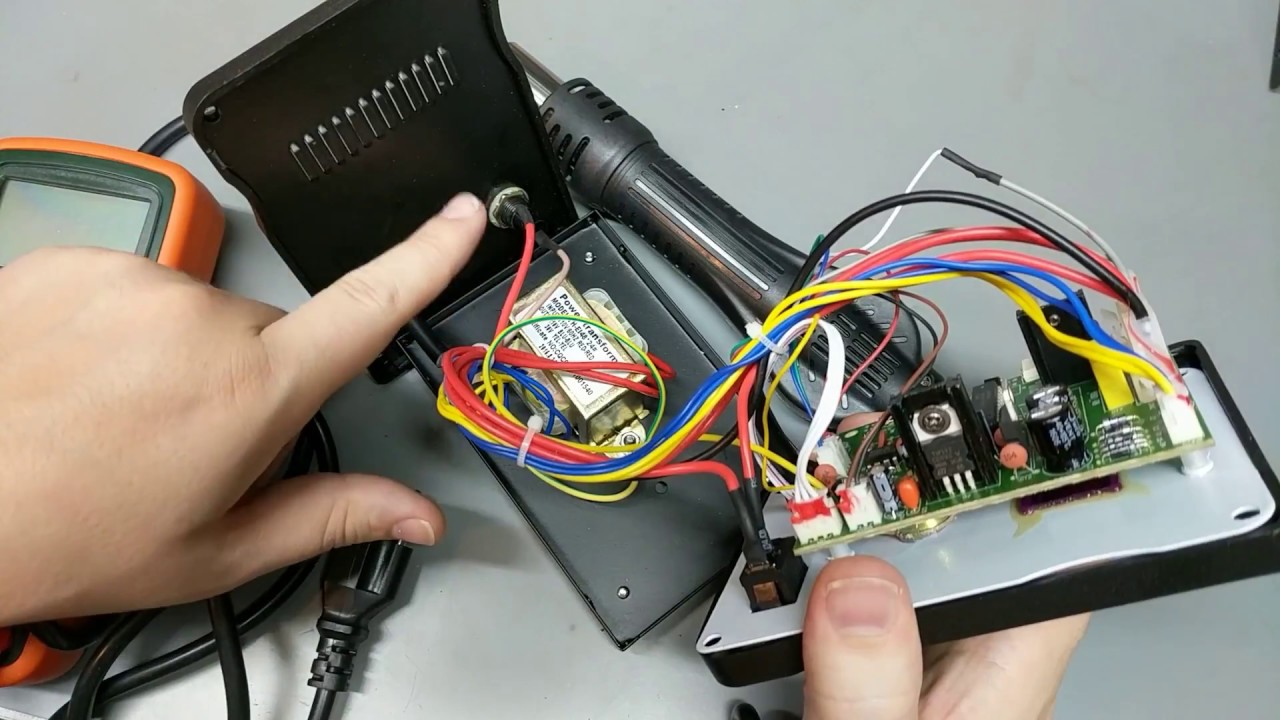

Be careful of cheap unbranded /clones of Yihua 989d+ and others. There’s a slew of checks you need to do to ensure your equipment is safe to handle. Some of them have reversed neutral and live and may not be properly grounded. Mine arrived with neutral/live shorted because mains were swapped around in the wrong terminal.

Thanks. I read about that a bit. Perhaps buying the quick would just be a safer bet? Is it really useful? I never thought about it much but sometimes I can’t get good access to the back or the board is populated with components.

This is what am been using for 2+ years for reflowing, board components removal and installation and I even built 3 old school hot wire regulators with it.

Bunch of accessories and spare heat element which is still OK.

Can't beat this one for sure

Like I said earlier. For reflowing leds, I still turn to the hotplate. For building drivers from Oshpark or Mountain boards one could use either but I prefer the hot air station; simply because it’s easier to control what’s going on with multiple components. For modifying prebuilt drivers or repairs, especially with the tiny smd components used lately, the hot air can’t be beat. It’s easy to use right away without any practical experience but I’m still no master. For example, I really want to change out the xpl-hi leds on the lux-rc v5 triple in my BOSS but THAT I haven’t had the guts to do yet. So is It absolutely necessary to have a hot air station? IMO no, but it is a useful tool that opens up a few doors which makes our hobby more interesting.

I guess no one here follows Louis Rossman…

I get that the Atten and the Quick hot air units are “expensive” but they really are the best units on the market. The other big names like Hakko and Weller are just rubbish in comparison.

We have the Quick 957DW+ at work. I recommend.

Quick 957DW+

I have the Quick 861DW at home. I recommend.

Quick 861DW

I also recommend TEquipment.