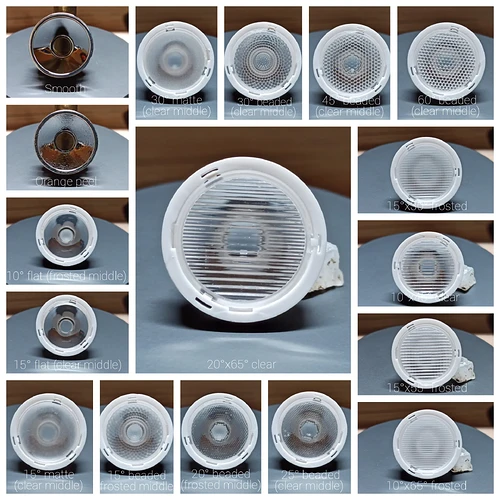

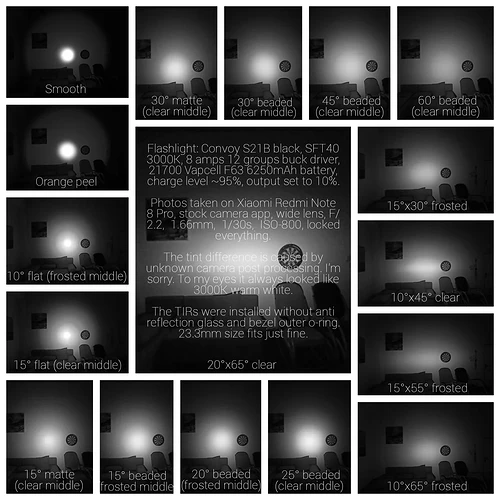

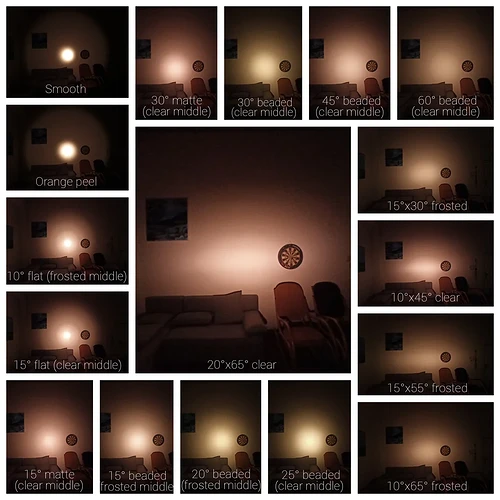

Credit due to user Kai_159 on r/flashlight; here’s the post. Huge thanks for taking and labeling these photos, and for the permission to share this on BLF–I wanted to do this given how difficult it is to search reddit.

Great googly moogly, this is incredibly useful. Thank you for posting this.

Nice!!

Recently I got an 15 degree beaded and was surprised with its beautiful look!

Now I don’t need to buy ALL of them to check (:

Exactly the sort of stuff I needed this for! I found out from other sources about the 15 and 30deg optics having a sunflower diffusion pattern, so I got them and couldn’t be happier. The 30deg, in particular, might be my favorite right now: good flood, usable throw, no tint shift. Incidentally, I believe the same optic is being used in some Skilhunt lights.

And as we see from the beamshots, the nominal angle often does not correlate with the actual beam shape!

Has anyone noticed that with the 21mm variant the tir itself sits directly on the corners of 5050 LEDs?

I suspected the white housing with its square opening to act like a gasket, spacing the tir just right not to exert any force onto the top of the led when screwing down the bezel. But after test fitting one onto an SFT-70 on a 16mm MCPCB I noticed that the bottom of the white housing doesn’t even touch the MCPCB.

Here’s a reddit post that shows a damaged XHP50.3 HI probably because of that issue/design error: https://www.reddit.com/r/flashlight/s/gftCIhd9eW

This comment mentions sanding the bottom of the tir in order for it not to sit on the LED and to just overall fit better.

I’ve also seen @QReciprocity42 use a 9mm 5050 gasket in combination with the bare tir, would that be the most elegant solution to this problem?

Thanks for bringing this up! I currently EDC a S2+ SFT70 with the 30deg beaded variant of this TIR, and did run into this issue of TIR sitting directly on the corners of the LED. This is certainly not good, but didn’t cause me any real issues aside from a tiny bit of initial plastic dust. It’s not nearly as bad as Convoy’s circular-opening centering gaskets grinding on the LED corners–in this TIR situation the TIR rests on top of the LED corners, which are much less sharp than the sides of LED corners, but this would obviously be a problem with softer LEDs like XHP50.3HI. I might consider cutting away some corner silicone with a hobby knife beforehand.

But a carefully-shaped 9mm square-opening 5050 gasket does take care of this problem to a large (if not full) extent. If you’re using a non-diffuse TIR and a tiny emitter, you might run into focus issues due to raising the height of TIR, but given that the stock 10deg clear optic already suffers from focus issues (reflecting surface deviating too much from a smooth curve), it’s nothing to worry about.

With an SFT-70 I wouldn’t worry that much about it either (although it still feels kinda wrong) but I want to put the tir in my S21e with an XHP50.3 HI, so I’d like to do it the “proper way”.

I thought about just adding some spacery things between the housing and the MCPCB to lift the tir ever so slightly off of the LED. But when screwing down the bezel, any twisting could still damage the upper silicone layer of the LED since the cutout of the housing doesn’t reach down to the ceramic substrate (I think).

What do you mean by “carefully-shaped”?

Sanding down the ring that normally centers the reflector?

I have the 30° beaded since it looks really pretty and you kinda hyped it up for its nice beam shape and tint blending. ![]()

So I don’t worry as much about proper focusing as I do about light going directions it shouldn’t and thus lowering the transmission efficiency when raising the tir to high.

I see about your concerns with the XHP50.3HI, the soft silicone is easily damaged.

I noticed that the production process for the centering gaskets has changed since my batch (from year ago), the current gaskets are slightly different in shape and worse in just about every way. In response to this, I will offer the following:

- First, try to use the gasket without modifications (aside from possibly carving the bottom to make space for solder blobs to the side of the LED). If the TIR (removed from the white holder) already sits inside the gasket’s circle in a stable way, no more modification is needed.

- Otherwise, grab a hobby knife and gently ream the inside surface of the raised circle/ridge on the gasket. Try to the fit TIR again, and if it doesn’t fit, rinse and repeat until you’ve reamed the inner diameter of the circular ridge large enough to fit the TIR stably.

- On the off chance that reaming reduces the TIR’s height so much that it scrapes the LED again, pad the bottom of the gasket with some sort of hard tape.

When you twist the bezel, all the torque will go into making the TIR rotate against the inner surface of the gasket ridge, which exerts no pressure on the emitter.

Incidentally, this is the same method I used to center a T3 reflector (5mm diameter opening) around a 5050 LED (7mm diagonal).

Very nice! I find this specific optic to be particularly good at fixing emitters that are on the green side, so much so that I would not use it on a pink emitter to avoid making things unbearably pink.

I suspect that transmission efficiency will be lower for XHP50.3 compared to SFT70 due to the much larger LES producing more stray light, but it’s nowhere near as bad as a large domed LED like 519A in a Carclo triple, which probably loses on the order of 30% of collected light.

I’ll probably try the spacer approach since I don’t have these particular gaskets on hand and don’t want to place an order just for them. I’ll let you know how I did it when I did it.

That’s some valuable information still, because I’m planning on fitting an XHP70.3 HI into an S2+ without sanding the reflector (much) to open it up but to instead also try to center it using the inside of the gasket’s circle. I’ll probably open a dedicated thread/topic when the time comes.

Sounds like the perfect fit for my 5000K R9050 then ![]()

As long as I get somewhere around 90% transmission efficiency that’s fine.

Please keep me posted! I’d like to add this alternate solution to my repertoire.

This sounds feasible. Some S2+ reflectors have a conical exterior, while some others (usually smooth reflectors) have a cylindrical exterior that might not play well with this idea. Though in the worst case I suppose you can use a tool to reshape the reflector’s exterior until it fits inside the gasket’s inner circle. The 70.3HI’s emitting surface should be small enough to fit inside the reflector’s opening. I’d be interested in seeing that thread!

This estimate sounds reasonable with this combination. This optic is the right one for the job!