I would go with this option or even simpler. Most of us could probably make our own wiring harness to fit our own needs. A complete headlight harness with relay and switch can be bought off the shelf for cheap. Or go with a fancy wireless solution, if you like.

Trying to make everyone happy is pretty impossible so build the part we can’t and let us wire it to our needs.

Waterproofness will be a non-issue, I am expecting it to be something like IP69 waterproof. Durability also, the heatsink is pretty heavy itself with a thicker 4mm “guard” fin on each end. The housing will be around 10mm thick wall so it will be like a rock! hehe Reliability is likely dependent upon the driver, that is going to be the weak point, as everything else will be simply be bulletproof. As far as pitting and chipping, how durable is a high heat enamel paint? Not sure on that yet.

Cheers.

He might have been referring to the glass or poly carbonate on the front, chipping and pitting. Probably easily replaceable. I would have a vinyl cover made. If the light is sitting up high on roof rack, or a roll bar, I wouldn’t think chipping and pitting would be too much of a problem.

Was there a link to the Russian drivers that I may have missed? Just wondering how you would select modes with a rotary switch? When I first read modes, I was immediately put off because I have it’s so ingrained in my head how flashlights have to be cycled through ALL of the modes to get to your desired brightness. Two rockers and a rotary wouldn’t be too bad.

Oh, okay, well the lense would be 1/8” Makrolon AR Polycarbonate, which is abrasion resistant. Supposed to be very tough stuff.

Sorry killforfood, i missed your post, i will post a link later today.

http://www.ebay.com/itm/111949889657

There is the eBay store for the driver.

I will torture them in the prototype light bar to see if they are up to the task. If not, I will have to go TaskLED.

[quote=zpinch]

Some of those paints soften somewhat with heating. My first choice would be for an industrial epoxy paint or a catalyzed enamel like Imron. 30 years around paints here but my industrial paint work and knowledge are from a long way back, I do however know a man who is in the specialized paint business- his company designs and produces aircraft coatings mostly- so if you get stuck I can look him up and get a engineer’s recommendation for exactly what you need.

Phil

Wow, what can I say, thanks. i haven’t been picking my brain particularly yet on paint choice, but when the time comes, I’ll come to you for help if I need it. ![]()

I’m no expert, so maybe this is just inexperience talking, but would there be any benefit to utilizing a cowl on the top of the bar to force more air over the cooling fins?

Benefit, yes, needed, absolutely not. The heatsink on its own with only natural convection should be enough to allow full rated LED life, which is already more than anything a person can utilize for car lights. I will be torturing it soon enough regardless.

Cheers.

If it would help simplify things on your end, I would be interested in this as a diy kit too. Just order parts in quantity sufficient to get a good deal, and maybe post up a simple schematic. I would actually prefer to have the housing cerakoted since I have a friend that does that.

And the more I think about it, the more I lean towards the idea of just a simple spot/flood on/off interface. If natural convection will sufficiently cool, I see no reason for running at partial power level.

One question I do have that I didn’t see addressed was how you planned on running your wires into the housing. Are you going to use a grommet, or would a Deutch connector be feasable? I am assuming that you would be running two separate power/ground pairs to run spot and flood as individual circuits.

One final point I would like to discuss, do you have a current working relationship with the machinist you are working with? My parent company at work is a large scale fabrication shop, and my boss is a rigid light fan. I would be more than happy to talk with him and see what kind of price I could get you on the housings if you would like.

I will let you know Mr. Big, haven’t had too much time to think about it. I have a good relationship with a machinist yes, I will get a estimate from him soon when I know that will be the final ‘general’ design.

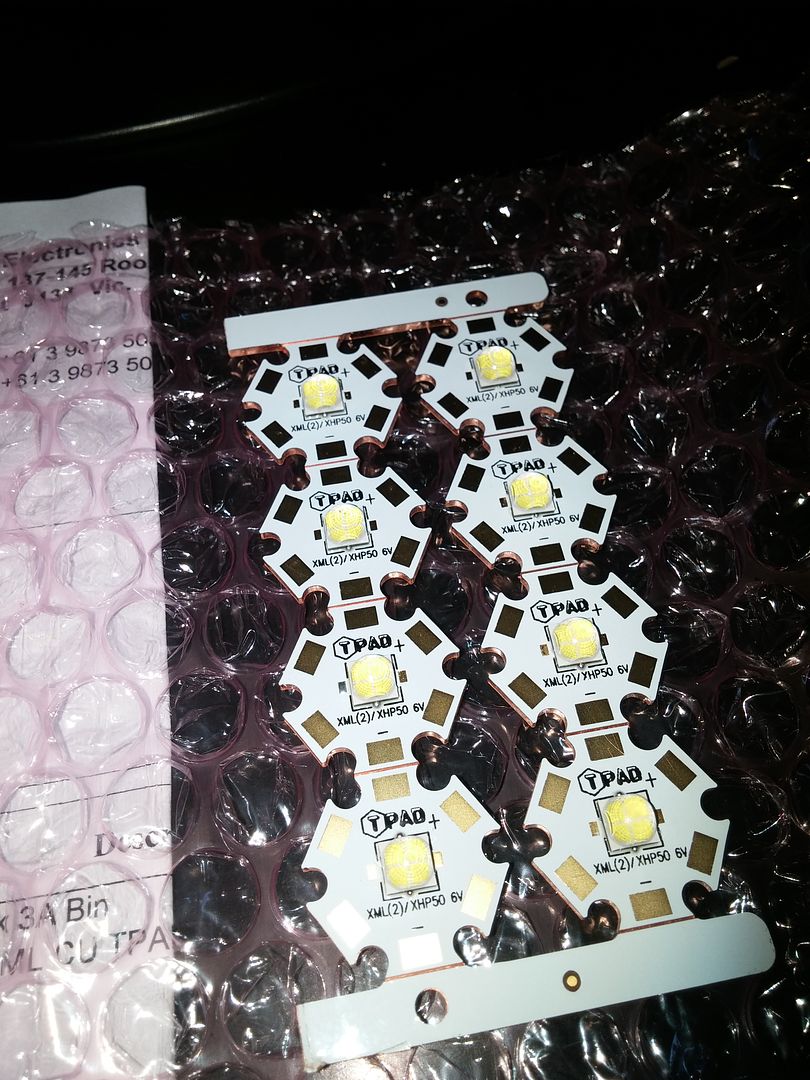

BTW, Cutter Electronics shot me an email saying they received a shipment of J4 (very top binned) 5000k XHP-50s, I ordered 8 LEDs last night, so 2 weeks they should be here. I also finally got Conrad to reply to my email and they shipped out the MF35-100 heatsink, they sold it to me for COST, $22 w/$56 shipping. The heatsink weighs in at almost 4 lbs (1.6 Kg), a very substantial piece of metal. Finally coming together.

4 Carclo Elliptical optics - Check

4 Gaggione Spot optics - Check

4 3A multi mode drivers - Check

Conrad MF35-100 heatsink - Check

8 Cree J4-3A XHP-50s - Check

Getting restless… check

Looking very nice! Can’t wait to see this take shape!

Looking good so far, it is nice to see a functional well thought out design come to fruit. One last thing have you thought about mounting a pressure port.

I have thought about a pressure port yes, IIRC, it was some other thread that a few of us were talking about it and thought it wasn’t needed or wanted. If the design is thoroughly sealed, that is. But that might change…

Now, trying to get a hold of Conrad heatsinks is like pulling your own teeth, I don’t know if the guy sent it or not. He doesn’t reply to emails, like at all, and the only way to get a hold of him is phoning, and that is if he picks up. They are the only company to make heatsinks like these, there is no one else. ![]()

Those are very top binned (J4) chips, good for 2500+ Lumens boys!

Had to make an account here just for this thread. I would be interested in buying one if you have a final result in the $300-350 range. It’s above any budget I’d have for it but it looks like it will outdo everything else in the market. An idea for “settings” could be a panel with three rocker switches, one master, and one for spot and one for the outer 2 flood LEDs. It’s only rocker switches so pretty simple and gives three options on output.

I showed the development here to a workmate, & he also expressed interest in one.

Thanks guys, and thanks Cameron. Cameron, the screenshot you see in the first page is not the optic configuration anymore, it’s 4 spots and 4 floods now with 20,000 LED lumens, OTF will bot be known, but probably 17,000 is a very conservative estimate.

I am oit of town, but i received the drivers and heatsink now, so just the spot optics i am waiting for. ![]()