I figured since I’m doing a lot of electronics projects, many led related, some not, I’d use this thread that started out as a thread for the repair of a single floodlight as a general “I post things” thread for my projects. Moved it to offtopic for that purpose.

You’ll see some electronic repairs, flashlight modding, and completely custom designed electronics in here eventually. Just posting whatever feels like fun.

Hope you’ll like it in here. Cheers!

My uncle bought some big 180W LED floodlights with 3 COB LEDs for his workshop a while ago. Not after long all three broke.

Upon inspection it was pretty clear - it uses one 20-48V 60A constant current supply, and 3 COBs in parallel with a V_f of ~30V, so 60W each. Paralleling LEDs that are not thermally coupled very tightly is already a no-go (although less bad for COBs), but the other issue was - whenever I looked up similar size and V_f COBs, they were 40-50W range, while here they are loaded with 60W. 60W is a best case estimate, it can be more due to manufacturing tolerances that amplify themselves. Hot LEDs have lower V_f, therefore get more current, therefore get hotter… Vicious cycle unless the LEDs are tightly coupled on a single MCPCB.

So I ended up buying “neutral white 75W COB LEDs” from China, without much more specs to go by. I wanted it to be cheap, since I was not sure the PSUs are still okay (no test load to try them properly, idle voltage was ok) and it’s not easy finding LEDs with these specs anyway.

I then forgot about the flooders and left the pack of LEDs in a drawer for some months, until I visited my uncle and noticed the crate full of dead floodlights in a corner. Decided to take them home and get working. Luckily my dad helped, so we were pretty quick with tapping new holes, cutting the “reflectors” larger to accomodate the larger COBs, and solder in new LEDs with a lot of thermal paste.

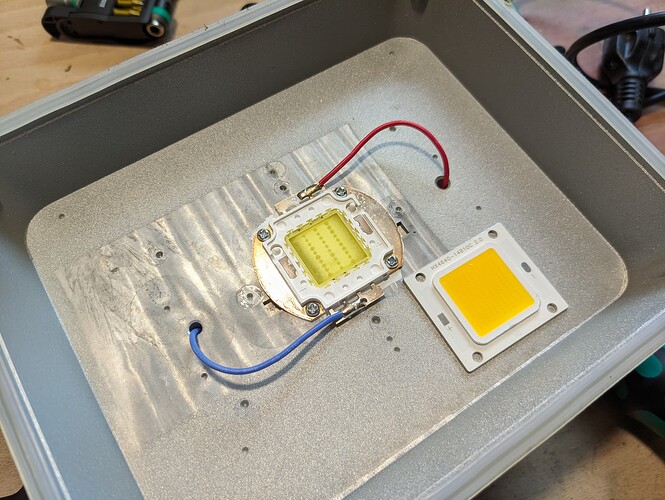

On this pic you can see the new LED, next to one of the old ones - note the size difference in active surface (spacing and size of chips inside the active surface is pretty much the same, can’t see on the pic).

Plugged it in and - to my surprise - no magic smoke! Man, those things are ridiculously bright.

Also, note the big cylindrical multi-led-lamp on the desk in the background… Different light for another day.

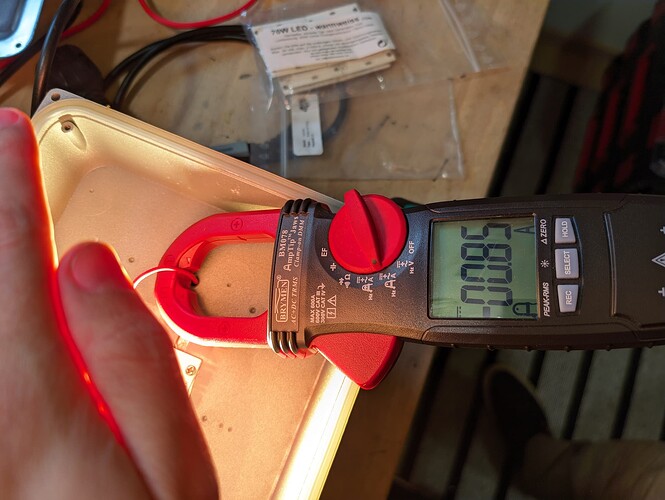

This would explain the brightness ![]()

We got ~225V AC here, so this is almost 200W. Leaves ~180W of power after the PSU for the LEDs.

We’ll keep 1 or 2 for ourselves (uncle already bought other ones for his workshop) and give him the others back to keep in storage as spares. These will make a great working-light in the garage.

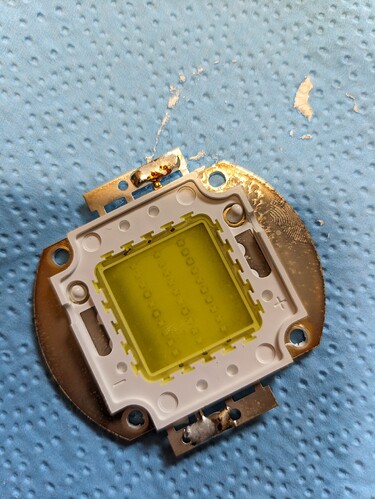

Bonus pic, dead LED:

The others had no visual flaws, but would not light up on my lab PSU at all, even up to 60V, so they must be somehow fried inside. 0A current draw on all of them. Maybe bond wires blown out? Do COBs even have such a thing? Dunno.