Finally finished my mod last night using this driver in a TangsPower Fing 5X, bought from TMART way back in 2014 here: https://budgetlightforum.com/t/-/26483. I'm so-so with the results of power/output, achieving "only" 14.66A measured at the tail, but with 50 7135's, should be 17.5A. Probably the bird's nest of wiring contributed to loss's. I had to use 22 AWG wires to the LED's because of reflector clearance space, then used 20 AWG off of the driver, all wires could probably use shortening as well. Here's some pics:

The 5X light:

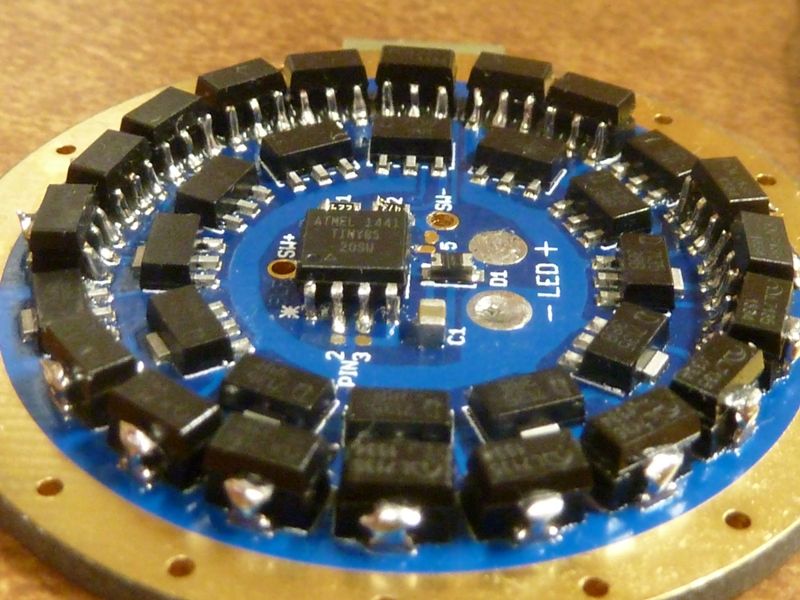

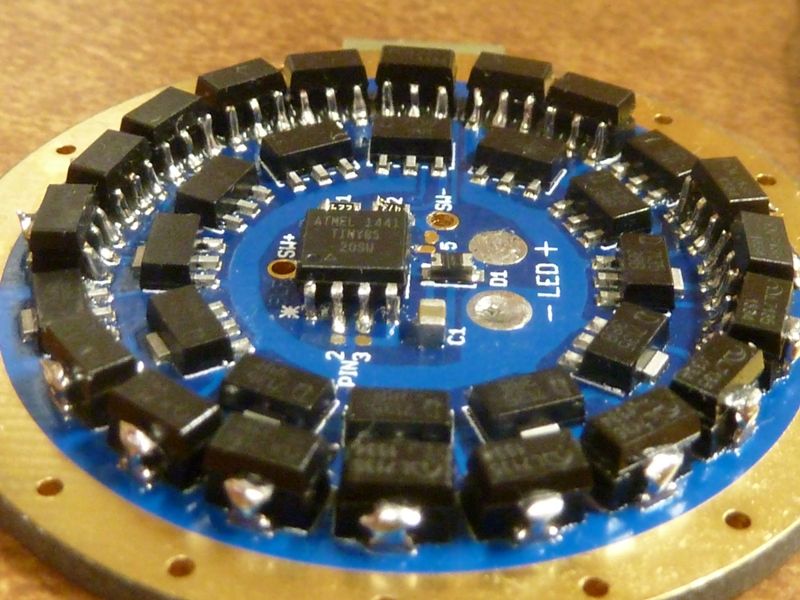

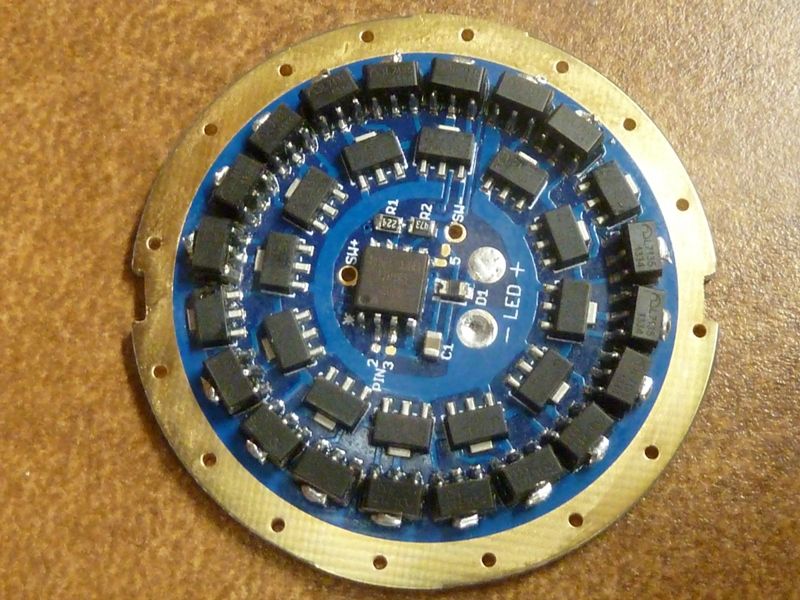

Showing the extra 18 stacked:

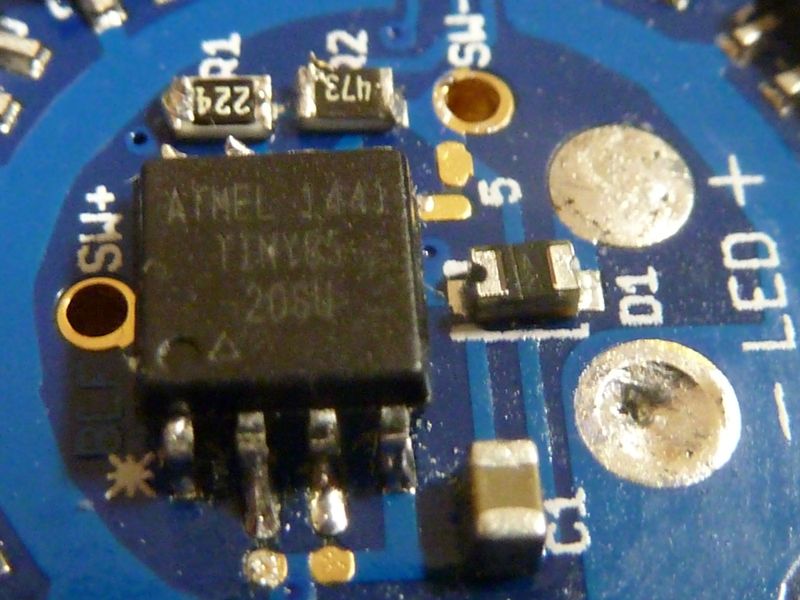

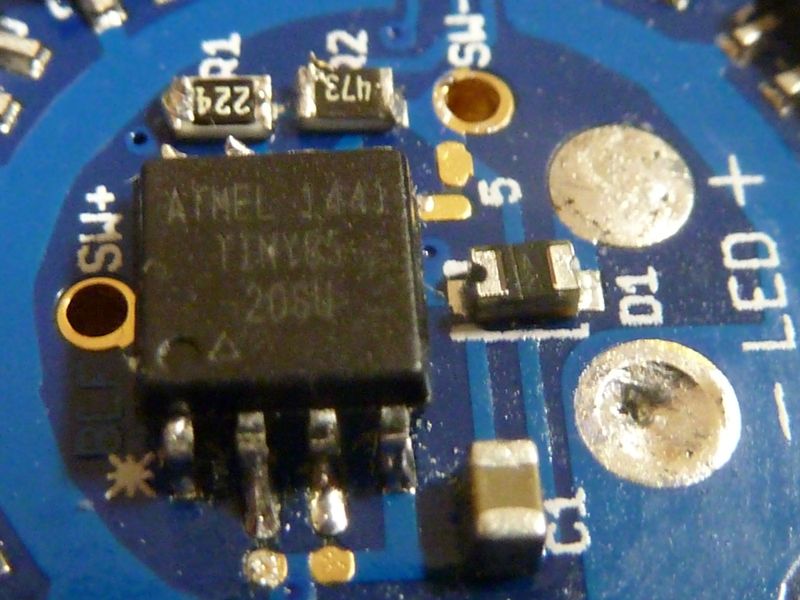

Here you can see the parts I swapped: Tiny85 for the 13A, and low drain voltage divider resistors of 220K and 47K:

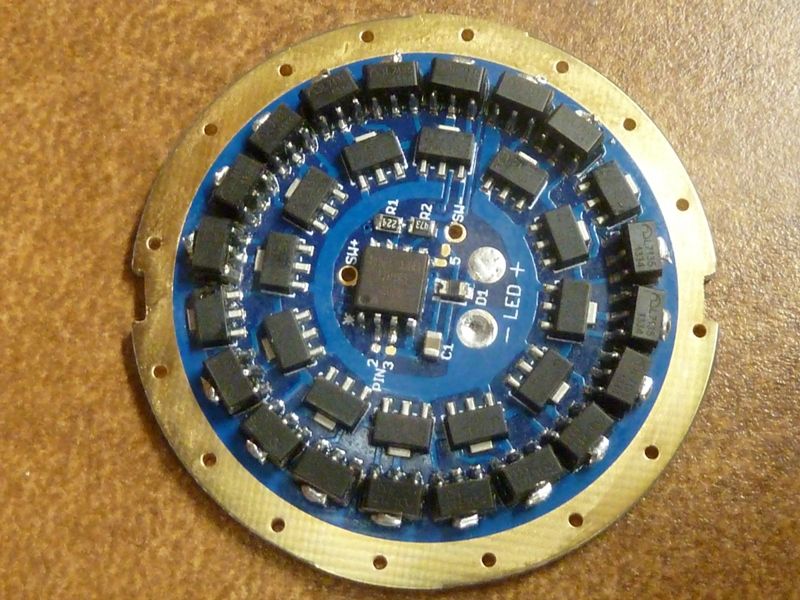

Here is the tabs sanded down, and the two notch's put in on the outer edge to help prying out the driver:

The birds' nest:

LED's mounted on the copper plate, made from 1.75" 18 gauge and 16 gauge copper copper rounds reflowed together, LED centering pieces filed down from stock size, a little:

So the good news is I didn't have to do anything to accommodate the Tiny85, like adding a cap or increasing the C1 cap. Of course w/Narsil and the voltage divider mods, the parasitic drain is extremely low, has a great lockout feature, and fully configurable modes. I found I had to raise the PWM value for moon mode to 5. 4 makes the LED's glow actually, but way too low for any use at all.

I should be getting in a UCLp in a couple days. Might just add a indicator LED using a light pipe, and see if I can reduce resistance, maybe by shortening up the wires, not sure yet.

For now, on SAM 30Q BT's @4.21v, 14.66A measured a the tail using a clamp meter (18 AWG loop built into the end cap), got:

lumens: 5134 @start, 4910 @30 secs, 41.4 kcd measured at 5m

This uses 4 U3 3D's, 1 U4 1C in the center. The UCLp should bump it about 5% or so.