2024-08-05

Update: Update to internal design of this LED (no round-die LED chip, but classic rectangular flip chip) here!

- Type: round die, domeless

- Bin: unknown

- Color group: unknown (3500 K)

- CRI: 96

- Rated voltage: 2.7 to 2.9 V

- Max. Forward current: “10 W”

- Max. Peak current: — mA

- Viewing angle: — °

- Thermal resistance: — K/W

- Max. Temperature Tj: max. —°C

Warning: An official data sheet and further information are not available for this emitter. Official data can therefore not be provided during the test.

The emitter tested here was kindly made available to me by TLF user @Palladin, many thanks for this at this point!

Visually, the FFL350RD is kept very simple. The orange-yellow illuminated surface is embedded in a white silicone layer. The substrate is light gray. Slight soiling of the LED (taken directly from the cut tape) is visible.

The luminous surface is interesting. At a few mA operating current, the phosphor appears yellowish, but only in a square pattern. Outside of this - the corners protruding beyond the round luminous surface - the phosphor appears much bluer. In addition, light appears to shine through the white silicone layer in a square pattern around the round luminous surface. This should reduce the luminance.

It looks a little as if a square LED chip has been used to create a round luminous surface with a circular cut-out.

Particularly noteworthy is the light shining downwards through the substrate (!). This appears to be made of either plastic or very translucent ceramic and has not yet been seen with this intensity in a high-power LED (see picture). This effect is better known from LEDs in 2835 format or PLCC.

The footprint offers no surprises. The beveled edges in the thermal pad indicate the cathode. Such reductions in the heat dissipation surfaces should be viewed critically; they further reduce heat dissipation, which is already severely limited due to the small 3535 footprint. A marking on the top or a beveled corner of the anode is more advisable here.

- Maximum reached at 8.2 A, at this point 1139 lm @ 3.91 V

- Power at maximum 32.1 W

- Efficiency at maximum 35.5 lm/W

Data for 25 °C Tsp (at 85 °C the luminance values are around 13 % lower).

Due to a lack of official performance information and data sheets, no official maximum values were specified. However, some observations can be made.

Compared to the FFL505A, the FFL350RD has a slightly higher efficiency. The Vf is very high. It is noticeable that both the luminous flux curve and the voltage characteristic deviate from the FFL505A. The plateau that forms before the maximum possible luminous flux is reached is also interesting. Either the phosphor mixture used becomes saturated above a certain luminance or the Tj (thermal junction) is lower than 150 °C, an effect that was particularly noticeable with the previously tested Moonleds MN-S3535 with 98 CRI. As the maximum current achieved corresponds to that of an LED in 3535 format (especially considering the high Vf), it can be assumed that the phosphor is saturated, another feature that clearly distinguishes it from most LEDs on the market.

It can therefore be concluded that the FFL350RD comes from a different manufacturer than the FFL505A.

However, the biggest problem became apparent after the luminous flux test. After around 3 minutes at the maximum possible current of 8.2 A, the efficiency was reduced by around 8 % at lower currents. This again indicates massive ageing of the semiconductor at (too) high currents, whereby degradation/alteration of the phosphor cannot be ruled out. In this respect, operation at over 5-6 A is not recommended. As Fireflylite does not provide any information on the maximum operating currents permitted (it only mentions “10 W”, which implies around 3 A), particular attention should be paid to the operating current when using in lamps in order to avoid premature ageing.

The luminance is lower than that of the FFL505A 3500 K, despite the higher luminous flux, which is consistent with the anomalies of the luminous surface (which have an influence on the total light emitting surface).

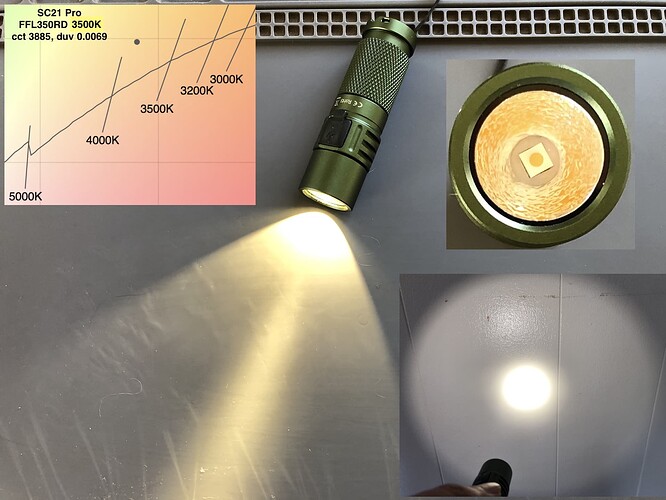

Despite the observed anomalies in the luminous surface, the beam is perfectly fine and also free of color distortions in SMO reflectors as known from some LEDs (sometimes just called “Cree rainbow”). Only rings can occur - as with most LEDs with a small luminous surface - depending on the calculation of the reflector.

The color rendering is very high. The specified 96 CRI is reached.

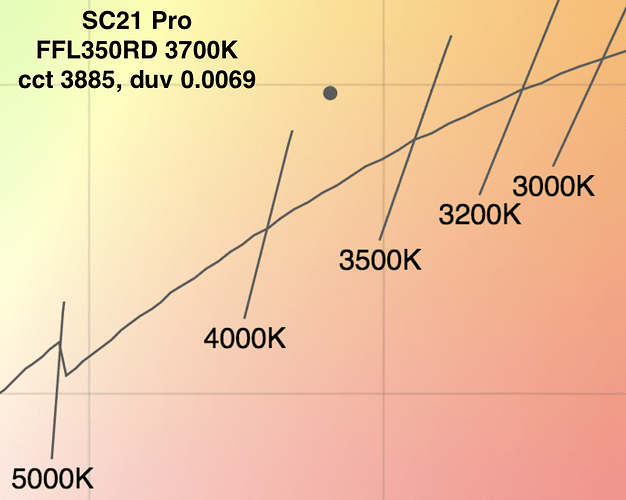

However, the light is subjectively less pleasant than other LEDs with a similar CCT. This is probably due to the duv of 0.0011 and above all to the CCT, which is significantly higher than 3500 K. The LED tested here should actually be specified with 4000 K. With this CCT in particular, a negative duv is absolutely essential, as greenish tints are particularly evident here even with a duv close to 0.

- Ra: 96

- R9: 94

- CCT: 4024 K

- duv: 0.0011

The FFL350RD remains somewhat in the shadow of its bigger brother. This is due to the high Vf, the significantly higher CCT than specified and the subjectively perceived slight green tint. There are also anomalies on the illuminated surface and a slight reduction in efficiency after operation at high currents.

The beam, on the other hand, is perfectly fine and the LED can be used in optics without any compromises. It should be clear that these LEDs do not necessarily have 3500 K and the duv can also deviate slightly. In addition, these LEDs should only be used with drivers with maximum current limitation.

Thank you for reading this test. ![]()