I'm notoriously interested in the luminance of LEDs, because this value directly affects throw.

The MT-G2 is known to be difficult about dedoming, probably due to the bumpy surface and some adhesion of the posphor to the dome. Usually I'm more than happy with the dedoming results with 50/50 acetone/thinner, with Cree XPs and XMs. But I didn't want to repeat the efforts of others to see some phosphor go away.

Instead, I tried the cut-off method. I guess a basic requirement is to cut off the dome as close to the die as possible.

As I understand it from DrJones' post and some of my experiments, I guess that in this case the die luminance is increased by photons being reflected from the silicone/air boundary.

I found an appropriate washer as guidance for the scalpel. The dome is at the left. Although I tried to cut it off in one single smooth move, the surface was both slightly stepped and opaque. As attempt I tried to polish the cut-off half. It would work with the outer shell, but the inner part is too soft. So I just put some clear silicone grease on the surface to even it up. This worked very well. The photo doesn't show it properly, but to the eye it's the same effect like water on a sanded glass surface.

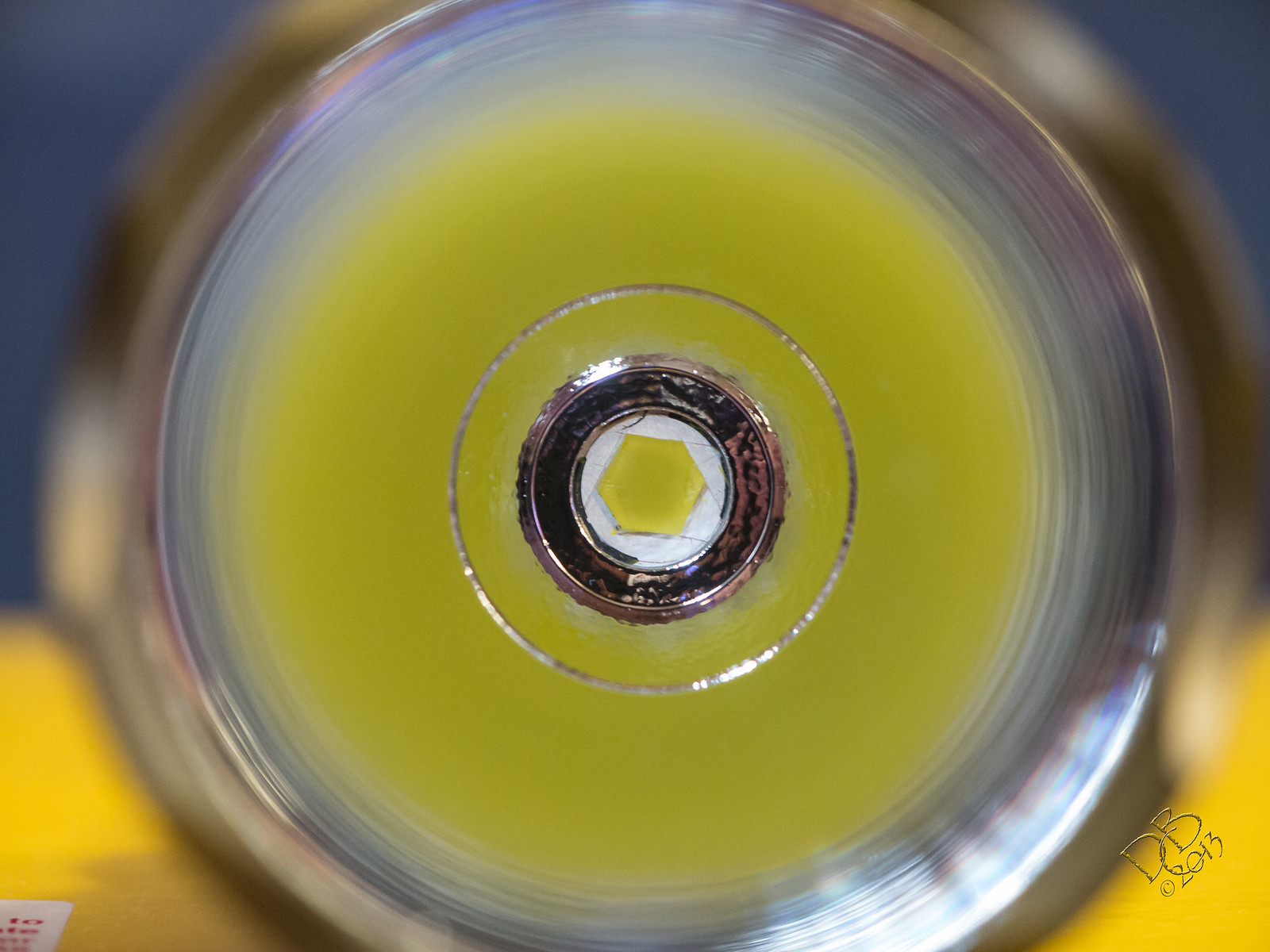

I have no device to measure high luminance (such devices are more than expensive) so I calculate it from the luminous intensity (candela, e.g. lux@1m), divided by the apparent die size. I determined the latter by counting pixels in these images:

I measured lumens with a small integrating sphere (PCE-LED1) and lux at one meter with an ExtechLT300.

He're the results:

The luminous intensity decreases to about 85%, that's a well known result for the XP and XM LEDs, too.

The luminance (lux@1m divided by apparent die size) increases by a factor of 2.2. Well, that's a lot!

With XPs and XMs (dedoming with solvent) it's a factor of about 1.9-1.95 at best.

I might as well have some errors in my procedure, however another guy in the german-lang TLF measured a factor of 1.93 after dedoming with the gasoline method, and he lost some phosphor. So I'm not too far off.

Here are the numbers:

MT-G2, P0, Cu-star, added: 5000K |

current [mA] | lum. intensity [cd] | lum. flux [lm] | luminance [cd/mm²] |

| with dome 43mm² | ||||

| 1.1 | 258 | 791 | 6.0 | |

| 5 | 21.1 | |||

| without dome 15.7mm² | ||||

| 1.1 | 203.5 | 658 | 13.0 | |

| 3 | - | 1548 | 30.8 (calc.) | |

| 5 | 725 | 2310 | 46.2 | |

| 9 | - | 3180 | 64 (calc.) | |

| 10 | - | 3270 | 65 (calcl.) |

What's the fuzz about this luminance? Max-Lux in the spot are determined by only

1. luminance (determined by the above, or indirectly by lumens, in connection with current and flux-bin)

2. reflector/lens diameter (or better apparent disk area showing the emitter) as seen from the location of the spot

3. losses (mirror reflectance, lens transmission)

It's quite some fun to predict throw (in terms of max-lux) from just reflector diameter and LED-current.

For completeness a graph with lumens (without dome)

I didn't want to find out about the current limit, especially as my switched-mode power supply unfortunately tends to spike when switching on [edit: rather meant increasing current, which is only possible stepwise]

Let alone that djozz and Match already have take some very fine measurements.