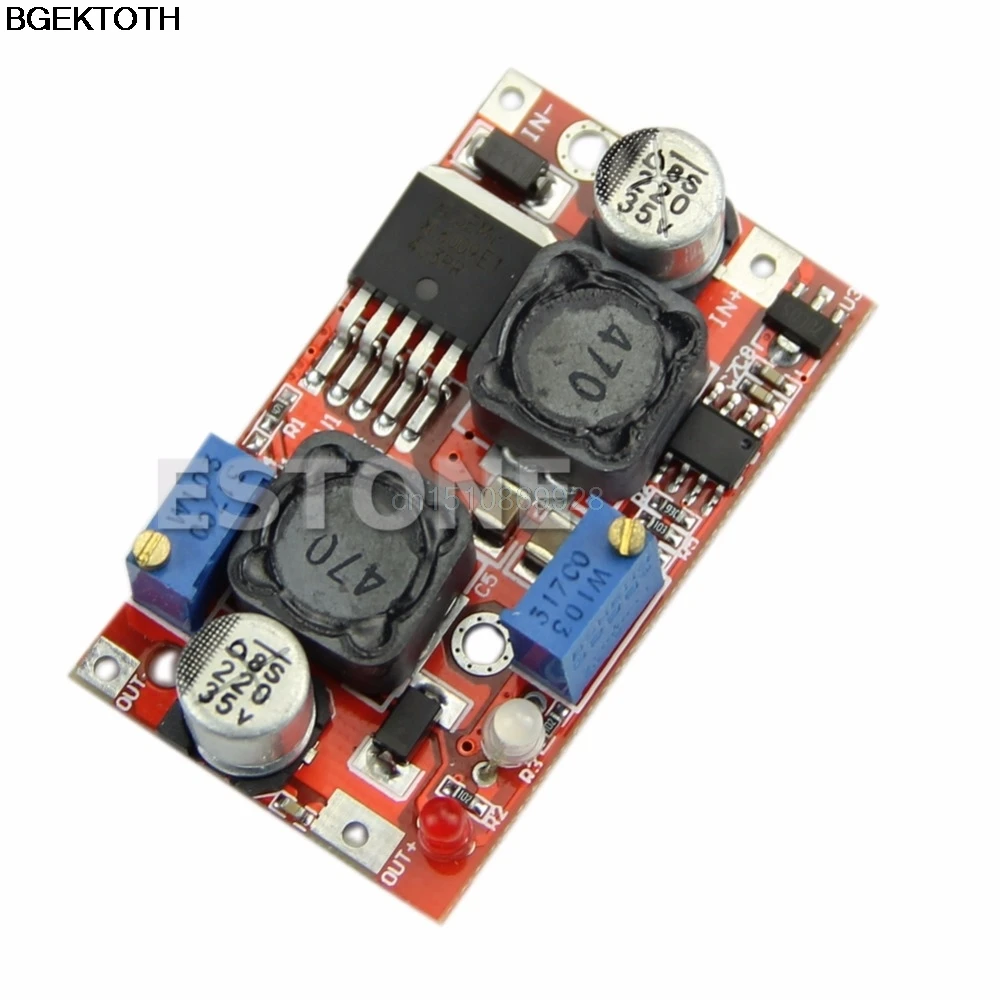

5PCS MT3608 2A DC-DC Step Up Power Apply Module Booster Power Module for Arduino @

(10pcs) MT3608 DC-DC 2V-24V Step Up Power Apply Module Booster Module 2A for Arduino @ simitter01

Quite nice boost boards. I've been looking at these lately because of inherent output voltage differences found in powerbank modules which, in practice and due to cable and contact resistances, end up playing a major role in actual output performance. When you receive a powerbank module with a relatively low Vout (like less than 5.1V), you already know that can cause power negotiation issues (lesser charging speed). I've had this issue recently with an inexpensive underperforming powerbank board.

Well, key here is these modules feature their schottky diode at the output, thus they can be carefully tuned to a given voltage and have a fairly decent load balancing when set in parallel. Soo, what do you think? Experiences? Reviews?

2 to 3 (or more) of them should provide a well balanced and powerful 5.2+V output for custom powerbank and/or other power supply requirements with a BMS fitted out 1S li-ion source, seems to me. What do you think? ![]()

everywhere, though I heard it has some :???: glitches.

everywhere, though I heard it has some :???: glitches.