Sorry, had to catch up on some sleep.

The contact to ground is made via the battery tube's top edge contact to the drivers ground ring. The nice feature about this light is the battery tube's threads and o-ring fit nicely under the head, as it threads in, so I don't believe tolerances and wear will effect this ground contact negatively. There's no hard stop for it threading in, another words. Also nice it has a simple mechanical lockout, but that feature could wear out in time. The anodizing is not high quality. Dang - haven't taken close-up pics of the threads yet, they are supposed to be square, but if you don't have quality anodizing, I would think the wear will eventually break the mechanical lockout.

The bad side? Well, I mentioned before the driver's diameter is wider than normal SRK drivers, and the battery tube's top edge is thin in order to clear the new polarity protection plastic cover added. So for driver replacement, stock SRK drivers might be too narrow for ground contact - it's a risk, didn't try it myself yet so not sure.

I re-assembled proto #3 last night, stretching out the lens o-ring seemed to work out to make the assembly easier. Proto #3 that had the weaker #'s seems to have improved now. The screw holding down the reflector was definitely loose before, now it's tight, and I think the LED's look much better centered.

The thing I like a whole lot about this light is the low profile LED alignment pieces. The cheap SRK clones are awful - thick base, high sides - these are really low profile in both dimensions, which I believe translates to more LED in the reflector, more light out.

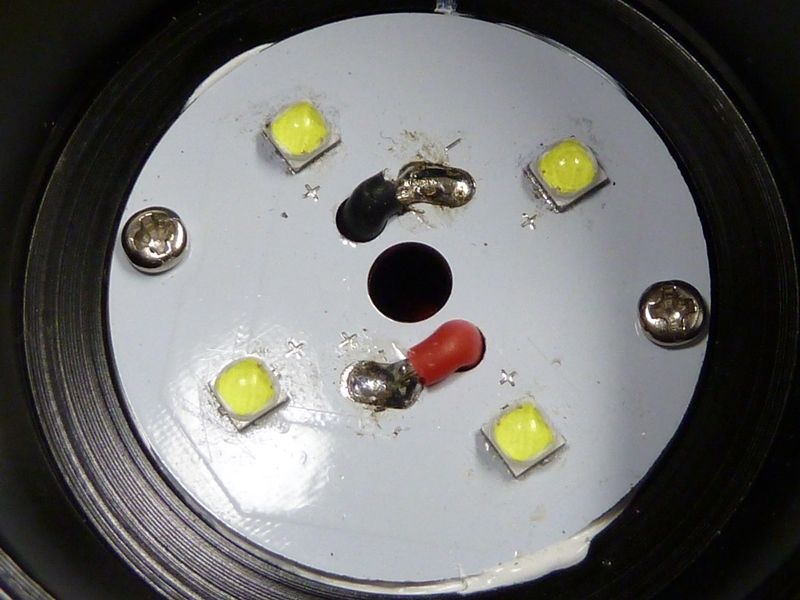

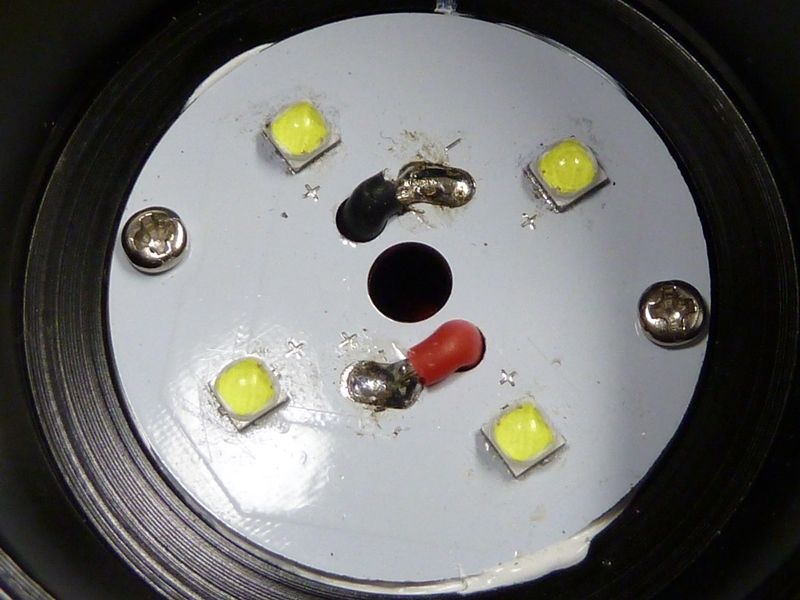

Here's what I'm talking about.

One big copper DTP MCPCB, best setup, appears identical to proto #1, accept for the screws:

This is where they made some changes - same reflector, same dimensions (18mm high, 51 mm wide, 23 mm I.D. reflectors, 7.05 mm holes), but backside machined differently. The screws were changed from flat head to pan head - an improvement because pan heads will not apply force to potentially buckle the copper MCPCB as flat heads would if hole alignments are not perfectly set. To make room for the pan heads, they drilled out holes. They also made the center hole slightly wider to properly clear the solder pads.

The low profile alignment pieces. Proto #1 used similar ones, but they are jammed into the reflector, partially broken, as if they didn't fit right. These are about a perfect fit.

Close up view of the side switch. The 4.7K resistor is way too low for these green LED's (2). The parasitic draw with these on is 0.4 mA, and with them off is 0.038 mA. The LED's are very bright, bright enough to light up your path in pitch darkness. I'd suggest about a 10K, and that should lower the drain to about 0.2 mA

I've been saying the LED's that came in the prototypes were not acceptable - CW with hints of blue and green. Thinking maybe like a 1S or 1B tint. Here's comparisons - 4X SRK clone with XM-L2 U3 3D's on the left, proto #2 on the right. First a lower output level:

Higher output level:

These wall shots are about what I'm seeing. Did a bunch of camera settings checks to get it matching pretty close. Maybe the blues and greens are a little more emphasized in the pictures, but they are there in real life.