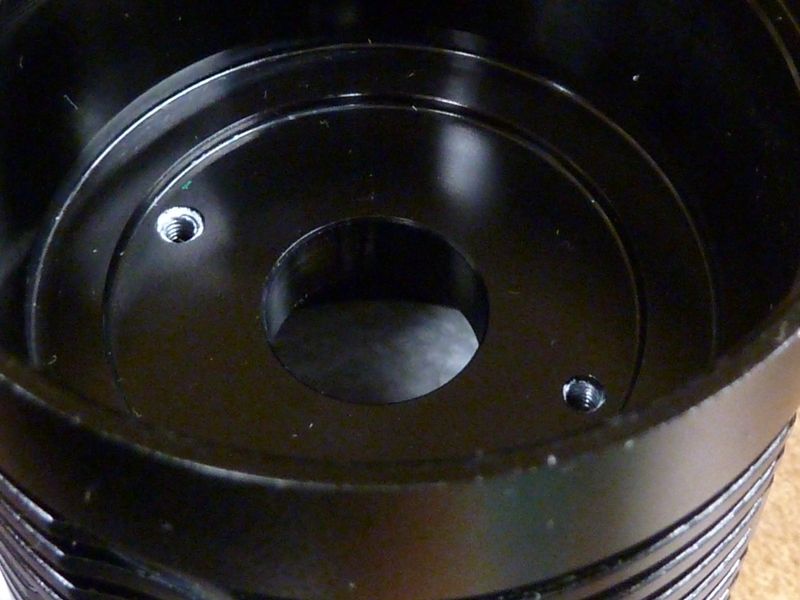

Manufacturing reality input here - a screw, even two screws, are a LOT easier to install than a very large diameter thin retaining ring. And by easier, I mean cheaper, faster, and more reliable good installation. IMO there is a very good chance that the decision to use two screws was a manufacturability decision.

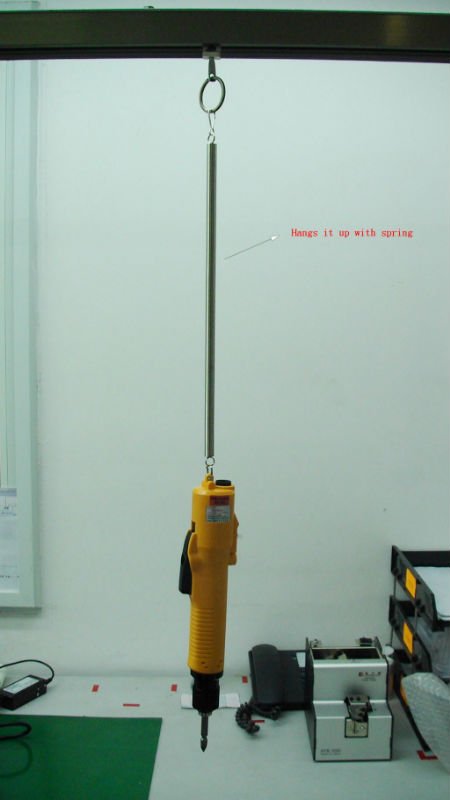

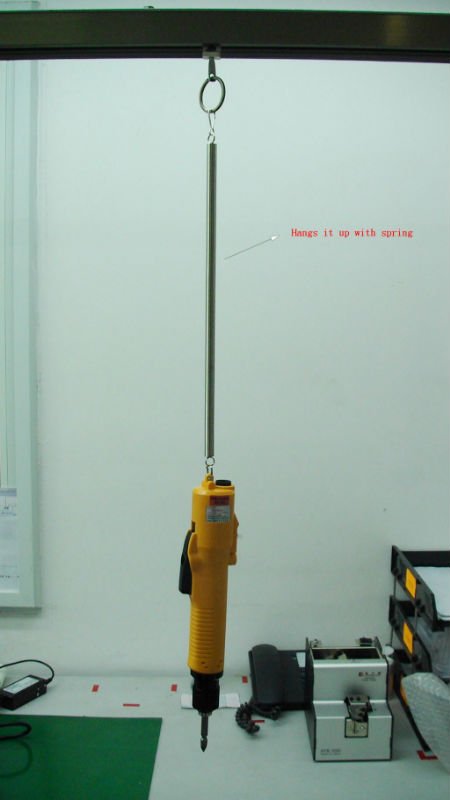

Two screws requires a (hopefully) Torque controlled electronic screw driver, and a magnetic bit, that’s it for “tooling”. Thorfire certainly already has that in house, and it will probably be about 3-4 seconds worth of process time to shoot two screws.

For a retaining ring of that size you either have to 1) slow down production to allow a worker 20+ seconds to fiddle with that retaining ring, which is an ETERNITY in manufacturing or 2) create custom tooling/fixturing/jigs to pick up the ring properly, align it properly, drive it properly, and torque it properly – and it still won’t be faster than two screws. All of that equipment costs time and money to design and build, plus it must be maintained during production otherwise it will cause more issues than it solves.

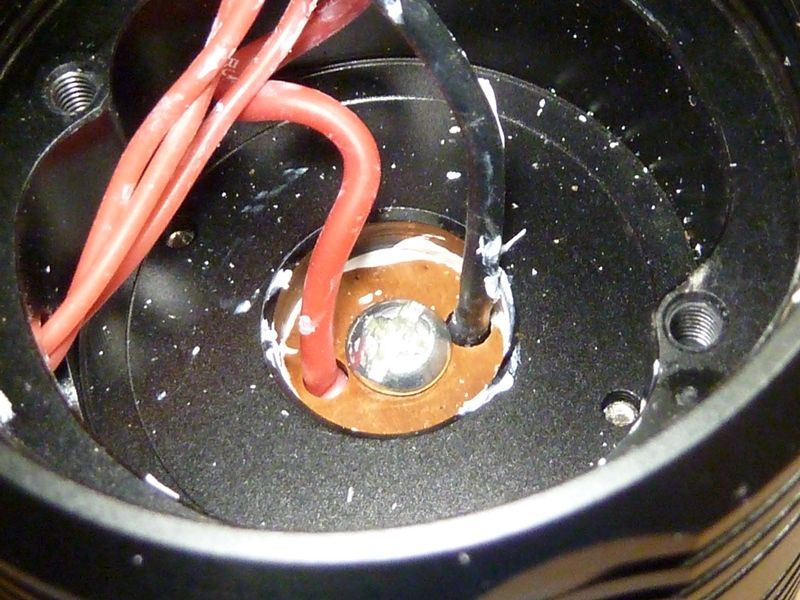

We all know how fiddly retaining ring can be to get them installed properly, and larger diameter ones are more difficult. Difficulty = time = money in manufacturing. Also, difficulty = quality problems and scrap cost when you cross thread them (and you will). Cross thread the retaining ring and you probably need to scrap the machined head and eat that cost. Cross thread a screw and you just run a tap down it and re-shoot the screw – a 60second rework process.

Other downsides to a retaining ring from the design POV: you either have to do another machining process on the head to create a second set of threads (cost, time, complexity), or use the same threads the battery tube uses, which risks the battery tube affecting the torque on the ring. We know that constantly screwing and unscrewing tailcaps can loosen switch retaining rings, the effect would be much more significant with a larger diameter ring.

And from a cost POV it is also obvious - two screws cost next to nothing, easily less than one penny. A brass retaining ring that has to be designed and manufactured specifically for this light probably winds up costing $0.20-$0.50 each (I’m a QC engineer not a buyer, cut me some slack on the wide range). That doesn’t seem like a lot to you or me individually, but it is a lot when you are making thousands of units that you are trying to profit from.

To me it’s really easy to see why they would use two screws instead of a retaining ring – unless we are willing to press the issue (and potentially pay for the retaining ring either directly with money, or by indirectly by sacrificing some other aspect), the screws are the better design for Thorfire.