Hi,

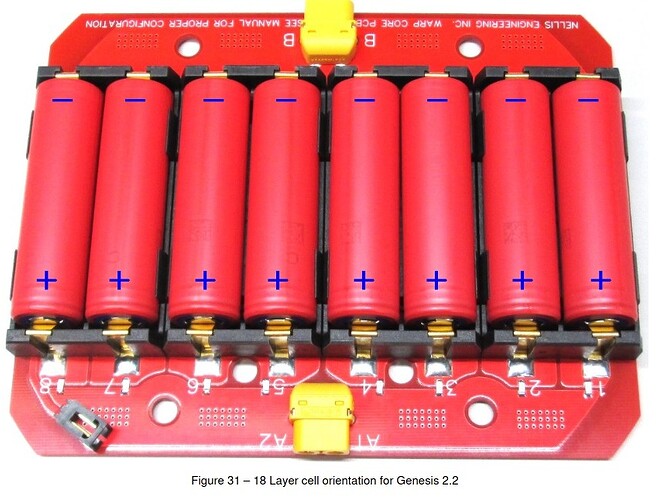

I just acquired a new scooter for use in scuba diving. It has 144 18650 batteries in it. They are all Sanyo NCR18650GC unprotected cells.

They were shipped from the manufacturer charged to 30%, and then sat, installed in the scooter, for 3 years. The battery pack has a Bluetooth BMS. The manufacturer says the BT drain is small, but in that much time has probably killed the batteries.

I’ve also been told that, if I want to try to save/use them, I can test each individual battery and, if it has some voltage, then I would be safe to charge it. Then only replace the individual cells that have no voltage.

I have an Opus BT-C3400 that I have had for several years.

The question is, what is the best approach for the batteries that do have some voltage (if there even are any)?

If a cell has any voltage (is there a minimum, where I should still junk it if the cell is lower?), should I just put it in the charger and do a normal charge? Or should I run it through a Discharge-Refresh cycle?

Initially, I figured I would just do a Refresh on all of them (that have voltage).

But, thinking about that and the history of the batteries, I’m not sure if a Refresh offers any advantage over just doing a normal Charge.

And, with 144 of them to go through and currently only having 1 Opus, doing a Refresh on them all will take weeks!

I am thinking of buying another Opus, or maybe even 2 or 3 more, to cut down the overall time this will take.

Meanwhile, any thoughts on whether a Refresh is worthwhile versus just doing a Charge?

And, for that matter, do I need to test their voltage? Or can I just put them in the Opus and let it decide whether to charge it or not? If the Opus doesn’t start charging it, then I junk it?

Thanks!