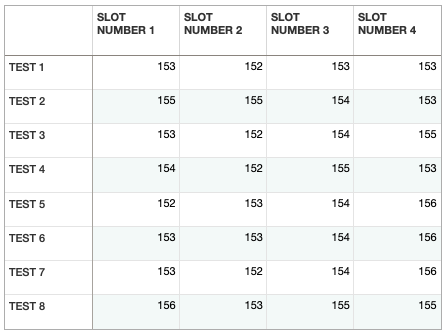

MC3000 Internal Resistance Measurement Consistency Check

After recently acquiring an MC3000, I did a very simple, small-scale test to get a sense of its IR test measurement consistency / repeatability under real-world conditions, when used as intended / directed by a typical user, while observing best practices and introducing no other variables. I’m posting the numbers in case any readers might for various reasons find them interesting or useful.

My unit is box-stock, and has not had a screw turned. It self-identifies as being FW Version 1.15 and HW Version 2.2. It was purchased directly from an extablished U.S. distributor.

For my test I used a single brand new 16340 (‘protected’) cell which had only 2 discharge cycles on it to verify its health, was then charged to 4.2V and had then sat for several weeks, which allowed it to settle and reach a stable resting voltage. I chose the 16340 as the smallest cells I use, and to minimize cell terminal contact spring pressure, which if anything would be ‘worst case’ for the test / contact resistance.

I inserted the cell into Slot 1, waited for a stable display reflecting that, pressed the ‘UP+DN’ keys to initiate an IR test, and recorded the result. I then removed the cell, and waited for the display to reflect the empty slot status.

I then re-inserted the cell into Slot 1 and repeated the above process 3 more times (for a total of 4 measurements), then repeated that entire process for each of Slots 2-4 (for a total of 16 measurements). Those numbers are listed as Tests 1-4 in the chart. When I shut the unit down and sat down to actually look at the numbers, I decided I needed more data points. I then got the unit back out and repeated the entire procedure above, thus providing me with 32 measurements distributed across all 4 slots. That second set of numbers is listed as Test Numbers 5-8 in the chart.

Looking at the numbers for a couple of minutes, I realized there was no need to grab my trusty old HP11; the numbers completely spoke for themselves and answered the question which prompted me to do the little test to my satisfaction.

I note little pattern, aside from perhaps a seeing a slight trend as I look diagonally down the chart towards the area of lower right corner, possibly seeing 1 or 2 of the ‘higher’ numbers (by 1 or 2 counts) perhaps appearing more in that area. Those are the last measurements taken on the second pass. If so, that possible slight trend would likely be accounted for by the fact that the MC3000 uses a couple of discharge pulses to do the DCIR test, and while not a big thing, the little cell did see rather a lot of them during the testing, and they do add up. I believe that as SOC decreases, DCIR increases, which could have shifted the average measurements higher by a fraction of a ‘count’ / milliohm or so. I’m talking about mouse attachments here though. In practical terms, these numbers don’t require much analysis on their surface. Note that possible factors behind the numbers is another matter entirely though.

I may have some additional comments regarding these numbers and what’s behind them later, but for now will just let them ‘speak for themselves’. Any comments or questions about what I did are welcome, and if anyone has representative data from any other unit / device which would correlate / be comparable with this data (gathered using the same real-world methodology apples-to-apples), that would also be welcomed. “What’s in your wallet?” ![]()