OK, points granted – I was thinking more like a customer than a manufacturer. As they say, when we try and walk a mile in their shoes even mentally, things look pretty different…

They do say that 21700 is one of the sizes the MC3000 is compatible with in their advertising (then as now). Maybe only flattops? Maybe as suggested elsewhere in this thread, 21700 were not as common when the MC3000 was developed as they are now.

And like Mandrake50, I am pleasantly surprised that the MC3000 is still produced. And has Firmware updates - even if we are not sure what said updates do!

Sadly the Mac side has not seen firmware updates in a few years, it is stuck at 1.15 (2020) but Windows has 1.18 (2023). When I inquired about it, they didn’t indicate if / when the Mac firmware updater would catch up to the Windows one.

Hopefully I don’t derail anything, but has anyone had charging stop with a “connection break” error even when all is clean and good?

When charging 4 new Molicel P28a simultaneously at 3 amps, I came back to it with 2 having completed, but the two rightmost cells weren’t charging and had a “connection break” error.

I did restart the charge and they finished, so the slots do still work.

Is this a quirk of the charger?

Never seen that happen in about a year with my mc3000 and certainly more than just a few hundred recharges and other operations, many with 18650 cells. I own no Molicells but I don’t think they would be any issue.

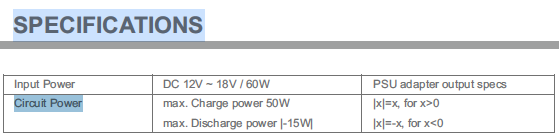

That said, 3A let 6 cell is a lot of current – I usually charge my cells at 1A even when they can take more, because I’m not usually in any hurry and going easier on the cells prolong their life. Also, 4 * 3A means 12A and that’s a lot of current, I think near the max for the mc3000? So that could certainly be a factor.

I would double-check these bays’ sliders and contacts to make sure there’s no corrosion or wear-outs, and just keep an eye on them, if it doesn’t happen again I would call it a fluke and forget about it. If it happens again with the exact same cells in these or other slots, then I’d start suspecting the cells. Yours aren’t protected by any chance, I presume? If yes, perhaps the protection circuit is being tripped either by the high current or internal temperature

Please let us know how it goes, one way or the other.

They are unprotected. Molicel P28a can easily handle a 3 amp charge. I’ll try again and see what happens. It’s new and should be able do this without issue.

They can handle 3A, but they will give you more cycles … remain healthy longer, if you use less current.

If you time the charge, you will find that the total time at 3 A is not proportionally shorter than say using 1.5A. You really just don’t gain much at the higher charge rate (unless you are under very tight time constraints), and there are definite down sides.

Using less current produces less heat in the charger and power supply too. Maybe part of the reason mine has lasted so long (12+ years).

Of course it is up to you, but worth considering.

To answer your question. I have been using Mc3000s for maybe 12 years. I have seen the connection break error , but only on flat top cells that have to be “suspended” to make contact. My MC3000 is one of the early models that didn’t have the improved contacts. So with certain cells with sort of recessed + contacts I have to get the cell positioned just right to allow them to charge. When messing with other cells in the charger sometimes some can lose contact. Witch results in the error. I just restart them and all is good.

I needed a ton of light quickly for Thanksgiving so I was crunched for time. If not, I often charge at .5 amps. It really depends.

I just need to be sure my MC3000 is not defective because I have mere days to return it.

Thanks for all the quality input!

4x3A is the (nominal) stated limit.

The max charge circuit power is rated 50W.

OP may well be operating near the ‘hairy edge’ of the limit (at some point), so it’s conceivable that some marginal factor could be causing the actual limit to be exceeded - at least momentarily.

If this happened to me, I’d clean all involved cell and terminal connections / contact points (I highly recommend DeOxit D100, but absent that use whatever contact cleaner you have), then re-test to see if the ‘connection break’ is repeatable under the same conditions. If so, I would reconfigure charge current to, say, 2.5 or so amps, and see if that eliminates the failure, then decide where to go next. At some point, I’d also consider swapping slot positions of cells originally in slots 1&2 with those which failed in slots 3&4 just to try to rule out a slot / cell-dependent issue.

With regard to my last post, there’s one additional note I’d like to add. I just happened to be looking at some photos in HKJ’s test / review of the MC3000, and while there I looked at the 4x3A charge test in his report. As most are aware, that review can be found here:

https://lygte-info.dk/review/Review%20Charger%20SkyRC%20MC3000%20UK.html

Here is the specific graph for that test of 4 slots x 3A:

His first comment following that graph is:

“Here I fast charged some cells using the full power of the charger. Input current did go slightly above 5A with a 12V supply.”

Input current is the light green line on the graph, and you will indeed notice that it goes above the max line on the graph (5A) for a time during the CC charge phase. His comment draws attention to that fact.

I’m not suggesting that charging 4 cells at 3A each is bad procedure, or that it’s likely the ‘cause’ of the “Connection Break” error that @Frostcream experienced. I’m just adding this note to underline the point I made previously regarding possibly approaching the “hairy edge” of the limit. This graph may well be showing us that “hairy edge”

The included power supply (at least the one that came with my 12+ year old MC300) is 15 volt 4 amps. So in theory it can do the 60 watts that HKJ saw. I use a supply from an old IBM laptop which is 16 volts at 5 amps. Why? Just because I am an old engineer who believes in overkill! Plus I had access to a whole bunch of them for free at one point.

I think I tried 3AX4 a few times and had no issues. Though I still don’t recommend it (nor do I use that charge rate normally). Unless as the OP had, with special circumstances.

Who knows? But I would test fully before the return period is over. Just in case it was not just a fluke.

Thanks for all the input.

I haven’t duplicated a connection-break, but now it simply won’t charge all 4 cells at 3a simultaneously. It instead finds one of the cells to be almost full and reduces current accordingly.

It doesn’t matter which cell, and it’s done it in more than one slot. I just picks a cell and decides it’s almost full.

Do you see the problem if you reduce the charge current? Maybe to 2.5 amps?

Not making excuses for the MC3000, just wondering if it actually is an input current limitation. If so maybe it is the power supply.

What are the ratings for output (volts/amps) on the one that you have?

Of course that reduces the current for the cell and the overall load. If you kill the 4 cell charge and check that single cell, what does it show as voltage and mA (charge rate)?

Just trying to help you figure out what is going on.

I gather that the cells you’re currently trying to charge are 4 brand new cells. Two questions just for the heck of it are:

-

What are the internal resistance measurements being reported by the MC3000 for these 4 new cells you’re currently using and experiencing strange results with?

-

Do you experience similar strange results when charging other known-good 18650 cells (using the same ‘program’ / parameters) that you’ve previously been using up to this point?

The ir of all cells are reported to be similar (8-10). Voltage however, does not match on the charger, though a multimeter reported them to be the same.

I haven’t tested other cells yet, I haven’t drained any other Molicels low enough yet. That is my next thing to check though.

It behaves the same when set to 2 amps as well.

The power supply came with it, it is new. I am away and can’t actually check the numbers currently.

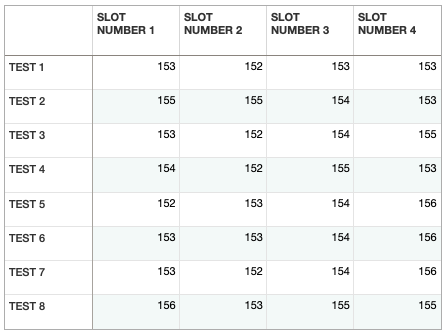

MC3000 Internal Resistance Measurement Consistency Check

After recently acquiring an MC3000, I did a very simple, small-scale test to get a sense of its IR test measurement consistency / repeatability under real-world conditions, when used as intended / directed by a typical user, while observing best practices and introducing no other variables. I’m posting the numbers in case any readers might for various reasons find them interesting or useful.

My unit is box-stock, and has not had a screw turned. It self-identifies as being FW Version 1.15 and HW Version 2.2. It was purchased directly from an extablished U.S. distributor.

For my test I used a single brand new 16340 (‘protected’) cell which had only 2 discharge cycles on it to verify its health, was then charged to 4.2V and had then sat for several weeks, which allowed it to settle and reach a stable resting voltage. I chose the 16340 as the smallest cells I use, and to minimize cell terminal contact spring pressure, which if anything would be ‘worst case’ for the test / contact resistance.

I inserted the cell into Slot 1, waited for a stable display reflecting that, pressed the ‘UP+DN’ keys to initiate an IR test, and recorded the result. I then removed the cell, and waited for the display to reflect the empty slot status.

I then re-inserted the cell into Slot 1 and repeated the above process 3 more times (for a total of 4 measurements), then repeated that entire process for each of Slots 2-4 (for a total of 16 measurements). Those numbers are listed as Tests 1-4 in the chart. When I shut the unit down and sat down to actually look at the numbers, I decided I needed more data points. I then got the unit back out and repeated the entire procedure above, thus providing me with 32 measurements distributed across all 4 slots. That second set of numbers is listed as Test Numbers 5-8 in the chart.

Looking at the numbers for a couple of minutes, I realized there was no need to grab my trusty old HP11; the numbers completely spoke for themselves and answered the question which prompted me to do the little test to my satisfaction.

I note little pattern, aside from perhaps a seeing a slight trend as I look diagonally down the chart towards the area of lower right corner, possibly seeing 1 or 2 of the ‘higher’ numbers (by 1 or 2 counts) perhaps appearing more in that area. Those are the last measurements taken on the second pass. If so, that possible slight trend would likely be accounted for by the fact that the MC3000 uses a couple of discharge pulses to do the DCIR test, and while not a big thing, the little cell did see rather a lot of them during the testing, and they do add up. I believe that as SOC decreases, DCIR increases, which could have shifted the average measurements higher by a fraction of a ‘count’ / milliohm or so. I’m talking about mouse attachments here though. In practical terms, these numbers don’t require much analysis on their surface. Note that possible factors behind the numbers is another matter entirely though.

I may have some additional comments regarding these numbers and what’s behind them later, but for now will just let them ‘speak for themselves’. Any comments or questions about what I did are welcome, and if anyone has representative data from any other unit / device which would correlate / be comparable with this data (gathered using the same real-world methodology apples-to-apples), that would also be welcomed. “What’s in your wallet?” ![]()

Thanks for this information. I don’t have a MC3000 charger. My many years of battery use starting with RC cars in 1990 gives a slight perspective of performance.

These numbers are very consistent and repeatable. I don’t think one could ask for better performance with a charger in this price range.

It would be interesting if the numbers are similar with larger capacity cells.

Quick heads up- My charger only has issues with button-tops. It charges all flat-tops simultaneously at 3-amps, no issue.

So button-tops appear to introduce significant resistance. I charge button-tops at 1 amp or so now.

I am interested in these result, as we have discussed in another thread.

I will, at some point, try a similar test with my over 12 year old MC3000.

I specifically am curious about comparing readings from cells that I use the most. Meaning 18650 and 21700 cells. Without protection.

I want to see repeatable results with spring tension involved. I also have some doubts about how the protection circuit will impact readings I want to remove that variable for one thing. But, also because I very seldom use protected cells. Again, I am more interested in testing that reflects my typical usage. In addition, I want to use cells with lower IR, that better represents the range that I usually see (maybe 20 mOhm to 80 mOhm or so). I start being skeptical about non-protected cells health that are in the 150 mOhm range. I am curious to see how repeatable the results are with lower values where a single digit of change is a higher percentage of the measured value.

In any case, I definitely appreciate your efforts. The fact that you did this may give me motivation to do my own, more comprehensive, testing.

Thank You!

PS, the repeatability range that you got is great. Well within what my requirements are.

.png)