So does the nesting bird in that tree you’re setting on fire.

Dropped some of the new XP-L HI 4000/5000K into a boost driver D4K. Rough estimate is around 2500 lumens.

I love my M8 but it is stock.

I worked on a Convoy L21A with an W2 emitter, the linear driver from Simon was making just under 6A. Took some swapping around but finally found a combination of sense resistors (R025,R010) that allowed five spaced modes and a Turbo of 8.71A at 1320 lumens from a 48G cell.

What optic are you using there?

My M8 was recently rediscovered, funny how I never really liked the C8 but the mini is so appealing! Lol

Gaggionne LLC22N, there are diamond shaped artefacts in the spill though so I’m not sure if I’ll keep it, maybe I’ll try a Ledil Tina.

Tool AA 2.0: XP-L HD CW → 519A 3500K (dedomed)

SC31 Pro: SST-40 5000K → XPL-HI ~3500K (I think)

FC11: LH351D 2700K → 519A 3500K (with pebbled TIR)

WK02: SST-20 6000K → 219B 4500K (SW45K)

SC21 Pro: LH351D 5000K → 519A 5700K

M150v2: LH351D 5000K → 519A 4500K

Ti3v2: XP-G2 CW → 519A 3500K

Some simple (single emitter) swaps I have done recently. Many thanks to jon_slider, Cheule, and others for the informative posts and videos that LED (heh) me into this modding rabbit hole! ![]()

I have a Thorfire C5 and C8S that I’ve yet to mod. Side-by-side the C5 just looks like a longer C8 with pineapple knurling.

What’s your favorite C8 mod? I have an idea for one but not the other.

Beauty !

![]()

![]()

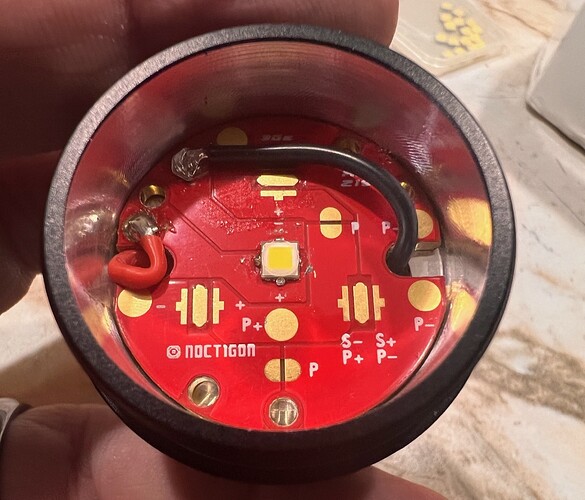

I received my first order of mezzol X6 hosts. Wanted to use an LED4Power LD4 but at 17mm it needed help to fit the new 22mm driver bay, so I helped a copper washer find a new home.

Then I assisted the X6 host’s emitter bay to welcome in the large copper MCPCB from Noctigon.

Put an old sliced LH351D on the center pad for a trial intended for longer operating time.

The pads for the leads to power up the center location are side by side instead of opposed but the X6 reflector is narrow at the base so it’s of little relevance.

Worked out pretty well, set up the LD4 at 4A, Constant Current. Starts at 1004 lumens and drops to 955 lumens in 10 minutes. Get’s pretty hot by then though, at least in the light box.

Barely puts light on the little white barn 610 yards distant.

Thinking I’ll pull the LH351D in favor of an KW CSLPM1.

I just swapped a XM-L2 for a NUBM08 on my clearance S2, using a Nanjg 105c driver (8x7135). Vf is high, but it runs at 3A on a fresh battery.

Diode soldered to the pill for maximum heat transfer.

I’m currently working on the fast axis correction to create a nicer beam with a defined dot, instead of a line. The reflector right now is only serving as a spacer, and will be removed to give space for the correction lenses. The driver isn’t ideal either, so next step is to modify it so i can run 2x18350 for a more stable output.

Sweet! Love the color choice!

Hoop, that is absolutely incredible!

I’d love a 30 second video showing a little milling.

wow.

Sofirn HS10 led swap to 519a 4500K:

dedomed the 4500K 519a:

Sofirn HS10 led swap to 519a 3000K:

Photo album with modding steps, tools, and supplies:

Dale, for your driver spacer, how do you go about doing that? Did you start with an actual washer? And if so how do you hold that for turning/milling? I assumed it was from bar stock on the lathe.

I try to avoid cut-off machining of copper. (All cut off operations actually) The Grizzly lathe is not as much a precision a device as one would think. There is enough slack in the basic components that, all too easily, cause it to jam up. Cross slide in particular wants to move and the cutting bit climbs on top and gouges. It’s a constant stress maintaining correct lines of approach. I’ve even bought a new cross slide, better but still not stable.

Yes, I started with a heavy copper washer out of a kit of various sizes. I have SO much modding stuff! This was in the modding stuff I bought from Old Lumens when he was ill. The inside dimension of this piece was close enough to allow me to machine the step for the driver. I hand cut the outer dimension on my 36 grit ceramic belt used for knife making then hand sanded for proper fit.

I am not a machinist, no training besides time served. And I forget many of the learned tricks. So, I wing it.

In this case I squared the tool head to the jaws on the chuck, semi placed my washer, ran the tool head up and pressed against the washer to true it, since the washer was not flush but inside the jaws, a small cut off was used between the tool head and washer, then I snugged the jaws. the 5” three jaw chuck is sometimes awkward with small parts. I used a new boring bar to cut the inside step.

Squared up the X6 head in a similar fashion in order to cut the relief for the big Noctigon.

Got the bill today for my little oopsie with the copper heat sink a few weeks ago. $304 out of pocket. They charged insurance a little over $16,000! For seven stitches between two fingers. Called it a “surgical procedure”.

Making me scared to DO anything!