It’s possible to have a decent beam with the original reflector (see pic) but I bought mine a few years ago. Seems that @INeedMoreLumens was having the same issue with some of his reflectors and he mentioned using an S2+ reflector, too.

Thanks!

Finally managed to get my mod working…so have a functional sc31 pro again with sft40 3000k emitter. Ugly rings and its a mess of a job, but was my first proper mod rather than repair and i picked up some good tips here along the way too.

That’s really cool! Mind sharing the details? how long was in the oven, temperature?

I removed all the internals and Orings.

Then I cleaned the grease off with Isopropyl Alcohol.

Next I scrubbed the whole light with dish soap and a toothbrush to remove the remaining grease and oils.

I baked it on the middle rack @ 500°F, in a Pyrex lined with aluminum foil.

Note: I placed it in the oven then turned it on.

The tailcap was done in about 26 minutes.

The Head and Body Tube took about 45 minutes.

I probably should have left the Body Tube in for another 5 or 10 minutes.

Note: Be sure to grease the threads before re-assembling the light!

In the right lighting you can see all 3 pieces are different shades of brown.

Thank you for the very detailed explanation and pictures. I’ll definitely do it…

one more question, does the clip get the same treatment or something else? I’ve heard of people using blowtorches on them.

The clip was done with my Hotplate 230°C, but it wasn’t changing color so I used a BBQ lighter to help it along.

I constantly but slowly moved the flame to avoid any hotspots.

Thanks!

After you bake the anodizing, is the surface finish as durable as the original anodizing? Or is it more fragile?

AFAIK what the baking does isn’t to the anodizing itself, but partially breaking down the dye used to make it black. It should be as durable as it was before.

The expansion coefficient of the aluminium is different from the aluminium oxide, so it cracks when heated. The effect is more pronounced on smooth aluminium parts than on bead blasted parts because the surface texture spread the tension evenly. I baked my Galaxy watch active (smooth blue anodization) and my mini Maglite 2AAA (smooth black anodization), and the anodization on them cracked, but the other bead blasted parts that i baked held up better, only showing signs of cracking when i heated them too much.

I had that happen on my FWAA.

I baked it for way too long and even set my oven to broil.

I was trying to get the Dark Gray to turn Tan but it eventually just turned clear.

You can see the cracks in the anodizing:

After:

Before:

Am I weird that I like the way it looks? LOL! It’s different

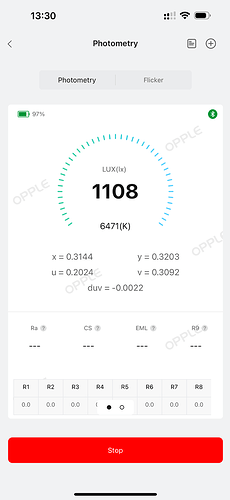

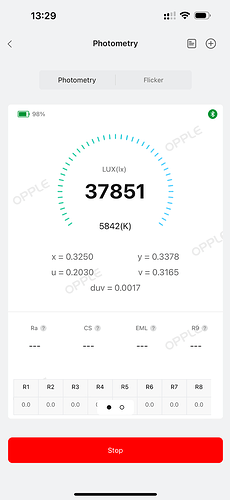

I put an SFT70 5000K in a Sofirn C8L. Very pleased. Measuring over 100,000cd and the tint/color of the light is pleasant.

Put some SFT-25R in an old BLF GT Mini. Pretty interesting LED. Powerful for its size. Hotspot the same size as a CSLNM1.F1 in a C8+. But brighter!

So much better than the old but gold XPL-HI 4000k.

Pulling about 24w on the bench power supply at 4.15v

Spill reads below BBL but hotspot above it.

Which driver did you use?

I thought that the C8L had a 3 volt XHP50.3 HI and, as far as I was aware, the SFT70 isn’t available in 3V?!?

The unmodified C8L driver - it is 6V and efficient. It holds 100kcd until thermal stepdown (I stopped measuring after 3min).

It has only ever been 6V. There has never been a 3V version afaik. Not sure where you got that info from.

Thanks for clearing that up, I must have remembered it wrong.

Good to know though, since that makes the C8L an interesting option/light whenever I have a 6V led. (I do have a SFT-70 laying around which I don’t have a plan for yet, so who knows…)

Minor mod, but with a big difference: today I made a (plastic) shim to fit in between the (rubber) button and the electronic switch of my Niwalker ETmini V1, because the button press felt very inconsistent with sometimes almost no noticable ‘click’/feedback.

Read about this mod here on BLF, but this was the first time that I tried it and I have to say: it makes a big difference! Button now feels way more consistent and with a noticable click every time.

Used a thin piece of clear plastic from some packaging/box, cut out a slightly oversized circle and sanded it down to 7mm to make it fit.

Easy/small mod, but I’m happy with the result it gave!

Photo without and with the shim: