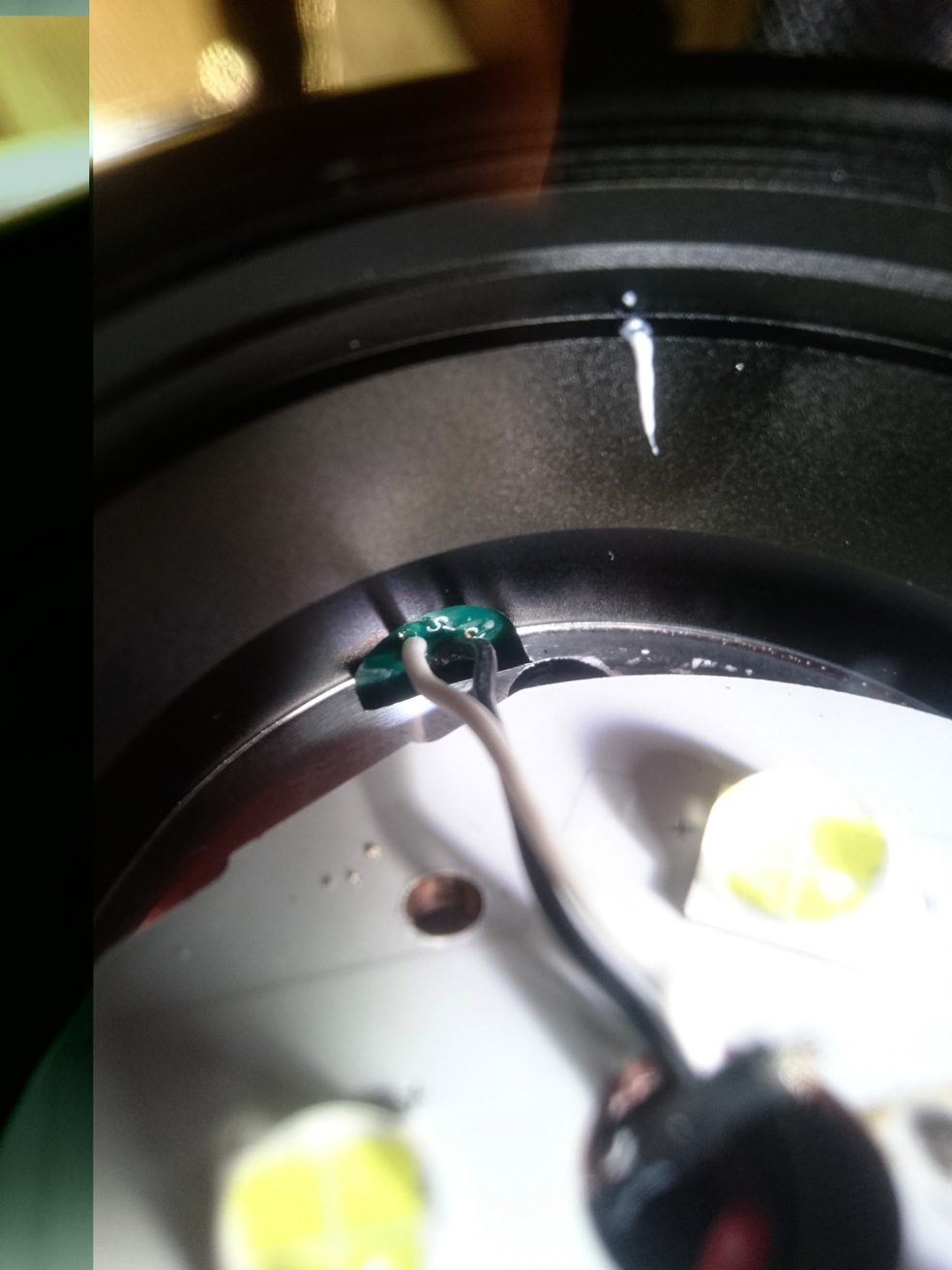

Here are the pictures, I thought different angles might show the depth better. It is a smooth “inverted dome” shape going down maybe 1mm below the surface. The bit has slid into the brass part and just keeps going that way if I use any pressure at all. As such there is basically a line down the center of that indent, to the outside is steel screw-head, to the inside is brass.

Click for full-size pic

I think I’d just cut off the head with a Dremel, remove the driver, then see if I could cut a slot in the remaining top side of the screw and see if it’d back out with a regular screwdriver when heated up some to break the bond of the glue. I’d get that driver out of the way first to avoid any more damages.

I think that’s the best approach, I just can’t seem to get the head off. What dremel attachment would work do you think?

PD, it looks like there isn’t much of the head left, if any. Can you not just pry it up and break it loose, or is that retaining ring threaded in?

There’s still a decent amount left if you compare to the other open hole. I did try prying with a small screwdriver, but the ring didn’t budge, I just managed to gouge the rim of the threads. I don’t think it is threaded in, but it might have some glue on it? Once I get the screw out I think I’ll have to punch it out from the emitter side.

Use a small round headed diamond rotary tool bit, one about the same size or slightly larger than the screw thread.

That head looks counter sunk, you may not be able to use a cutting wheel on it.

agreed, the cutting wheel would only come in after the driver is out to get rid of whatever’s left.

Like this maybe?

http://www.harborfreight.com/diamond-rotary-bit-set-4-pc-69664.html

Aweome!! I didn’t know those even existed… :person_facepalming:

Those flat ended bits are useful too but better with the round ones for your purpose.

Is diamond or tungsten carbide better?

They might be too aggressive, i haven’t used them, get both.

Diamond will be easier to keep steady, a tungsten carbide might want to grab and pull and leave you with a big gouge across the brass. Ask me how I know… ![]()

On the TM16, I have two sets of readings… both after putting in the XHP-35’s. First stock driver, second bridged sense resistor…

Stock………………….Bridged

05.556 lumens………05.4855 lumens

311.535………………484.38

707.25………………1086.75

1966.5………………2939.40

4943.85……………7072.50

So the moon is controlled separately from the sense resistor and bridging the sense resistor bumps power across the board pretty evenly. Interesting, without that separate moon mode the lowest mode would be way high. As it is, being a Tiny Monster, this is livable. Would be nice to have something in the 100 lumens area but hey, it’s a Tiny Monster Quad, right?

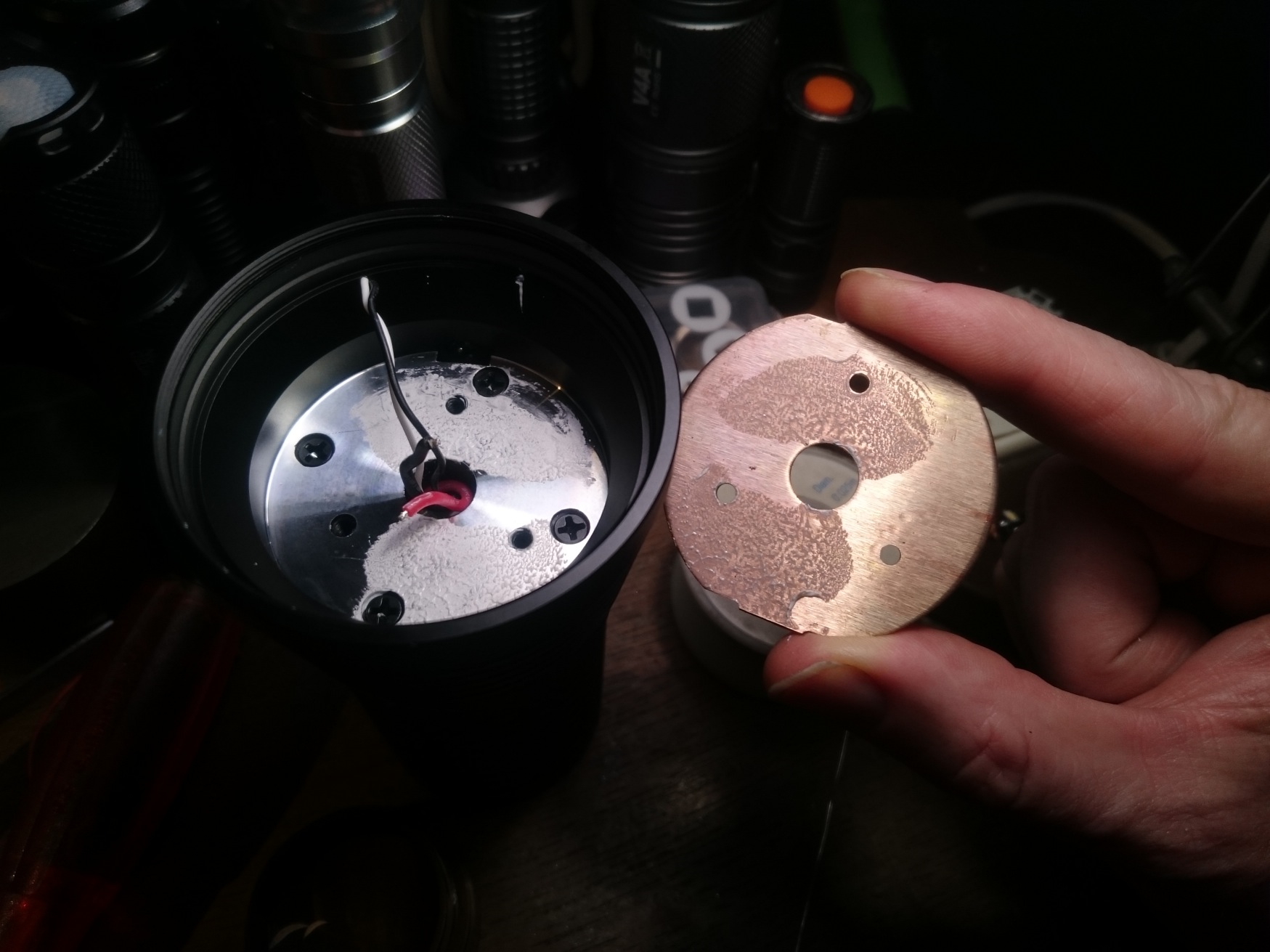

Nice! I’m thinking about 4x XHP35 HI… can you take a picture of the positioning of the MCPCB and how did you cut the 26mm maxtoch? Thanks again

How do you like the beam compared to your L6 with the P-bin emitter? Should be pretty similar specs on the top end?

Interesting concept… The L6 with XHP-70 has 4 dies close together but not touching, in one big reflector. The TM16 now has 4 of the XHP-35, each emitter is 4 dies touching so there are 16 dies in 4 reflector’s. But both are making a bit over 7000 lumens. One is pushed to the max, the other is coasting. (the L6 is pulling right at 12A, for effectively 6A per die [2S2P 6V configuration], while the TM16 has about 1.10A to each emitter [based on the Cree Product Characterization Tool and the total lumens output divided by 4], and since the 4 dies of the 35 are in series then each die is seeing 1.10A)

If I have that correct (which would be a small miracle in and of itself) then the TM16 is coasting and should last a long time. ![]()

Yeah!

TurboS stock: 9350lm@5sec 9050lm@30sec

Modded with M2 3000K from Kaidomain: 7660lm@5sec, 7360lm@30sec

So 19% loss from going to warm white.

Btw, the shelf under the ledboard is Q8 thickness, and so are the ledboard traces :sunglasses:

The rings around the leds are not center pieces but pieces of foam sticking to the board to seat the reflector in.

The leds are in series.

Here’s a boring 10 minute video of the reflow: