For all who been waiting the copper ts-10 is in from wurkkos… I love copper. I been checking every night and morning. But its here… that is all.

…and already sold out

Strangely it says 2 orders? maybe they messed up the amount…hoping

Good luck, my copacetic copper copping cohort.

Can you please tell me why copper is better than brass?

I looked at what the price was for Ali, about 70 bucks. I’d rather take brass.

Copper has excellent thermal conductivity; about twice as good as aluminum, which is the second most popular choice for heat sinks. And because copper is considerably denser than aluminum, it has a nice heft to it for those that are into that sort of thing.

Also, it looks nice. Especially with a good patina.

This should show you. Its 30 seconds long.

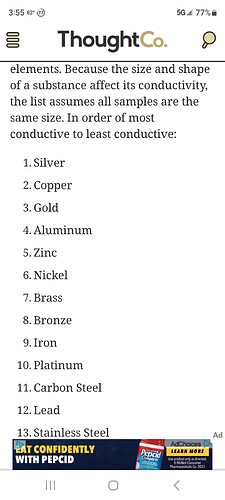

Silver has the highest thermal conductivity. ![]()

C

copper does not contain lead

brass does:

“With the highest lead content of all the brass alloys, 360 offers the best machinability. Often called free-machining and free-cutting brass, it stands up to high-speed drilling, milling, and tapping operations with minimal wear on your tools. It’s commonly used for gears, pinions, and lock components.”

copper and brass are equally heavy, but brass will trap heat (low heat conductivity), while copper will move heat (highly heat conductive). But heat is not a primary concern, when the light is in normal use at medium outputs or lower…

Both copper and brass are naturally germicidal (google for oligodynamic), and will create an unfamiliar odor on our hands. I call it the smell of dead germs… ![]()

brass stays shinier and looks more golden when tarnished. copper turns a sort of dark brown. both can be repolished easily, or will get polished by use and carry

since the brass offers 3000K and Red Aux, and the copper has neither, yet… I suggest you buy Brass now, and Copper later…

Both is Best…

Moderation in Moderation ![]()

Not all brass contains lead. There is lead free brass.

360 brass has ~3% lead as an alloying component. The result of this is basically ZERO tool wear during machining processes.

Lead does not permeate skin.

flashlight brass contains lead

the machining process causes lead to accumulate on the surface of brass

putting your flashlight, or your fingers, in your mouth, after handling your flashlight, might turn you into an idiot savant… but maybe not… are you feeling lucky? ![]()

im sure 3% lead its a minor detail in the scheme of things… otoh it is a clear difference from copper. Sufficient to cause california to recommend that parents of young children, should not let the kids suck on their brass keys…

It might be a little late for those of us who grew up with lead paint and leaded gas.

Lol, that doesn’t count. Everything is dangerous in California.

Brass is usually fine as long as you don’t eat it. That’s also why I have the “don’t suck on the flashlight” flair on Reddit.

Following the link… It says “Sorry, this item is no longer available!”

Orders 2

Brass has pretty good thermal conductivity. Similar to 7075 Aluminum.

Silver: 429 W/m K

Copper: 401 W/m K

6061 Aluminum: 167 W/m K

7075 Aluminum: 130 W/m K

360 Brass: 115 W/m K

304 Stainless Steel: 16 W/m K

Ti-6Al-4V Titanium : 6.7 W/m K

The cause of the odor is said to be a chemical reaction of skin oils with metals such as iron, copper, and brass, and this reaction creates strong smelling organic compounds, “aldehydes and ketones.”

Lead can be absorbed into your body by inhalation (breathing) and ingestion (eating). Lead is not absorbed through your skin. [source] This article is worth reading if you are concerned about lead exposure.

I have known men who have ran “screw machines” for decades, where all they ever do is handle and machine brass. They don’t have problems with lead poisoning. I have zero concerns about machining or handling brass.

Shame about the auto changing RGB aux. What on earth were they thinking ![]()

LOL! I hold my lights in my mouth quite often, dont you? ![]()

thank you… that shows copper is 3.5x better at moving heat away

not that it matters

and I appreciate your persective that the lead in brass is safe… if you believe the California Health department is run by idiots who ate too much paint… LOL

fwiw, I used to play with Lead as a child… made fishing weights… and also would carry pellets in my mouth when I was out shooting pigeons for dinner…

Maybe I would have been even smarter if not for that… I also carry brass keys… but I dont suck on them… LOL!

if somebody like brass, that is their privilege… its just a bit different than copper

This is the list that I found online. From most conductive to least conductive . All samples were the same size.

I’m guessing it’s right but I can’t confirm it.

I think thermal characteristics were not relevant in the design. Profit motive was relevant.

In certain applications it would matter. Copper having better thermal conductivity does not mean that brass has poor thermal conductivity.

Think practically. Let’s say you handle a brass flashlight for an hour a day and then you eat a sandwich without washing your hands. Then you get your blood lead levels checked afterwards. Would there be a measurable change? After one sandwhich? Ten? One hunded? A thousand? This is basically what it comes down to.

When you look up information about occupational safety and exposure limits for different chemicals and substances, such as lead, it comes down to dosages, and duration. People in certain trades develop health issues because of chronic exposure to toxic compounds. Some compounds are more toxic than others and could affect you quickly. Others could take years or decades.

“The panel recommends that maintaining blood lead levels (BLL) below 20 µg/dL over a twenty-year period, or below 10 µg/dL over a forty-year period, would be sufficient to prevent chronic effects associated with cumulative exposures.” “OSHA’s general industry and construction lead standards include a medical removal protection provision for workers whose blood lead levels reach or exceed 50 µg/dL (construction) or 60 µg/dL (general industry)” [source]

Let’s consider the blood lead levels of people who may have exposure to lead and are tested for it.

There’s a survey program called: Adult Blood Lead Epidemiology and Surveillance. (ABLES)

Some data is summarized here: Elevated Blood Lead Levels Among Employed Adults — United States, 1994–2013 | MMWR

There were 105,474 participants in the survey in 2013, and of those, 5,504 had blood lead levels ≥25 µg/dL. 20,880 had blood lead levels ≥10 µg/dL.

“Historically, in the United States, most lead exposures among adults have been occupational. In 2013, a total of 29 states submitted data on 5,491 adults with BLLs ≥25 μg/dL of which 944 (17.2%) had no known exposure history. Among the 4,547 adults with known exposure, 93.7% had occupational exposure, ranging from 42.9% to 100% among reporting states. Individual level data on 2,313 occupational cases with BLLs ≥25 μg/dL were available from 22 states. The majority of these adults were employed in four main industry sectors: manufacturing (n = 1,227 [53.1%]), construction (n = 468 [20.2%]), services (n = 194 [8.4%]), and mining (n = 182 [7.9%]). Within manufacturing, the majority of cases (n = 878; 71.6%) were among workers employed in storage battery manufacturing (North American Industry Classification System [NAICS] 33591), alumina and aluminum production and processing (NAICS 33131), and nonferrous metal (except copper and aluminum) rolling, drawing, extruding, and alloying (NAICS 33149) industries. Within construction, the majority of cases (n = 329 [70.3%]) were among workers employed in painting and wall covering contractors (NAICS 23832); highway, street, and bridge construction (NAICS 23731); and residential building construction (NAICS 23611) industries. Within the services sector, the majority of cases (n = 128 [66%]) were among workers employed in remediation services (NAICS 56291); all other amusement and recreation industries (NAICS 71399); automotive, mechanical, and electrical repair and maintenance (NAICS 81111); and fitness and recreational sports centers (NAICS 71394). Copper, nickel, lead, and zinc mining (NAICS 21223) accounted for 98.9% of the mining cases.”

Or have brass fittings on the copper water pipes going to their house… brazed onto the copper pipes with who knows what metal compound!