Do we have one of these up anywhere? I’ve been searching and can’t find it. Thanks in advance.

Match took the Vf graph out of his post because he had had a faulty meter and did not trust the values. I guess (being fed up with testing, as he claimend) he has not got into redoing the measurements (yet?).

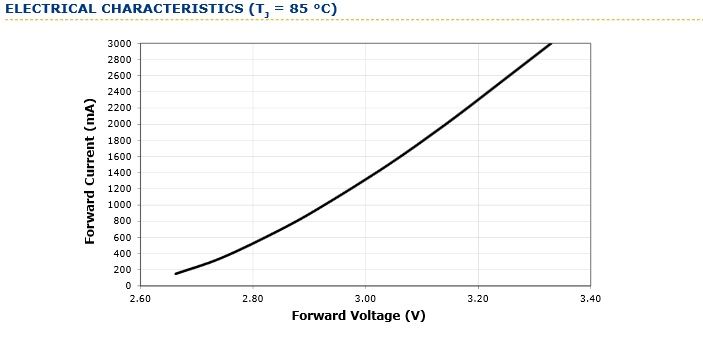

The XM-L2 datasheet has a Vf to If graph.

True, but only up to 3A.

The OP didn’t specify a current range that he wanted a graph for. In the absence of anything better, the datasheet graph seemed like the best option available to him. Is there a better graph available? I didn’t see a link in your post.

PPtk

Folks, Long time no see... Since most of you are now aware of my testing procedure, I'll be brief here. The following is a test of the Cree XML2 on a standard aluminum 20mm star, along with another xml2 mounted on a copper sinkpad. (member vestureofblood was kind enough to send me out these for testing). [image] Graphs speak louder than words, so here they are. The first one is the XML2 on a standard star, followed by a comparison graph between a standard aluminum star and a copper sink…

Here's the graph from the Cree datasheet for reference:

-Garry

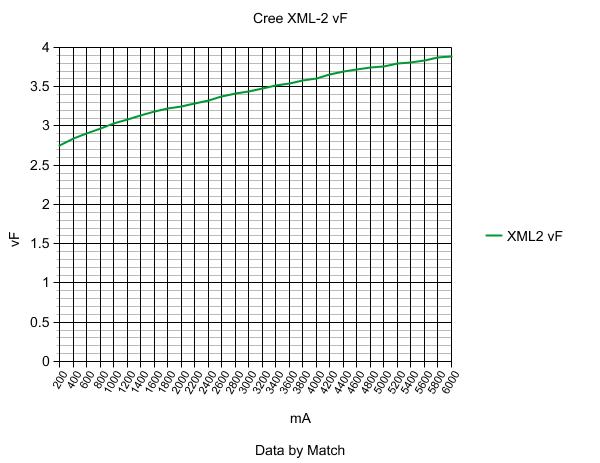

Just in case you would like to check Match's original xm-l2 vf graph here you go. But as Match stated in his OP this one is not accurate.

Thanks jamio. Given that Match's measurements were precise throughout the testing procedure, the Vf plot shows how effectively a direct to copper bond facilitates heat transfer--or rather, how a dielectric layer does not. The emitter mounted on the copper PCB hits "3.5V" at 2.2A whereas the one on the traditional PCB hits "3.5V" at 2.8A. Or, the former emitter simply has a higher Vf, though I doubt this is the case given the increasing Vf disparity at higher drive currents.

If those Vf numbers are accurate, I think it is more beneficial to run an XML2 on an AL star instead of a copper one.

If those Vf numbers are accurate, I think it is more beneficial to run an XML2 on an AL star instead of a copper one.

Me thinks you should re-think that statement…

Lets use a random Voltage (Vf) of 3.8V. Pretty reasonable drive voltage for a loaded 18650…

At 3.8V, the XML-2 On Aluminum will be drawing about 4.3A and Making about 1225 Lumens

At 3.8V, the XML-2 On Copper will be drawing about 3.4A and Making about 1250 Lumens

So, On Copper, You can generate Less Heat (12.92 Watts vs. 16.34 Watts), Extend your run-time by 26% and still make 25 extra lumens.

I think I’ll stick with Copper…

PPtk

Thanks for the input. I’ll keep that in mind as I might build a overdriven xml-2 light soon.

In terms of my current idea for a build, I’m not planning on pushing it past 3.0A since this would go in a p60 host. I’ve also been reading about the linear regulators and comparing the voltage sag of the panasonic 3400 cells. To maximize the “regulated” runtime at below 3.0amps, I think the lumen gains over Vf increase is not worth it.

we really need accurate testing numbers

didnt he pull that graph because he just thought the numbers may not be correct and wanted to verify them? could have sworn that was the case…

we really need accurate testing numbers

I have some 5000K/3C/T6 XML2’s and sinkpads on the way… I also have the Sphere ’o Many Mysteries…

didnt he pull that graph because he just thought the numbers may not be correct and wanted to verify them? could have sworn that was the case…

Yea that was the reason. I was just assuming they are reasonably close and that I can at least use the data comparatively.

Ask and you shall receive....

I finally got my meter back from cal, and was able to redo the test. The emitter was mounted on a sinkpad.

Time to go update the original post.

Your a champion Match. Thanks. I’m not electrical literate but are the voltage and mA in the opposite places?

Nice!. Watch out the mA and Voltage axis are switched.

Your a champion Match. Thanks. I’m not electrical literate but are the voltage and mA in the opposite places?

I'm sure that is your electrical illiteracy thinking that  .

.

But hey, that is a quite different graph with way different implications for practical use, eternal thanks for redoing them, Match!