I think it must have been on moon or low and sneaked past the low voltage cut of

I will put a low quality protected cell in and run it down to 3v on high and switch to moon to see how it acts

Because I am curious, and possess limited electronic knowledge… what is the bleed resistor’s purpose? Thanks.

Is that true even if the tailcap is turned (on the aluminum lights) so the tail LED isn’t lit up?

I was assuming the driver would protect me from overdischarging the cell, as long as I turned the tail light off

(I know the light gets dimmer and in ordinary conditions I’d recharge it sooner; I’m thinking of emergency use when I’d want to stretch the usefulness of the light out as long as possible)

Thanks Tom and Sharpie

Thought about it and will first check carefully

AFAIK the bleed resistor allow current to flow while the light is off (its bleeding so to speak) AMD that current powers the tail light

In lock out there is no connection so no drain of power, an advantage of the ALU over CU

Thanks for the details

Ohhhh, yes - think Sharpie has a much better, more likely explanation.

I added an XP-L 3A into the X5. LOVE the beam pattern, as it’s much more usable to me as an EDC light now. It was a bit tricky to get the focus right. An XP-G spacer was the perfect thickness to get the focus right, but due to the thick MCPCB, the head bezel left a pretty big gap instead of screwing all the way down.

I used a thinner DTP MCPCB which in conjunction with the spacer, was the perfect thickness to screw the bezel down completely.

I get 16240cd (255m).

On the X6 with XM-L2 5C, I get 26560cd (326m).

Yes Sharpie you seem right!

I did not let the cell go down too far but after the light shuts off there is drain so I now lock them out.

For those with SS/CU, would some teflon tape carefully applied on the rear threads give you lock out?

It’s easy enough to remove if it’s no good.

No, teflon tape doesn’t work well for lockout. If you put on enough of it, it can work… but it wears through pretty quickly.

Maybe if you smoothed the threads first, it could last longer… but it’s still not a good long-term solution.

No, teflon tape doesn’t work well for lockout. If you put on enough of it, it can work… but it wears through pretty quickly.

Maybe if you smoothed the threads first, it could last longer… but it’s still not a good long-term solution.

++1…… yep, tried that……… didnt work. Much easier to just take the battery out when you are not using it and use the Al as your EDC. Even if you dont the batt will last a couple of months :student:

For those with SS/CU, would some teflon tape carefully applied on the rear threads give you lock out?

It’s easy enough to remove if it’s no good.

I use on my bare A6 some clear lack. But on my Cu X5 it doesn’t work. Probably I have too much free/overlapping lack.

Hi guys,

Just got the BLF X6 yesterday and my driver retaining ring does not tighten. I can turn it with a toothpick so that is pretty loose. Anyone else has this issue or a solution to the problem?

Thank you.

Corzy, it’s a known problem.

First cut on a search: site:budgetlightforum.com X6 driver retaining ring loose - Google Search

you can narrow it down by improving the search (or someone with a better memory will come along)

There are fixes suggested (both X6 and X5)

Thanks hank, I did do a search but results if I remember correctly pointing to tail retaining rings.

I will try to do a search again in case I missed something.

The closest I got is mattlward’s X5 ring that drops off the thread at the top of the driver.

Some others pointing to the Eagleeye version also but could not find something on the current Manker/ Astrolux built version.

ok, I think it’s somewhere in here

I spoke with bugsy36 about opening this thread to keep the original g.b. thread clear of questions and answers. Somewhere the op could be edited over time to include some basic flashlight operation, overview/troubleshooting and some mods and pictures. Of course I agree the darn thing should work when it reaches your door.But this will give some beginners (myself included) a chance to learn. Let’s do our best not to trash this thread with rants.

I will ask that this op be del…

To snag the ring if it’s gone past the end of the threads — because the driver isn’t quite thick enough or the notch it sits in is cut a little too deep, same result —

— use a needlenose plier in the holes in the ring, point the lens up, gently rotate the ring counterclockwise until it engages — falls onto — the threads then back it on out slowly. Don’t twist against any resistance, you don’t want it cross-threaded. Then you can add a little bit of something to the edge of the driver to thicken it up a bit before you try to turn the retaining ring tighter again. But that’s all from memory, this has happened off and on on a variety of pills/lights. Best wait for someone with a better memory. Oh, I said that already (grin).

Thanks again hank.

What you’re describing sounds like I have to add or somehow shim the gap between the driver and retaining ring?

Will have a go at a search again in case I missed something.

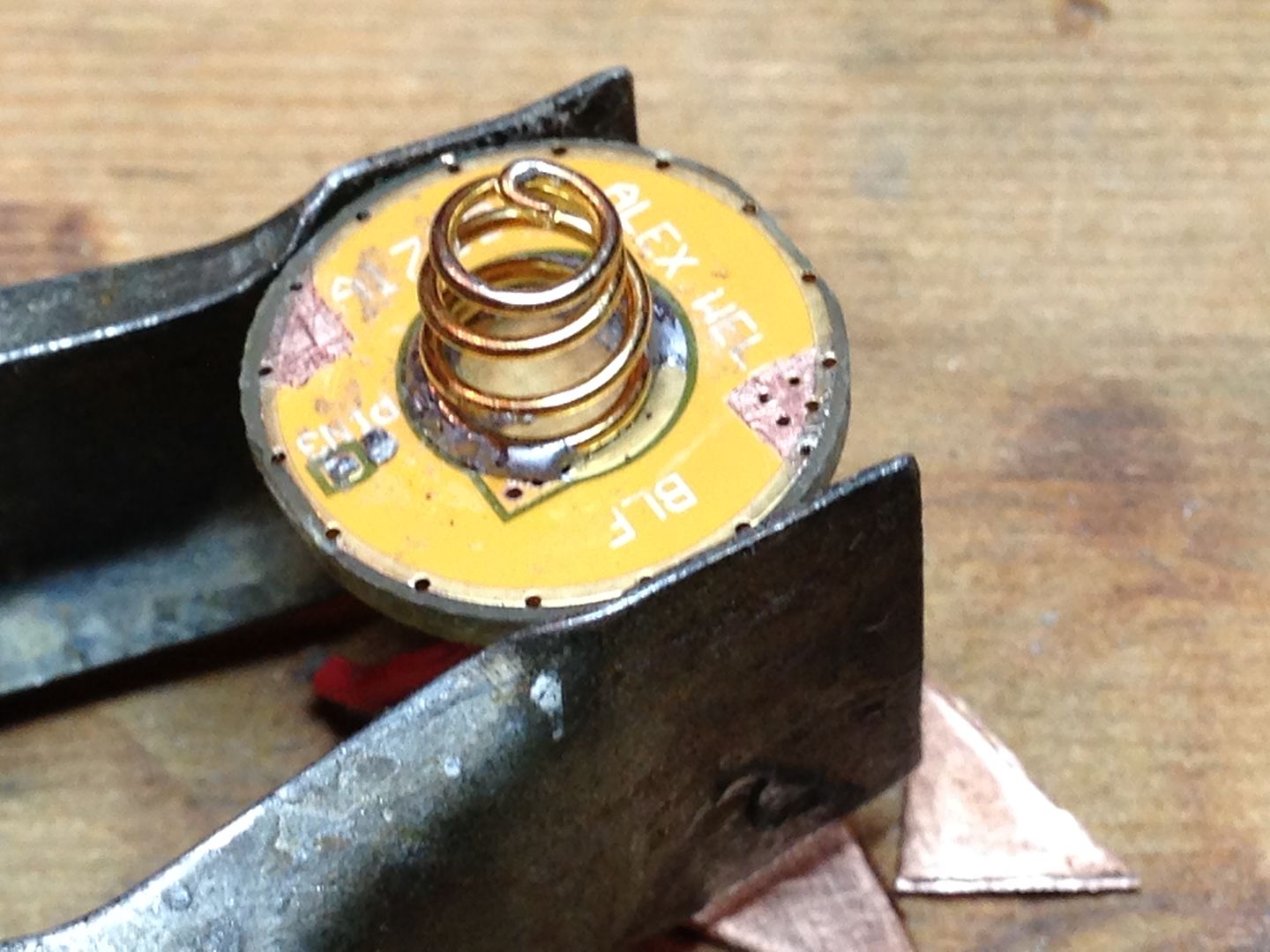

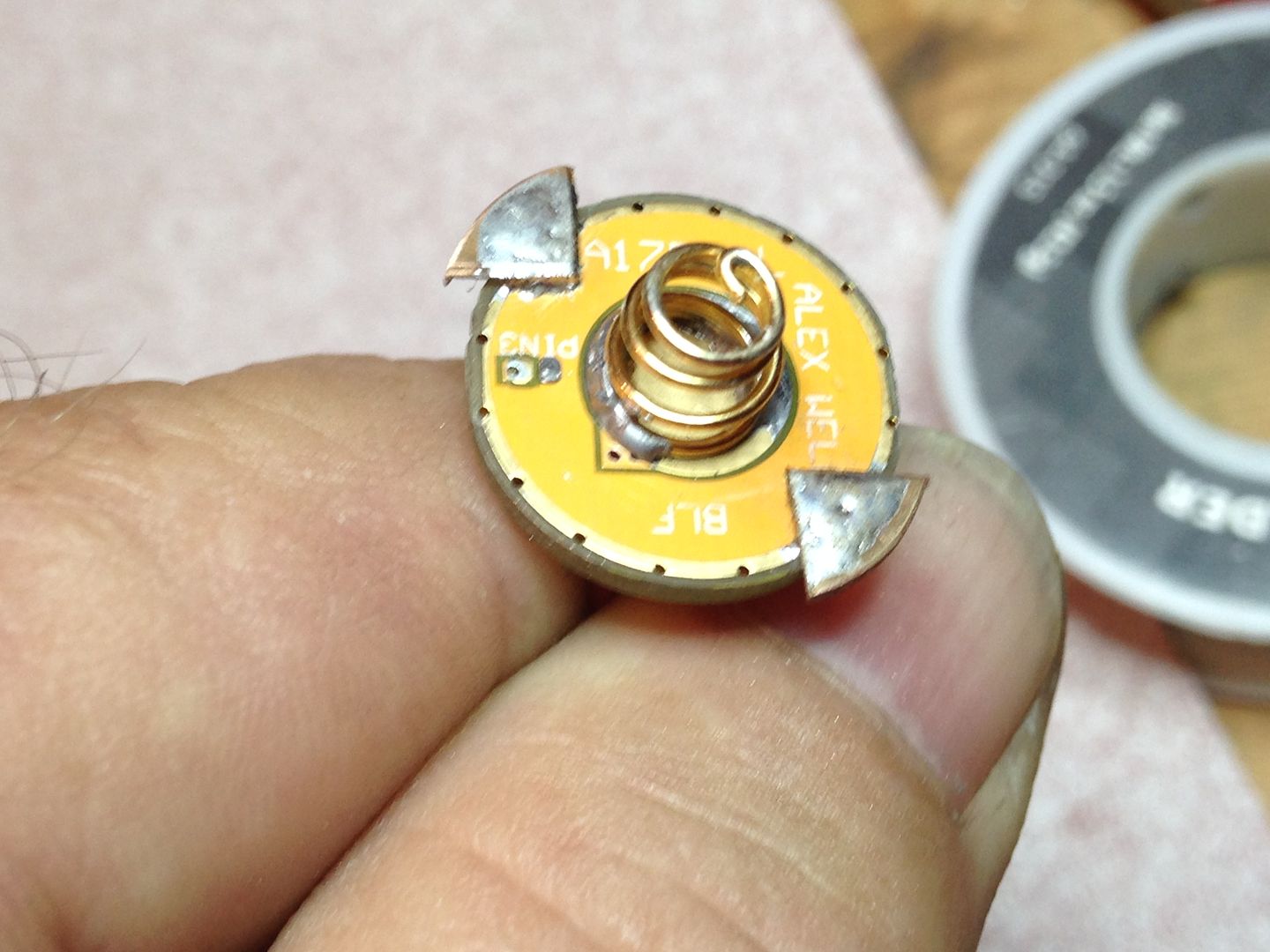

In my case the threads stopped short of the driver with no relief cut so the ring would not snug down the driver. I scraped a bit of solder mask and added two shims to fill the gap.

Thanks for your input Rufusbduck. Is that a BLF A6 that gave you the problem?