I did output tests on a XHP50, and a XHP70 (and an MT-G2 once more, for direct comparison in the same set-up), all on DTP copper boards.

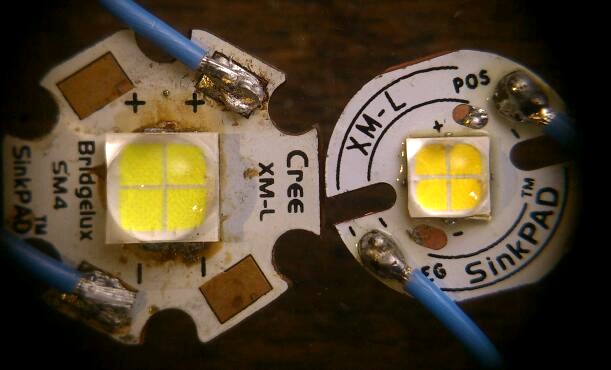

The XHP70 was a N2-bin 6500K led from Mouser, the XHP50 was an unknown bin led sample that Hank from intl-outdoor sent me to test (thanks Hank!), it looks like a neutral tint between 4000 and 5000K. The MT-G2 to compare them to was an M0 bin 4000K on a 16mm MT-Noctigon from intl-outdoor (because that is what I had in house). Here's the three together to show the sizes, note that the MT-G2 is a whole lot bigger, especially compared to the XHP50.

Let's start by saying that I do not trust the XHP70 output results below, it was a makeshift fit onto a 20mm XM-Sinkpad and I suspect that the heat path was not optimal and that that shows as a disappointing performance at high currents. I soldered three copper bits on the pads to widen the distance between the electrical pads to make the led fit. The reflowed result does not look pretty although the solder connections are good, without shorts from the electrical pads to the core.

The other two leds were reflowed well onto fitting boards, so I trust that these tests on them give their maximum possible performance. I illuminated the two XHP leds that I tested together with a 3000K XHP50 led from Mouser that I did not test with a 365nm UV-light. You can clearly see that the XHP50 led is a warmer tint than the cool white XHP70.

The test set-up is the same as during my XP-L tests, except that I used a different integrating sphere and that the ledmount cooling fan was set at its max of 12V because of the high wattage emitters at test here.

The expected outputs were larger than my integrating sphere could measure (3300 lumen), so for this test I used my work-in-progress-new integrating sphere that I have not fully characterised yet, that has a bigger range. From what I did measure it works fine, but it does not have the inner coating yet (just the bare sanded styrofoam). But because I'm comparing tints that are not miles aparts it should be ok (thread about the new sphere here). A snapshot during the measurements:

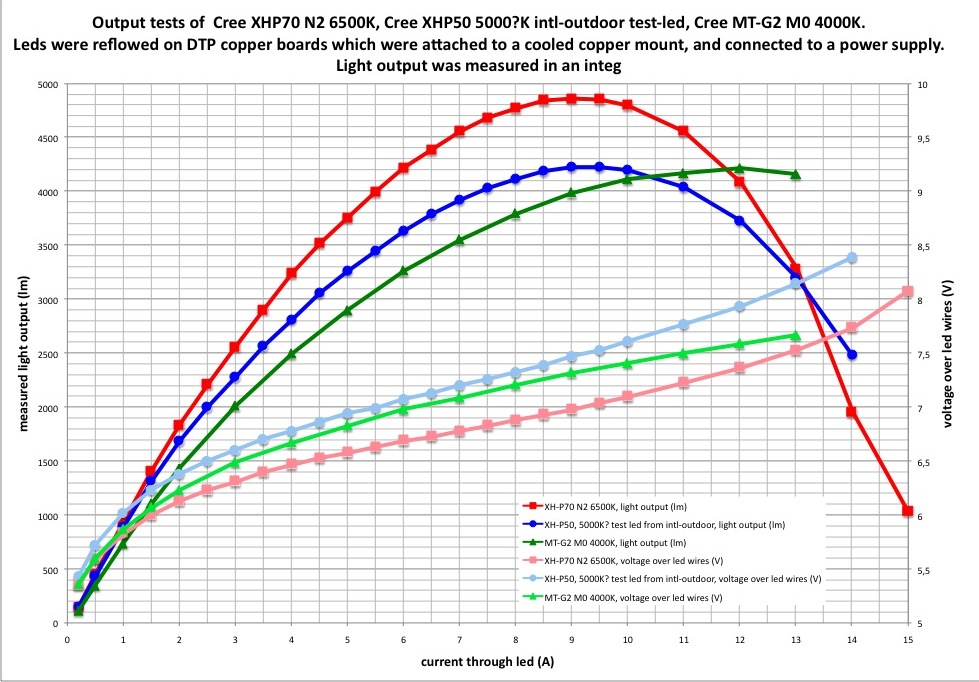

This is what I found, and it is interesting! (I see now that the chart title is missing 'egrating sphere' at the end). EDIT: by request of RaceR68 I improved some chart parameters (data are the same).

*the voltages of the three leds are comparable at all currents. In a single li-ion situation with single-die white leds, such a 0.3V voltage difference that you see here would be highly significant because the overhead voltage is so critical, but because these leds will usually be driven by two li-ions in series that give way more generous overhead voltage, a 0.3V difference matters less.

*this particular MT-G2 led in this test maxes out at 12A, that is an amp higher than in my previous MT-G2 test. It could be the individual led, but it could also be the better and active cooling that the copper ledboard-mount provides, that was not yet made at the time of the first test.

*the XHP50 is performing better than the MT-G2 up to 10 amps! (the tints of these two are not that different btw). This may not be a big difference but remember how much smaller the XHP50 is, how much cheaper, and it fits standard XM-L boards and reflectors! (ok, there's the donut hole problem that the MT-G2 does not have  )

)

*the XHP50 has a max at 9A, lower than the MT-G2. It could be the result of the very different type of die, but more likely is that the small footprint of the led is even with the best possible mounting not enough to dissipate the heat at high currents (~50W of heat at 9A!); it is heat sag what you see. If you consider the XHP50 as four 2S2P XP-G2 dies (XP-G is about the size of the dies), the maximum current per die could be 6.5A, so because the current in the XH-P50 is shared between two strings of two, a maximum output at 13A is what you could expect if heat sag was less.

*the XHP70 is behaving like it has enormous heat problems at higher currents. If it would deserve any reason to exist, the performance should be way better. The dies are XM-L size, so if heat was not a problem its maximum could be at over 16A (2x8A for the two strings). So I think my poor mounting is the cause here. Dale has measured an output of the XHP70 out the front of a flashlight build of over 6000 lumen already, so it seems that something is wrong here. If I can lay my hands on a DTP copper MK-R board (Cutter has them, *sigh*) I will redo the XHP70 test to see if it does better then.

*all three leds, after the test, were set at a lower current again (the current that gave 80% of the maximum measured light output to be precise) to see how they suffered from the high stress of the test. All three performed similar as before, these are all very tough leds!

*if I compare the led output at lower current (3A) to the numbers that Cree provides, even though a bin is a range so I can't tell anything definite, it seems like the djozz-lumen is on the high side, for the XH-P70 I measure 4.5% more than Cree, for the MT-G2 I measure 8% more than Cree. I assume here that the leds were kept at 25 degC, which in my set-up, at 3A, I think that will not be far off.

So that's my tests sofar. I'm impressed, for now by the XH-P50, and eventually probably by the XHP70 too (as Dale already showed). I tried some reflectors on top of the bare leds, and I find it indeed a pain to make a good beam without donut or other beam disturbances, even with OP-reflectors. But with an OP-reflector and some fiddling with the focus I could make very decent beams that do not look perfect on a white wall, but are really adequate in practical use of a flashlight.