I managed to short a flat top battery doing that with another charger. The insulation ring might have been a bit small…

Thats not good.

I have had that problem with AAA batteries on every charger I own. I have to raise the battery 1/4 inch before locking the clip. Otherwise, no contact.

It would be nice if an AU figure 8 cable with insulated pins is included when sold in Australia.

Yes.

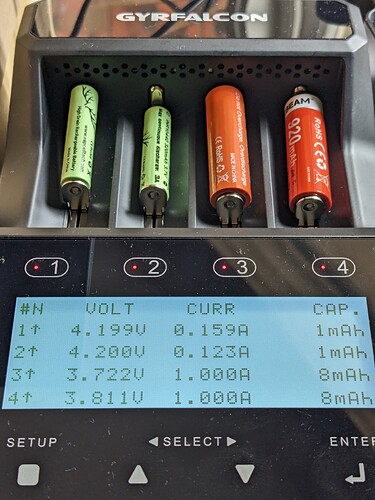

| Cell | Top | Supported? |

|---|---|---|

| Vapcell 10440 | Flat | Yes |

| Vapcell 10440 | Button | Yes |

| Shockli 14500 | Flat | Yes |

| Acebeam 14400 | Button | Yes |

There’s flat, and there’s flat and recessed, do you have cells like this ?

I have some Samsung 40T and Vapcell T50 that are recessed by 1mm. It’s not very recessed.

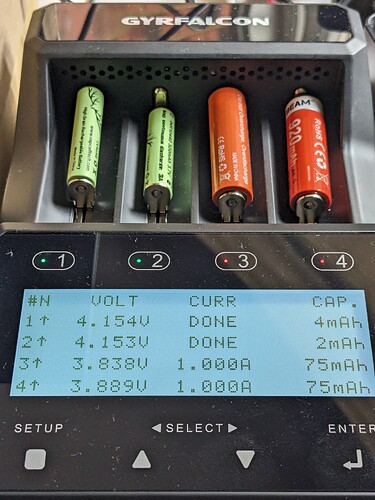

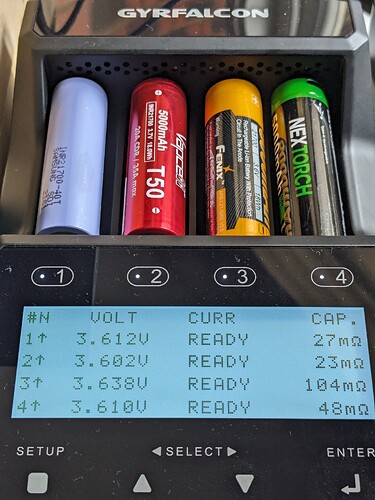

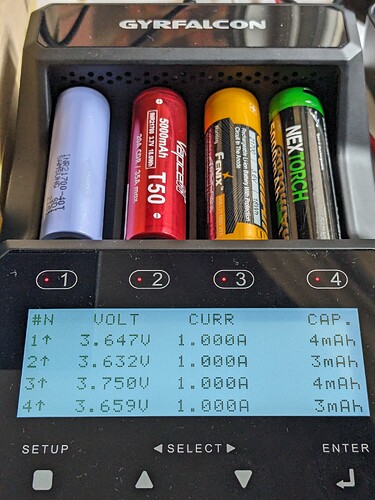

| Cell | Top | Supported? |

|---|---|---|

| Samsung 40T | Flat | Yes |

| Vapcell T50 | Flat | Yes |

| Fenix 21700 | Button | Yes |

| NEXTORCH 21700 | Button | Yes |

The NEXTORCH 21700 fits comfortably. It’s about 76.4mm long.

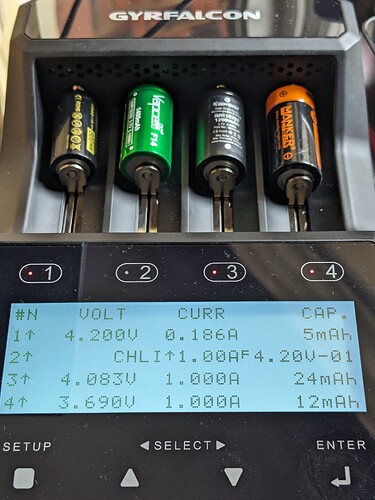

Vapcell F14 18350 is recessed and it struggles to connect.

| Cell | Top | Supported? |

|---|---|---|

| Sofirn 16340 | Button | Yes |

| Vapcell F14 18350 | Flat | No |

| Keeppower 18350 | Button | Yes |

| Manker 18350 | Button | Yes |

Would be nice ![]()

Other color than black -not white, I think it will not stay long white- My only non-black, the Skyrc NC1500 really looks nice because the color is unique compared to all my other chargers.

But first finish the charger ![]()

I dunno what is “realistic” for you?

Every -good- reviewer will wrote what he experienced with the properties, what he likes/not likes or abnormalities.

Are these ofter reviews not “realistic” if they don´t copy HKJ-style? If they emphases other points?

Even HKJ-reviews have lacks because he only use a few cells to test it. And I don´t understand why charger x have 3 ![]() and charger y have 2

and charger y have 2 ![]() in some cases. I mean this for chargers I have.

in some cases. I mean this for chargers I have.

I like reviews from different angles but at least my personal experiences/opinios will decide

It´s very hard to understand your arguments … and why you not just buy the MC3000 even though you think he’s superior to the Gyrfalcon ![]()

But first finish the charger

The first small-scale production has been completed. The estimated time for the local distributors to shelf and sell is either mid-March or by the end of March.

I told you I use a translator, I’m sorry you don’t understand.

It´s OK ![]() , I´m also no native english speaker and it´s also hard for me to undertsand what other people mean and they have a hard time to understand me

, I´m also no native english speaker and it´s also hard for me to undertsand what other people mean and they have a hard time to understand me ![]()

Worldwide or in selected countries?

I´m not sure whether I´m one of the early adaptors, for my daily use the support of AAA-cells should be good and I don´t know how good the contact is for these3 cells.

My experience some multi-chem-chargers are awful in this case (Zanflare C4, Nitecore UMSx, Keeppower L4) and some are good (Dlyfull T5/A4), many are mediocre.

Argh, now you made me curious ![]()

I would like that ![]()

A good charger which have a good design is welcome ![]() , I will find it easier in my charger-collection.

, I will find it easier in my charger-collection.

But a question, some competitors write on the packaging that flame retardant ABS is used. Are the colored charger use same/similar material?

some competitors write on the packaging that flame retardant ABS is used.

Flame-retardant ABS + PC is used by the S8000 and S4000 Pro.

Are the colored charger use same/similar material?

Yes, flame-retardant ABS + PC.

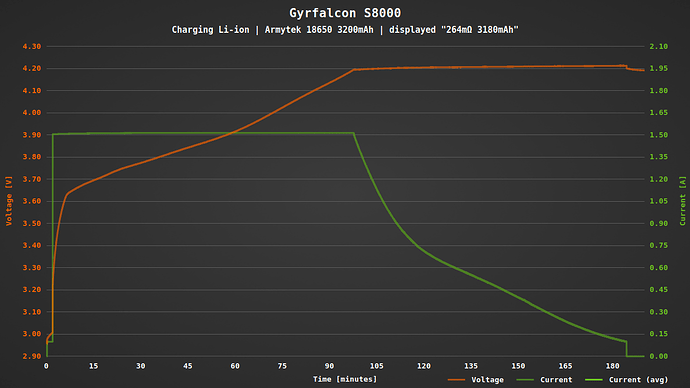

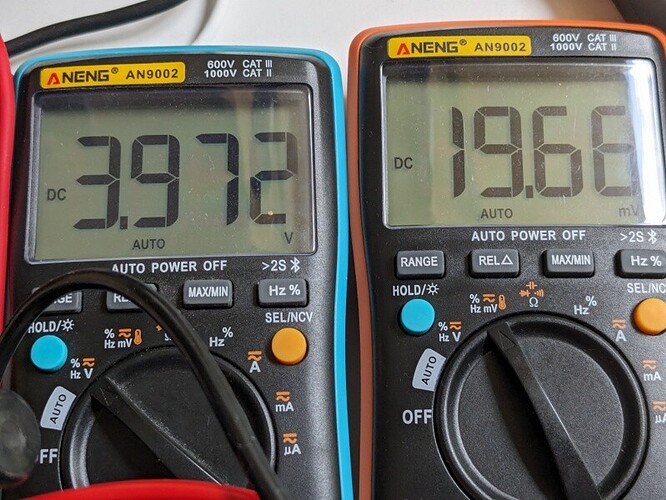

The following 1.5A lithium-ion battery charging curve is from SammysHP,thanks very much!! More details will be shared once he finished the Li-ion tests…

Hi BLF,

About storage modes, I’d like to hear everyone’s opinions. Please express your views on the following two specific implementation methods, which will ultimately determine which method we adopt.

The usual method is:

Storage mode should either charge or discharge to the specified voltage,Depending on if the voltage is lower or higher than the target voltage.

For example:

Target voltage: 3.600V

Chg Current: 1.000A

Dischg Curr: 0.500A

Battery voltage: 3.2V

Action: charge with 1.000A to 3.600V

Battery voltage: 3.9V

Action: discharge with 0.500A to 3.600V

This method is not applicable to Ni-Mh batteries.

The new method is:

Practically the similar as Cycle operation mode with setting D>C and N=1, first discharges, then charges to the target voltage, with rest in between. Reports charge capacities the end of the cycle.

For example:

Target voltage: 3.600V

Chg Current: 1.000A

Dischg Curr: 0.500A

Battery voltage: 3.2V

The first action: discharge with 0.500A to 3.000V

The second action: Rest for 15 minutes

The third action: charge with 1.000A to 3.600V

Battery voltage: 3.9V

The first action: discharge with 0.500A to 3.000V

The second action: Rest for 15 minutes

The third action: charge with 1.000A to 3.600V

Promote applicable to all supported battery types (including Ni-Mh batteries).

Different chemistries require different methods. Like Li-ion are charged with CC/CV, but NiMH with CC only with OCV measurement and different termination strategy.

The only useful storage mode for NiMH is to store them fully charged. Does anyone want a storage mode for NiMH? For Li-ion, charge/discharge them directly to the target voltage.

I would prefer Storage mode to identify the voltage of the cell and then for it to automatically decide whether it should charge or discharge.

The cell voltage might be 2.6V, 3V, 4.1V, 4.2V. The target would be 3.6V for Li-ion.

It would be nice if the charge and discharge current could be set.

500mA is a nice default.

User experience:

User inserts a cell configured to Storage mode.

Charger determines whether to charge or discharge and gets the cell to the target voltage.

No additional steps required.